Aluminum foil composite heat-proof sleeve and manufacturing method thereof

A heat-proof sleeve and composite technology, which is applied to heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of inconvenient tooling, increased weight, loose heat-resistant materials, etc., and achieve stable protection effect and molding fit Good performance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

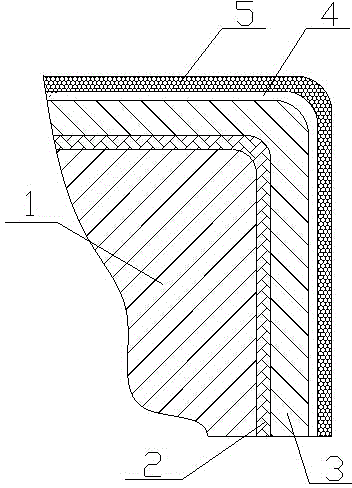

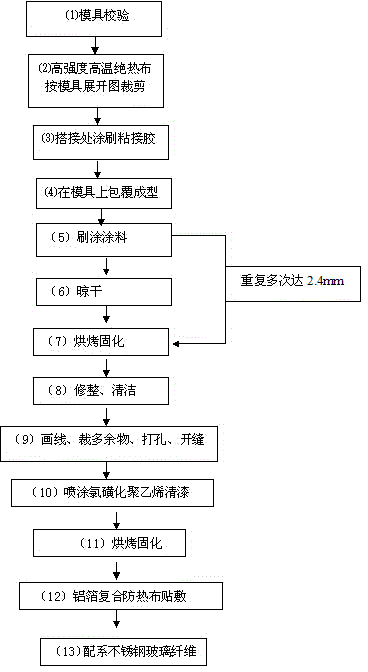

[0014] like figure 1 As shown, the preferred embodiment of the present invention about the aluminum foil composite heat-proof cover is: the bottom layer of the heat-proof cover made of 0.3mm thick high-temperature heat-insulating cloth 2 is wrapped on the mold 1, and the high-temperature heat-insulating cloth 2 is placed on the surface of the instrument. There is an overlapping edge at the corner, and a continuous polyurethane heat-insulating coating layer 3 with a thickness of 2.4mm is painted on the outer surface of the high-temperature heat-insulating cloth 2, and a varnish layer 4 is sprayed on the outside of the polyurethane heat-insulating coating layer 3 and the end surface of the heat-proof sleeve An aluminum foil composite thermal insulation film 5 is pasted on the outside of the varnish layer 4, and the heat-proof sleeve is provided with a crack arresting hole and a stringing hole, and a stainless steel fiberglass rope runs through the stringing hole.

[0015] The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com