Rock debris sample containing device and rock debris casting slice making method using same

A cuttings and system technology, applied in the field of petroleum exploration, can solve the problems of chaotic samples, affecting pore observation, and inability to make casting pieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

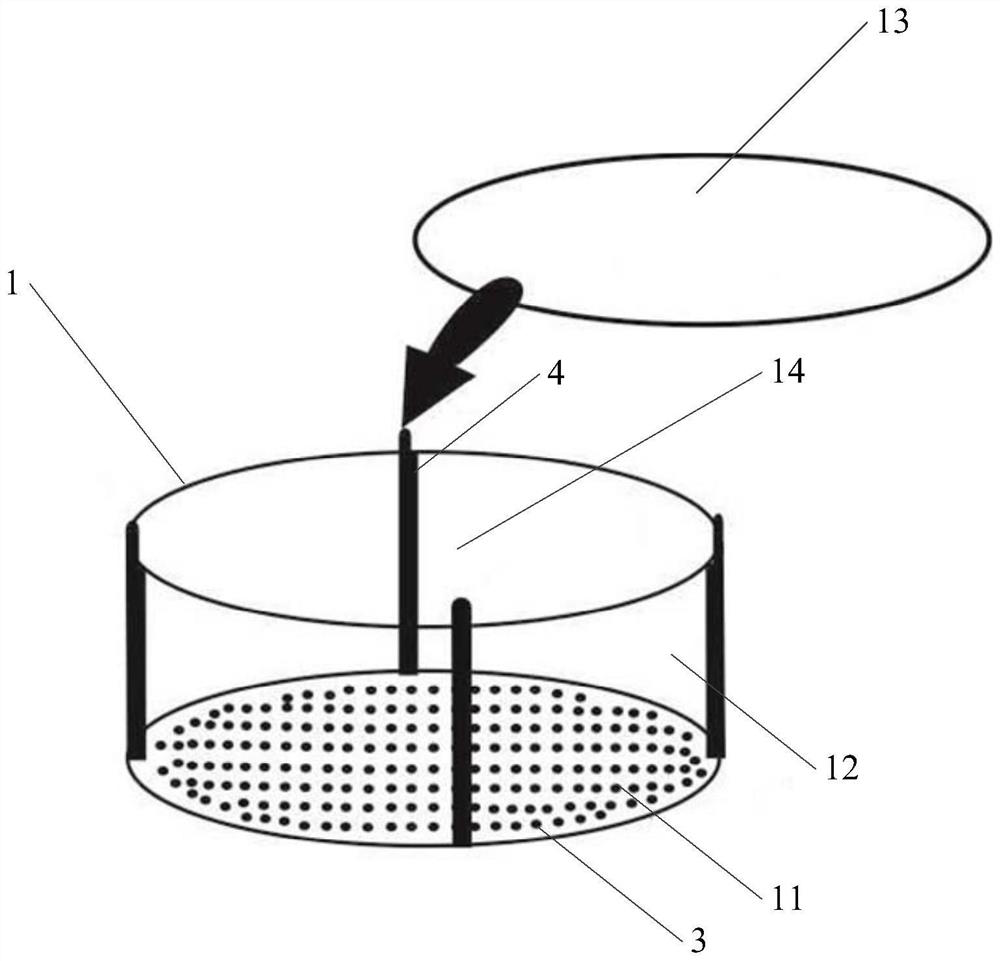

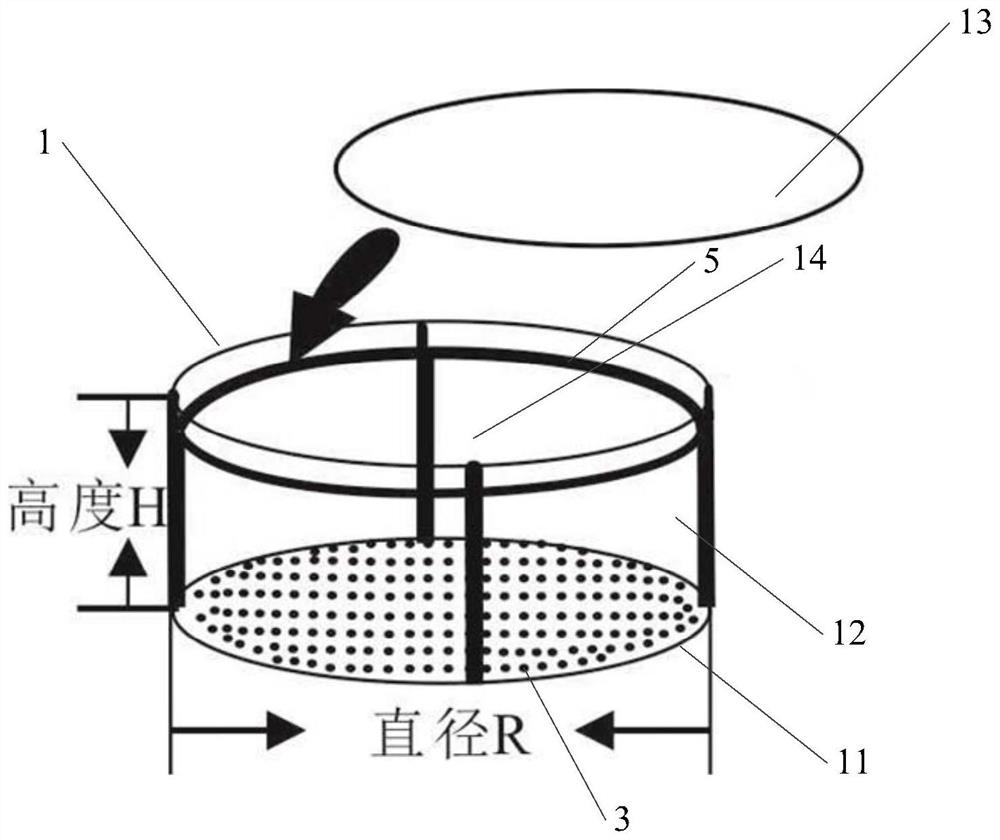

[0131] This embodiment provides a method for slicing rock cuttings castings, comprising the following steps:

[0132] 1) Pretreatment of cuttings samples: The cuttings samples used in this example are Antan 1X Ordovician Majiagou Formation cuttings samples in the Jizhong Depression of PetroChina Huabei Oilfield Company;

[0133] Specifically include:

[0134] i) Cleaning: Use anhydrous ethanol reagent to wash away pollutants such as mud, oil gas and asphalt during the sampling process;

[0135] ii) drying: put the cleaned rock chip sample in a glass container, and bake the glass container at a temperature of 110°C for 12 hours;

[0136] iii) Screening: The dried cuttings samples are screened according to cuttings characteristics (comprising cuttings sampling depth, cuttings uniformity and cuttings particle size), because the cuttings samples selected in this embodiment are relatively small, more It is sub-millimeter-micron level, so pour the cuttings samples on standard A4 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com