Method for detecting tensile breaking force of polyacrylonitrile-based carbon fiber cloth

A technology of polyacrylonitrile-based carbon fiber and tensile fracture, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as complicated operation and inaccurate test results, so as to ensure consistency, improve authenticity and Reliability and high consistency of data results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

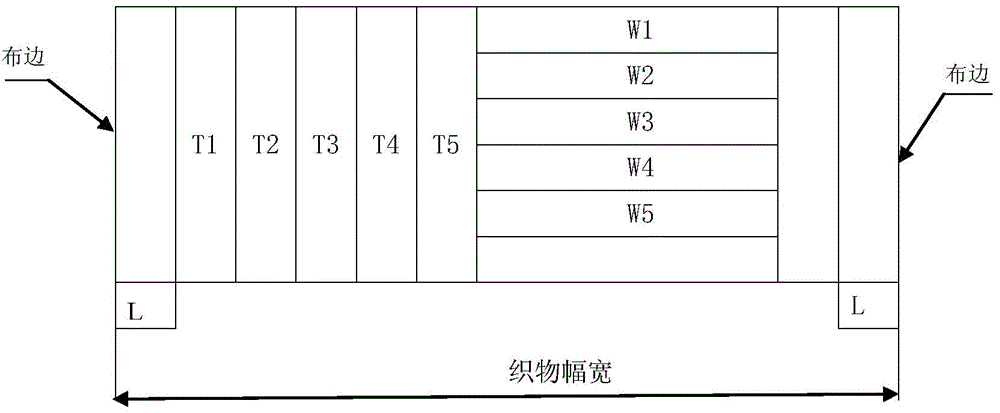

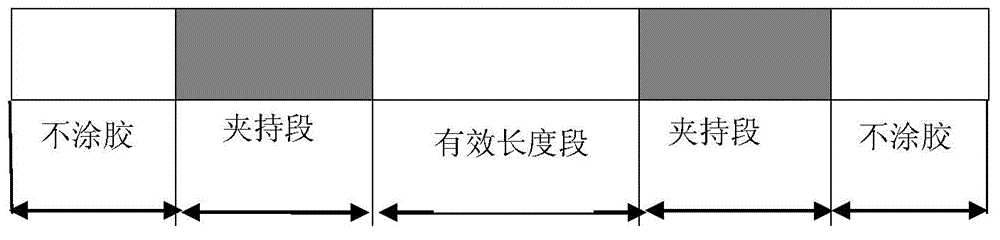

[0024] The polyacrylonitrile-based carbon fiber cloth tensile breaking strength testing method of the present invention includes three steps of sampling, sample processing and tensile testing. According to GB / T7689.2 "Reinforcing materials, woven fabric test methods (Part 2) Determination of warp and weft density" by cutting out respectively 5 warp and weft samples in this preferred embodiment, determine the jaw width of the testing machine The number of inner yarns, remove the excess yarn on the sample, apply glue on both ends of the sample to strengthen the clamping section, use flat jaws on the universal testing machine, and line rubber on both sides of the clamping section Pad, stretch the sample at a constant speed, record the maximum force applied when the sample breaks, and take the av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com