Rotor for a camshaft adjuster and camshaft adjuster

A camshaft adjuster and rotor technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of increasing costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

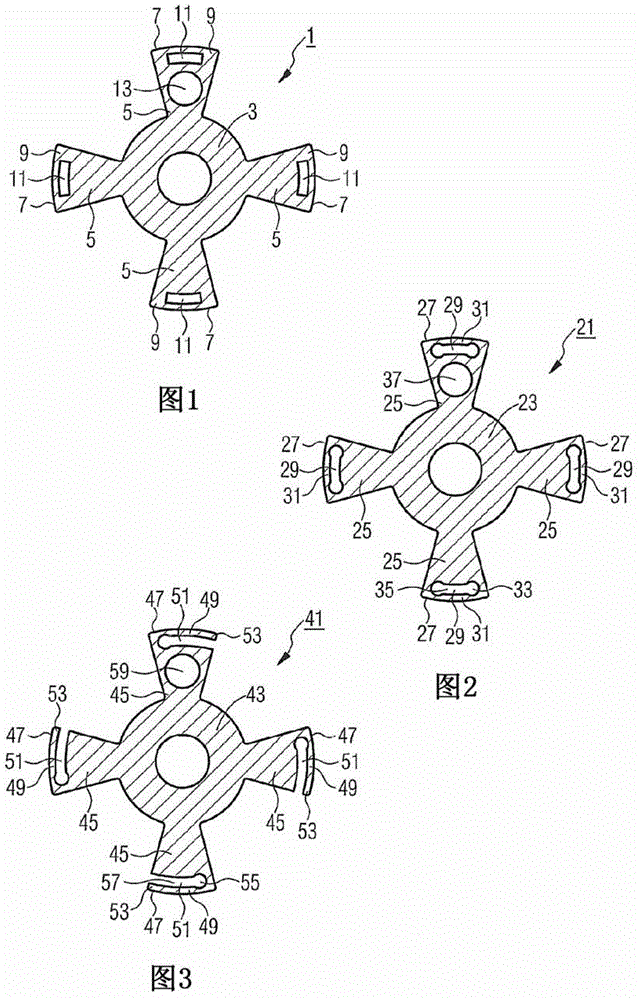

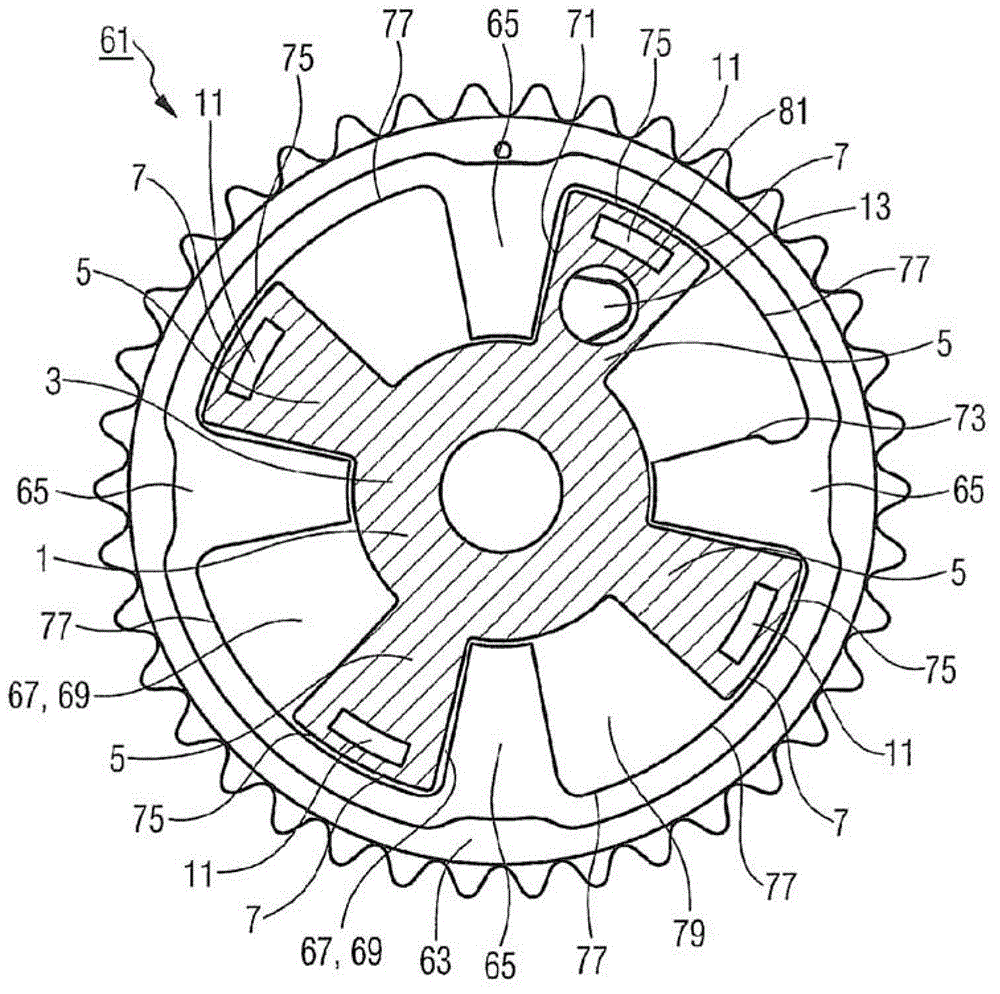

[0037] figure 1 The rotor 1 for a camshaft adjuster is shown in cross-section. The rotor 1 has a rotor base 3 with four rotor blades 5 extending radially outward. In the installed state, when the rotor 1 is positioned in the stator, the rotor blades 5 are used to divide each pressure chamber of the camshaft adjuster into two adjacent hydraulic regions. in Figure 4 The camshaft adjuster is shown in.

[0038] The rotor base 3 and the rotor blades 5 are integrally made of a metal material by a sintering method. Unlike the two-part manufacturing method in which the rotor blades 5 are held, for example, in grooves of the rotor base body 3, the possible leak locations are minimized by an integrated method. In addition, the sintering method provides the possibility of using an automated process flow, so it is cheap and easy to implement. Based on the dimensional accuracy of this method, the rotor 1 can be manufactured in such a way that the radial leakage gap between the blade end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com