Manufacturing process for cylinder battery

A manufacturing process and cylindrical battery technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, sustainable manufacturing/processing, etc., can solve problems such as poor sealing effect, electrolyte outflow, waste of raw materials, etc., to reduce process steps and Material cost, good sealing effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

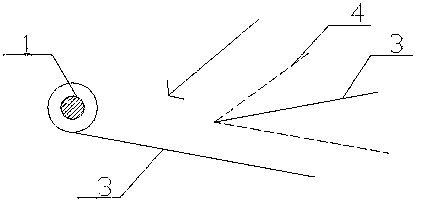

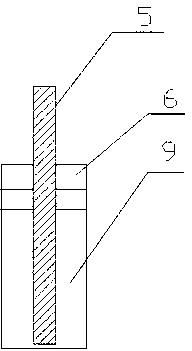

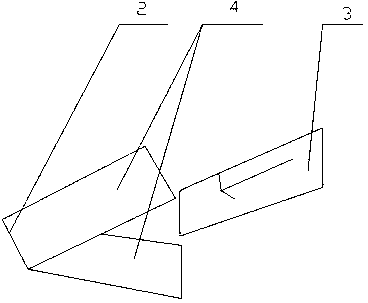

[0028] A manufacturing process of a cylindrical battery, firstly carry out the manufacturing process of the battery coiling pin: first, the coiling pin 1 (such as figure 1 shown) welded to the positive or negative plate, in figure 1 The positive electrode plate or the negative electrode plate mentioned in the above is represented by the serial number 3, and then a circular insulating plate with a diameter equal to the inner diameter of the battery is connected in series from the upper end of the needle where the positive electrode plate or the negative electrode plate is not welded ( 8), in Figure 4 shown in ; the rolling needle passes through the circular insulating plate and the part that passes through is drawn out to the outer surface of the battery to become the positive terminal or negative terminal of the battery, and the positive terminal or negative terminal is in figure 2 Indicated by serial number 5;

[0029] Then carry out the battery winding process: insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com