Extruder

An extruder and barrel technology, applied in the field of extruders, can solve the problems of substandard quality inspection, affecting appearance, carbonization, etc., achieving substandard rate and reducing scrap rate, good orientation coordination, and improved product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

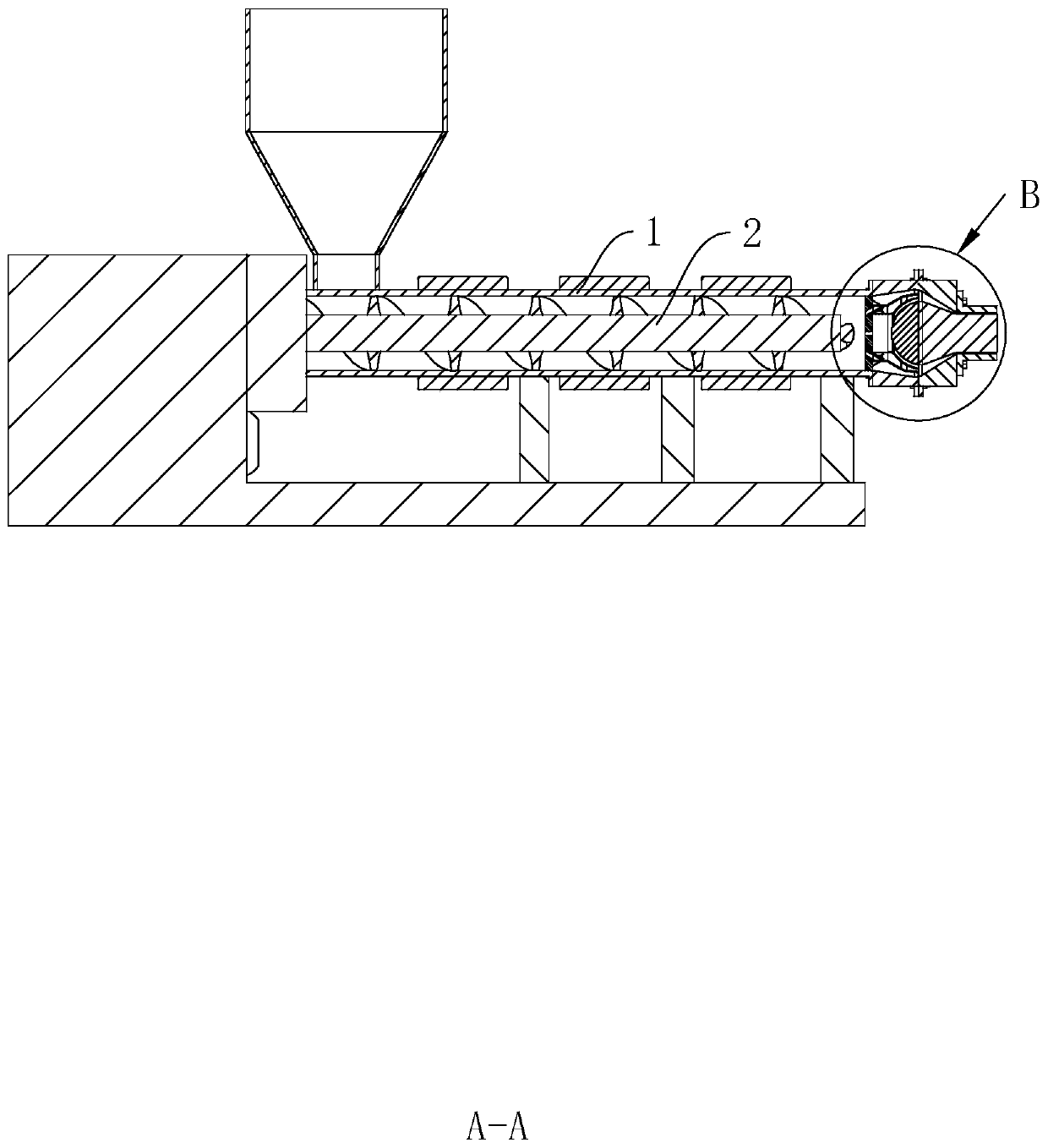

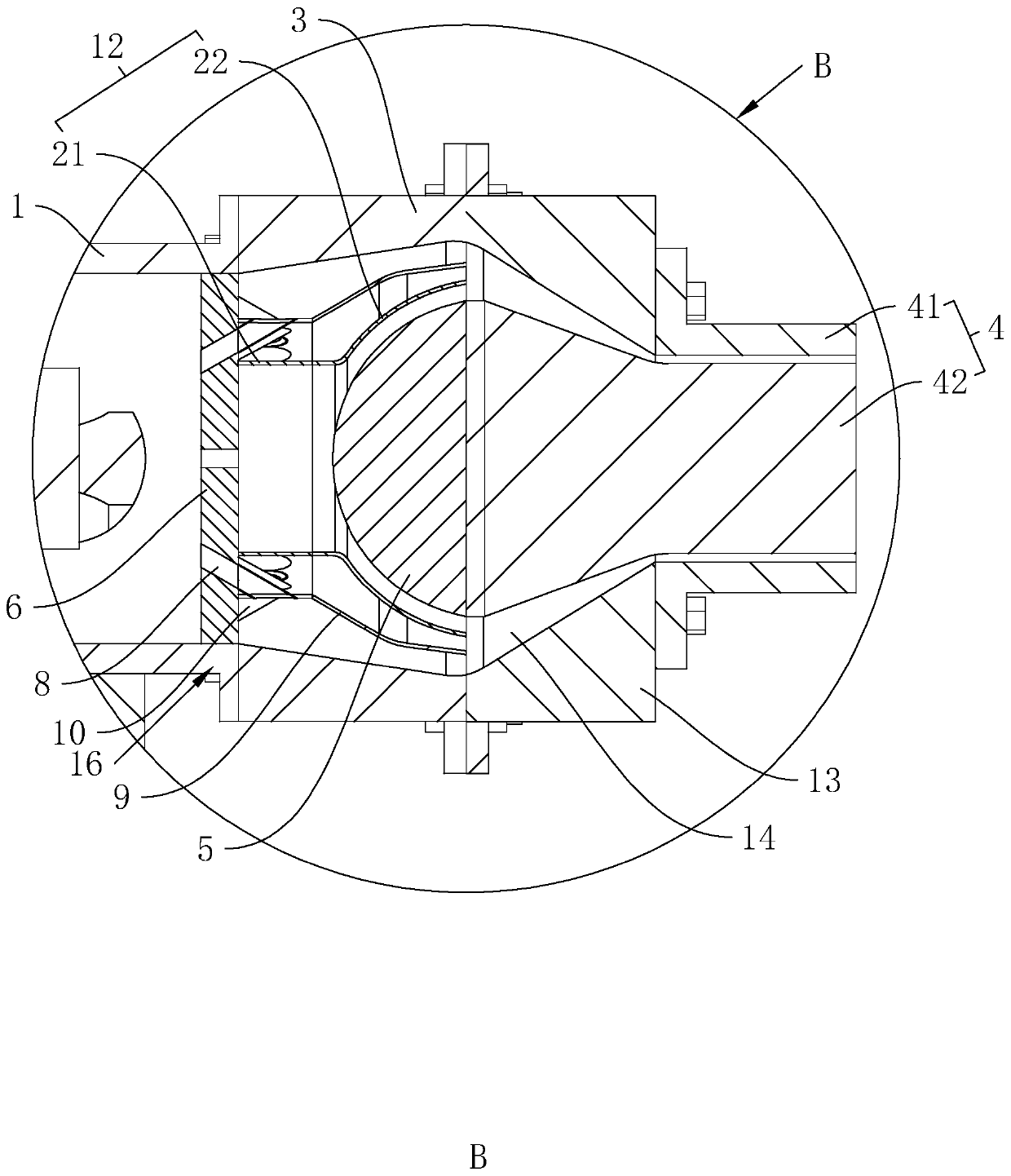

[0035] The present invention will be further described in detail below with reference to the accompanying drawings.

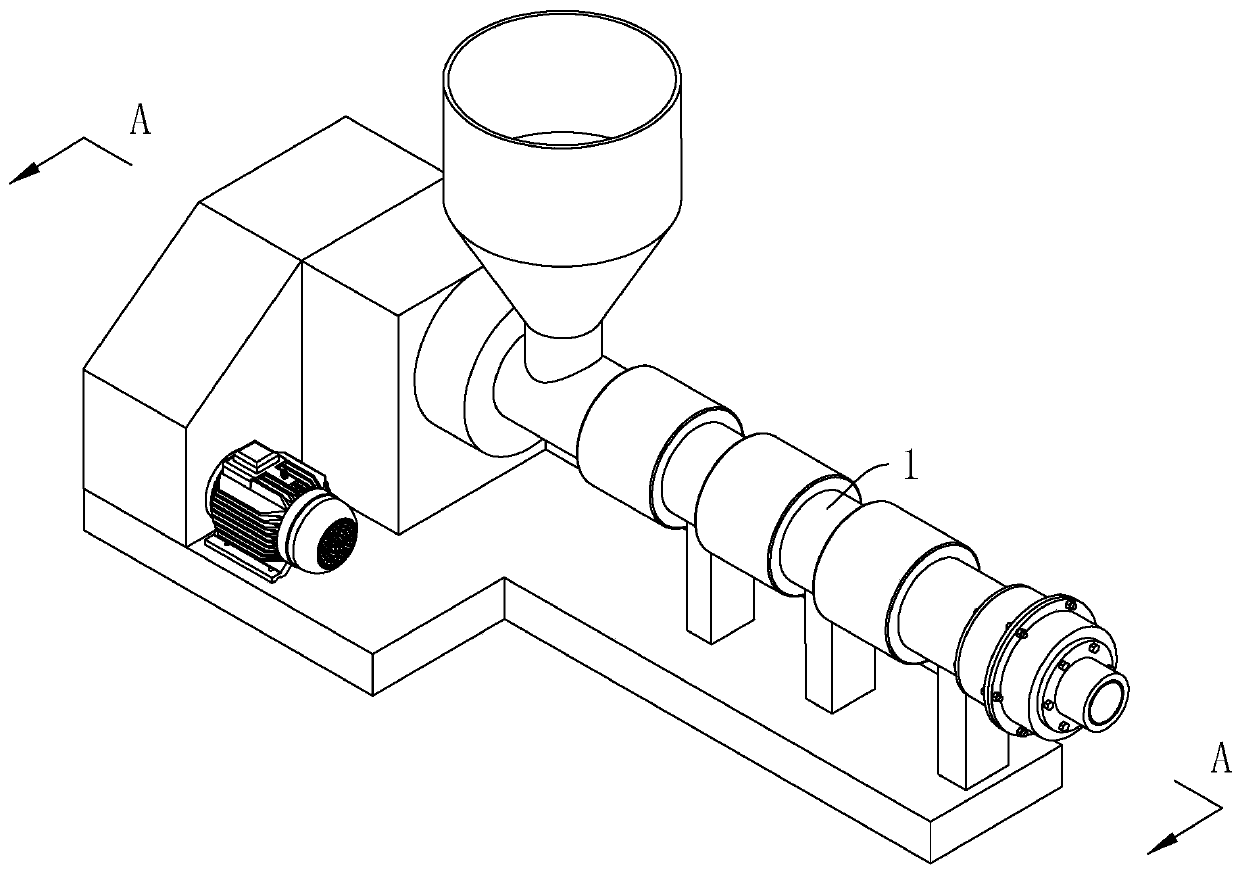

[0036] refer to figure 1 and figure 2 , is an extruder disclosed in the present invention, comprising a barrel 1, the inner diameter of the barrel 1 is cylindrical and arranged horizontally, a three-section screw 2 is rotated in the barrel 1 by a driving device, and the circumference of the screw 2 is arranged. It rotates and abuts with the inner wall of the barrel 1. The operator first adds the raw material particles for producing the pipe to the barrel 1 through the feeding hopper, and then starts the driving device to drive the screw 2 to rotate in the barrel 1 while conveying the raw materials. The material passes through the machine. The interval heating provided on the peripheral wall of the barrel 1 is melted and plasticized into a solution, which is gradually transferred to the port on the other side of the barrel 1 for storage.

[0037] refer to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com