Continuous tea dragon bead packaging production line

A packaging production line, tea dragon technology, applied in packaging, packaging machines, transportation packaging, etc., can solve the problems of low packaging efficiency, input a lot of manpower, material resources and time, saving manpower and time, improving market returns, and avoiding sealing Sexual Inadequate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

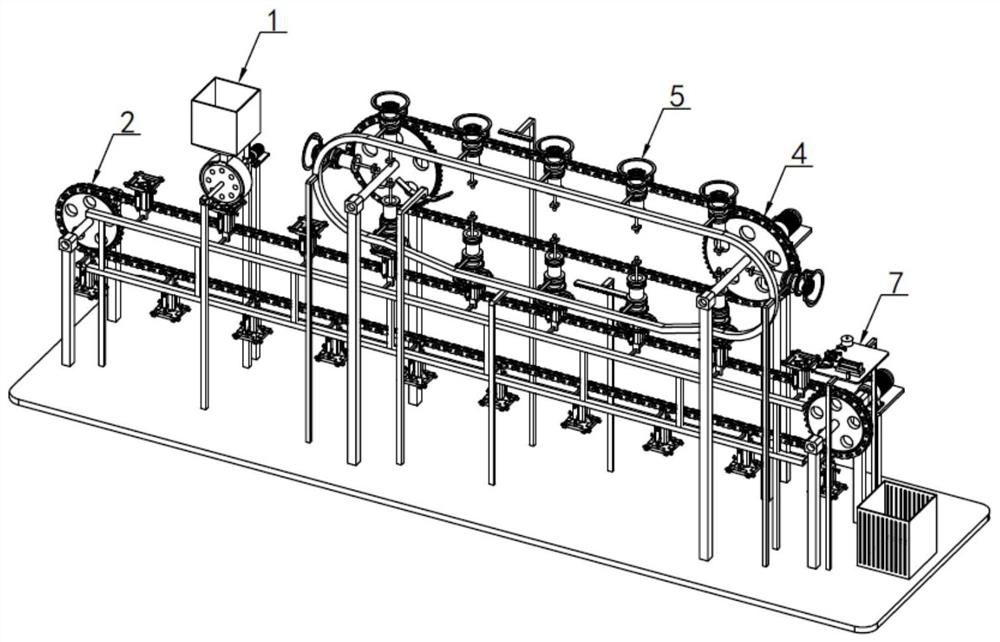

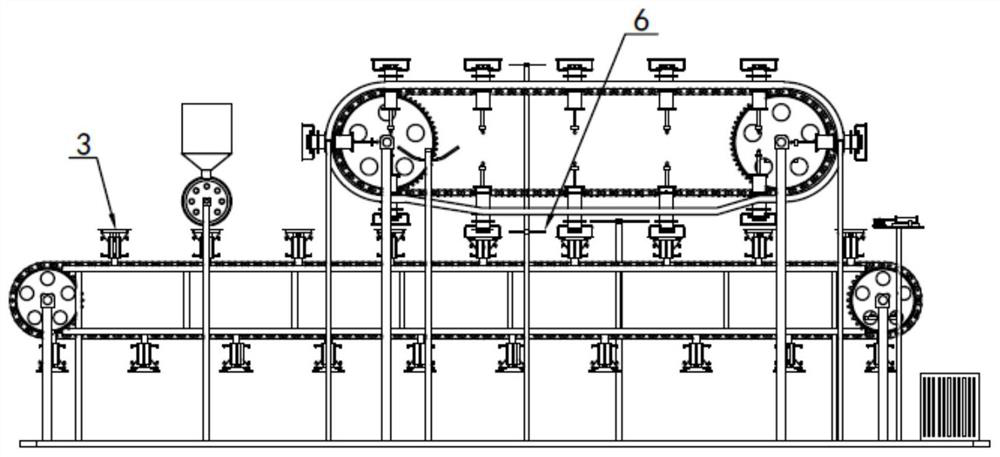

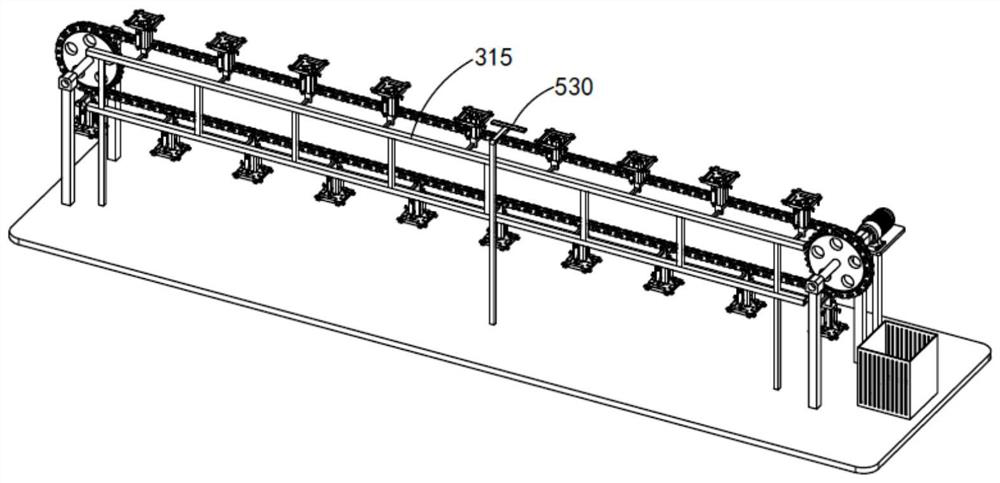

[0043] Such as Figure 1 to Figure 19 As shown, a continuous tea dragon ball packaging production line includes a feeding device 1, a first rotary device 2 is provided below the feeding device 1, and a plurality of equidistantly distributed wrapping mechanisms are arranged on the first rotary device 2 3. The wrapping mechanism 3 includes a limit assembly 301 and a support assembly 302, the limit assembly 301 is used to limit and support the wrapping paper, and the support assembly 302 is used to receive a single output from the feeding device 1 Tea dragon ball, the top of the first rotary device 2 is also provided with a matching second rotary device 4, and the second rotary device 4 is provided with a number of equidistantly distributed screw mechanisms 5, and the first rotary device 2 and the second rotary device 4 is formed with a screw channel 6, the screw mechanism 5 and the wrapping mechanism 3 move synchronously in the screw channel 6 one by one, the screw mechanism 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com