Ultraviolet light/heating double-curing adhesive

A dual-curing and adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low bonding strength of LCP and inability to achieve fast deep curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

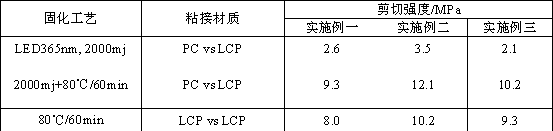

Examples

Embodiment 1

[0028] Add 50 parts of 830LVP epoxy resin into the reaction kettle and heat it up to 120°C, with a stirring speed of 150r / min; add 10 parts of liquid crystal epoxy resin YS-400H under this temperature and stirring conditions and continue stirring for 90 minutes; wait until it is evenly stirred After cooling down to 95°C, add 10 parts of M521 core-shell rubber toughened particles, continue to stir and react for 120 minutes under the condition of 100r / min, stop heating and cool to room temperature, add 20 parts of acrylate SR833 and 10 parts of CN704, 1 part of TPO, 0.5 parts of dibenzoyl peroxide, 20 parts of FXR-1020 and high-speed stirring for 2 hours, after the glue is stirred evenly, add 3 parts of fumed silicon R202, and stir for 3 hours at a temperature of 25 ° C, a vacuum of -0.1 MPa, and a high speed to obtain finished product.

Embodiment 2

[0030] Add 40 parts of Epikote828 and 15 parts of chelating type EP-49-10P2 epoxy resin into the reaction kettle and heat it up to 150°C with a stirring speed of 200r / min; add 15 parts of liquid crystal ring under this temperature and stirring conditions Continue to stir the oxygen resin SE-500 for 70 minutes; after stirring evenly, cool down to 95°C and add 10 parts of M711 core-shell rubber toughening particles, continue to stir and react for 120 minutes under the condition of 150r / min, stop heating and cool to room temperature, then add 10 parts DMAA, 15 parts of CN966NS, 1 part of 184, 0.5 part of peroxydicarbonate bis(4-tert-butylcyclohexyl), 30 parts of EH-5057P high-speed stirring for 2 hours, after the glue is stirred evenly, add 8 parts of fumed silicon R8200 , at a temperature of 25°C, a vacuum of -0.1MPa, and high-speed stirring for 3 hours to obtain the finished product.

Embodiment 3

[0032] Add 40 parts of YD-114F and 10 parts of EP-49-10N epoxy resin into the reaction kettle and heat it up to 120°C with a stirring speed of 150r / min; add 5 parts of liquid crystal epoxy resin under this temperature and stirring conditions Resin SE-650 continues to stir for 90 minutes; after stirring evenly, cool down to 95°C and add 10 parts of M732 core-shell rubber toughened particles, continue stirring and reacting for 120 minutes under the condition of 100r / min, stop heating and cool to room temperature, then add 30 parts of SR506NS, 1 part of 184, 0.5 part of bis(4-tert-butylcyclohexyl) peroxydicarbonate, 30 parts of EH-5031S and high-speed stirring for 2 hours, after the glue is stirred evenly, add 5 parts of fumed silicon R202, at a temperature of 25 ° C, Vacuum degree -0.1MPa, high-speed stirring for 3 hours, the finished product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com