3D display panel, preparation method thereof, and 3D display device

A display panel and liquid crystal display panel technology, applied in the direction of optical components, optics, instruments, etc., can solve the problems affecting the firmness of the spacer glass and the display panel, poor light uniformity, and affecting the 3D display effect, so as to improve the firmness and The effect of the uniformity of the outgoing light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

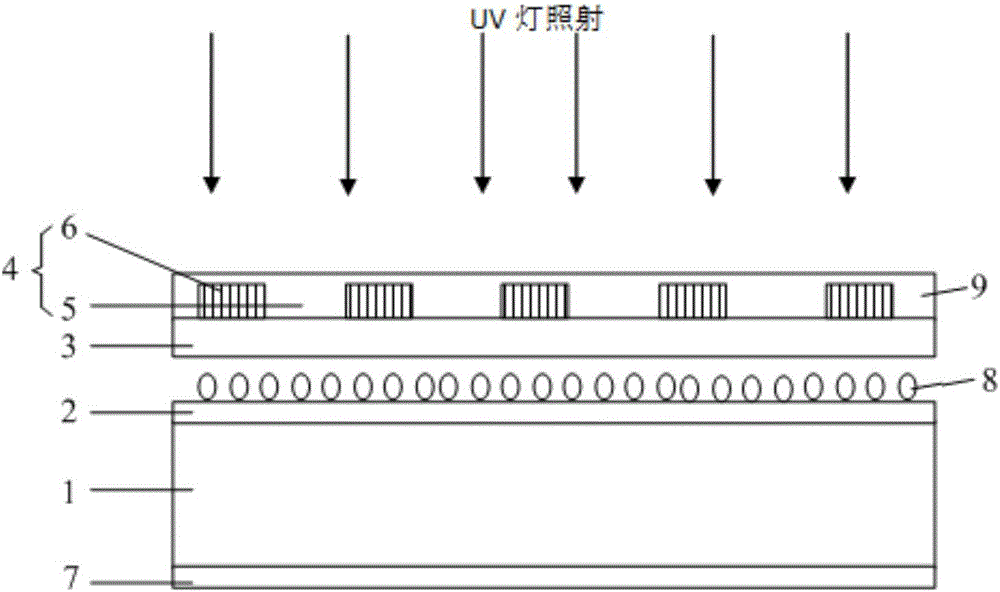

[0037] figure 1 This is a schematic structural diagram of a 3D display panel provided in the first embodiment of the present invention, such as figure 1 As shown, the 3D display panel includes: a 2D display panel 1, a first polarizer 2, a spacer substrate 3, and a polarizing layer 4. The first polarizer 2 is located on one side of the 2D display panel 1, and the spacer The bottom 3 is located on the side of the first polarizer 2 facing away from the display panel, and the polarizing layer 4 is located on the side of the spacer substrate 3 facing away from the first polarizer 2. The polarizing layer 4 includes: a number of light-transmitting regions 5 and a number of polarizing regions. The light-transmitting regions 5 and the polarizing regions are arranged alternately and in parallel. Each polarizing region is provided with a polarizing structure 6 and all the polarizing structures 6 are arranged in parallel; The sheet 2 has a first polarization axis, the polarization structure...

Embodiment 2

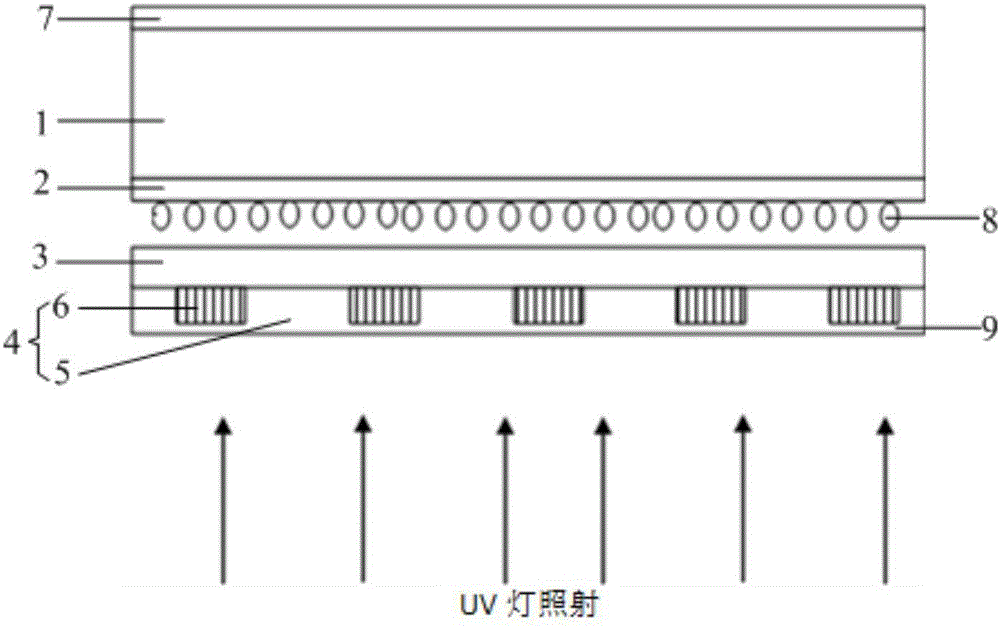

[0050] image 3 It is a schematic structural diagram of a 3D display panel provided in the second embodiment of the present invention, such as image 3 As mentioned, the difference from the first embodiment above is that the 2D display panel 1 in this embodiment can only be a liquid crystal display panel, and the first polarizer 2 is attached to the light incident side of the 2D display panel 1 at this time.

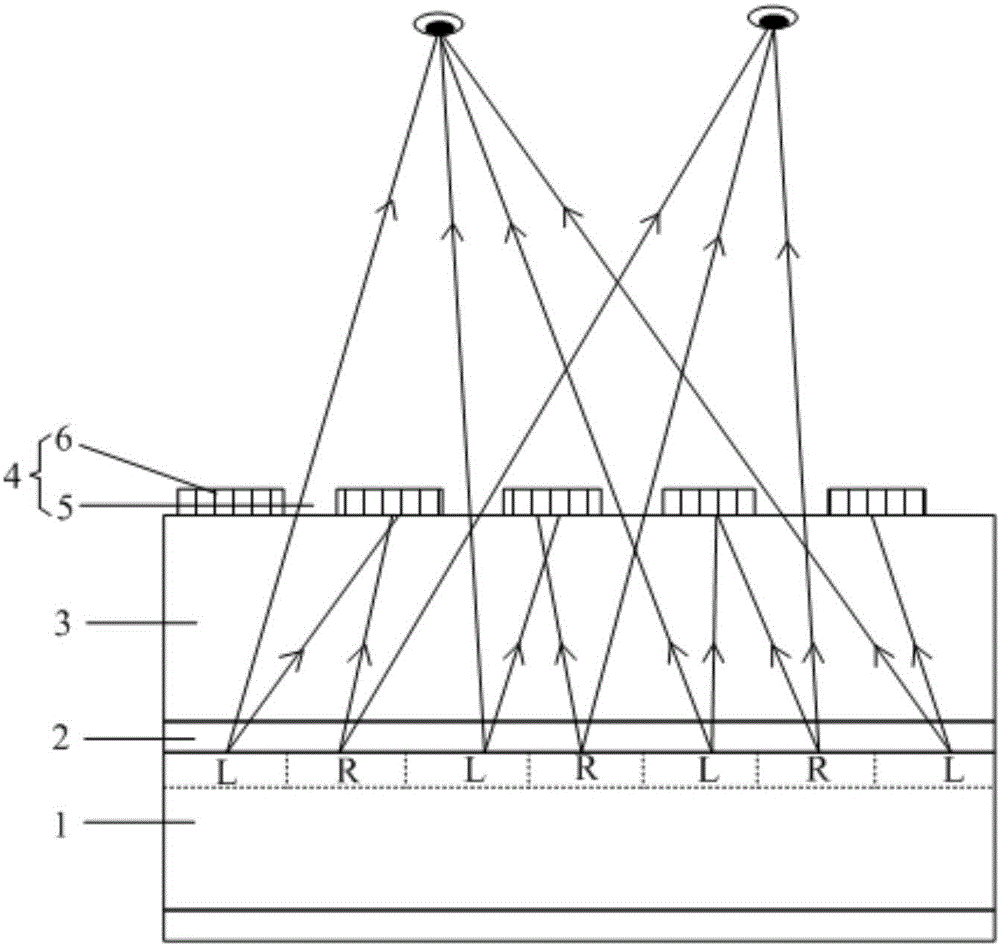

[0051] Figure 4 for image 3 The light path diagram of the 3D display panel shown in 3D display, such as Figure 4 As shown, when the 3D display panel provided in this embodiment performs display, the light generated by the backlight source (not shown) will first be emitted to the polarizing layer 4. Wherein, the light directed to the light-transmitting area 5 of the polarizing layer 4 will be directly transmitted from the light-transmitting area 5, and pass through the spacer substrate 3, the first polarizer 2 and the 2D display panel 1 in sequence, and be directed to the e...

Embodiment 3

[0056] Figure 5 This is a flowchart of a method for manufacturing a 3D display panel provided in the third embodiment of the present invention, such as Figure 5 As shown, the preparation method is used to prepare the 3D display panel in the foregoing embodiment 1 and embodiment 2, and the preparation method includes:

[0057] Step 101: Prepare a 2D display panel, and arrange a first polarizer on one side of the 2D display panel.

[0058] In step 101, an existing liquid crystal display panel manufacturing process or an OLED display panel manufacturing process can be used to prepare a 2D display panel. Wherein, when the 2D display panel is an OLED display panel, the first polarizer needs to be attached to the light-emitting side of the OLED display panel; when the 2D display panel is a liquid crystal display panel, it is necessary to attach the first polarizer on both sides of the liquid crystal display panel. The first polarizer and the second polarizer are attached, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com