Seal device of clothes dryer roller end

An end sealing and clothes dryer technology, which is used in household clothes dryers, washing devices, textiles and papermaking, etc., can solve the problems of the drum assembly error of the clothes dryer, the uneven radial sealing of the drum, and the effect of affecting the sealing effect of the drum. , to achieve uniform sealing effect, good sealing effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

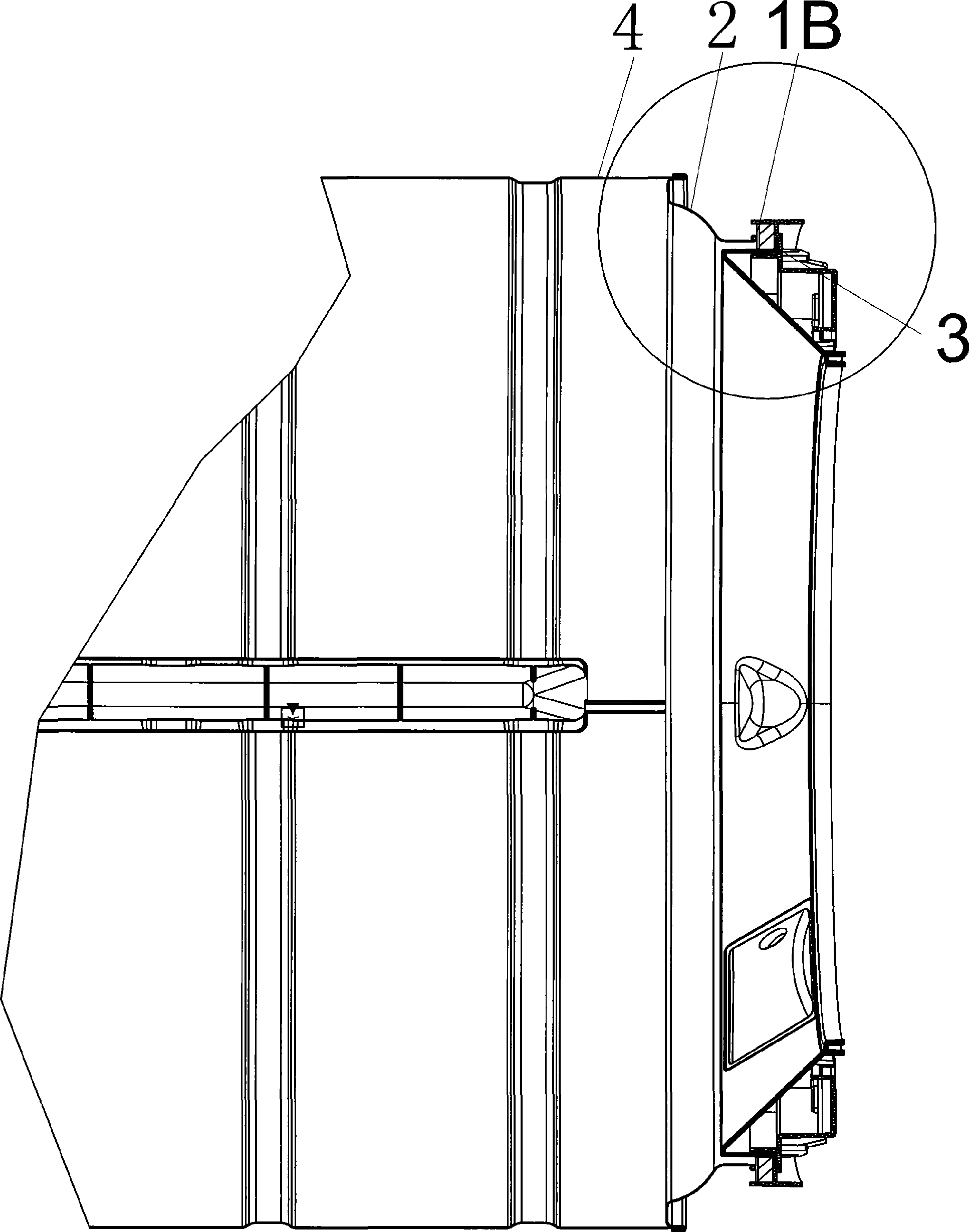

[0030] The present invention provides a sealing device for sealing the end of the drum of a clothes dryer, which seals the drum of a clothes dryer in the manner of sealing the axial end face of the drum. The sealing device in the present invention will be described in detail below in conjunction with the attached drawings The technical solution adopted.

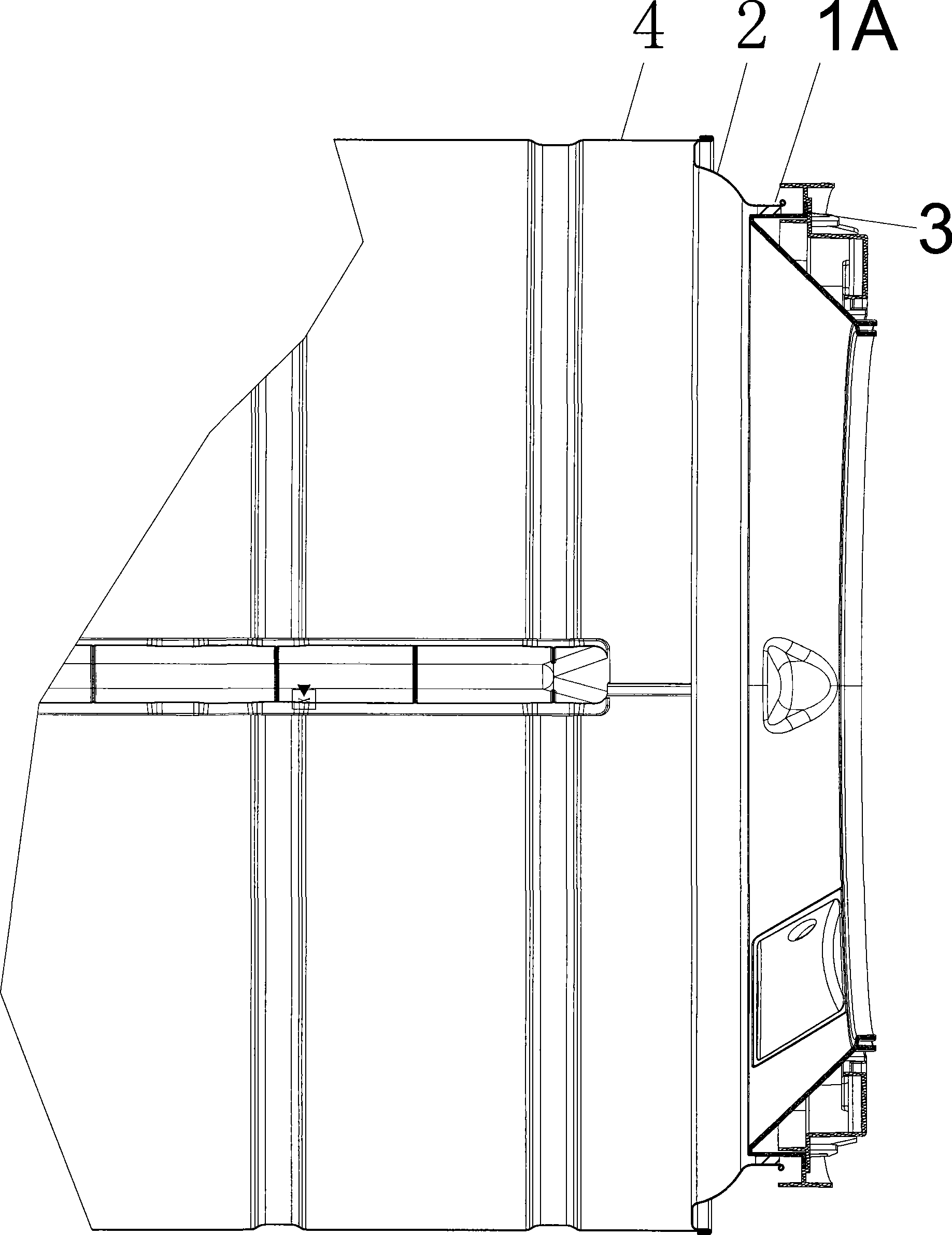

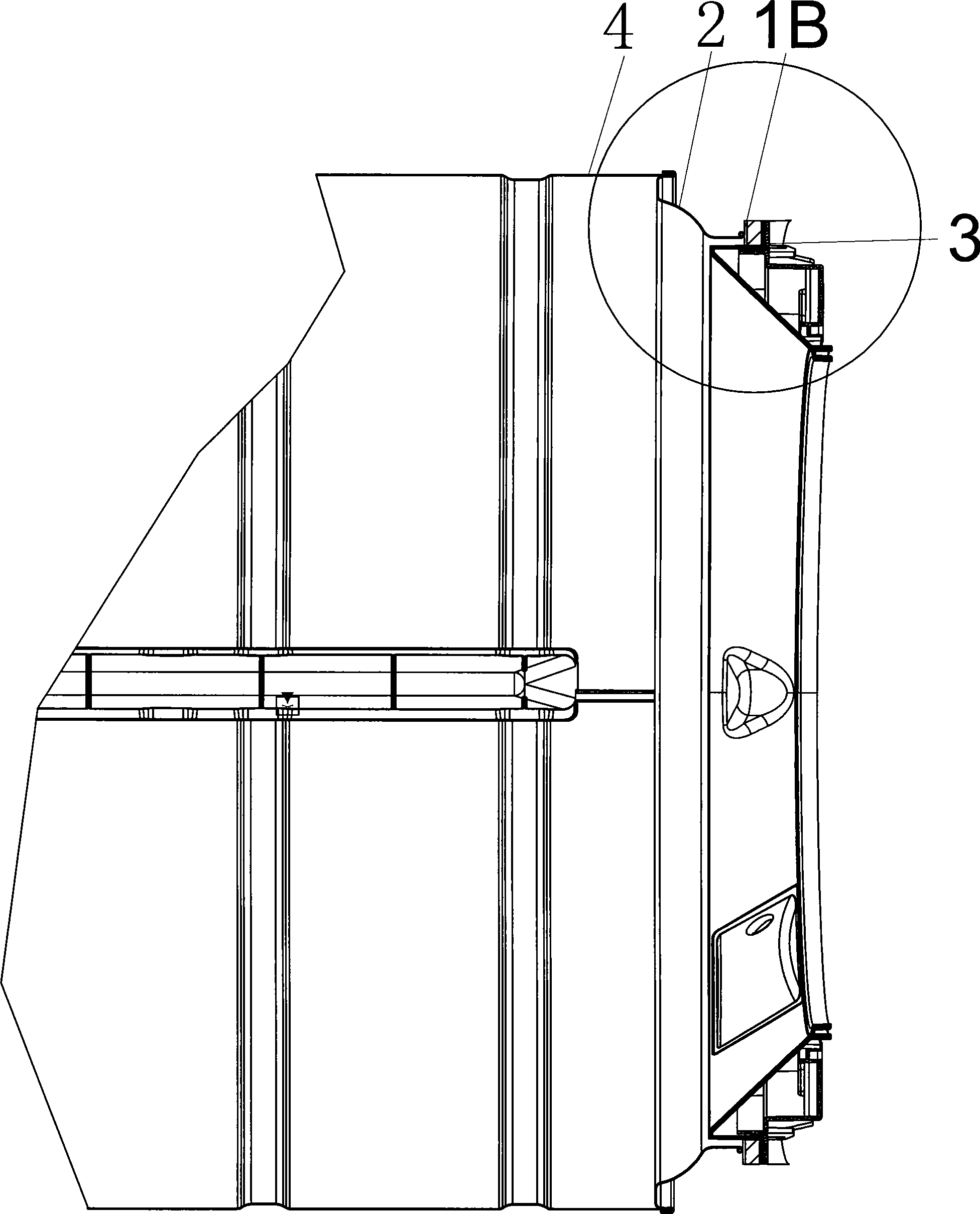

[0031] figure 1 Shown in is a schematic cross-sectional view of the sealing device at the end of the dryer drum in the prior art. In the prior art, an annular support ring 3 is arranged on the panel of the dryer, and the drum 4 is provided with a drum flange 2. The drum flange 2 is correspondingly arranged on the supporting ring 3, and the radial sealing strip 1A is evenly and fixedly arranged on the drum supporting ring 3, and the clothes dryer drum 4 is sleeved on the above supporting ring 3 so that the radial sealing strip 1A is in the drum method. Between the flange 2 and the supporting ring 3, the cylinder 4 is sealed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com