Novel steel pipe outer surface 3PE full powder anticorrosion production line and anticorrosion technology

An external surface, all-powder technology, used in special surfaces, pretreatment surfaces, devices for coating liquids on surfaces, etc., can solve the problems of uneven thickness of steel pipe 3PE coating, steel pipe welds, etc., to ensure solidification and leveling. , low energy consumption, the effect of power and heat uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

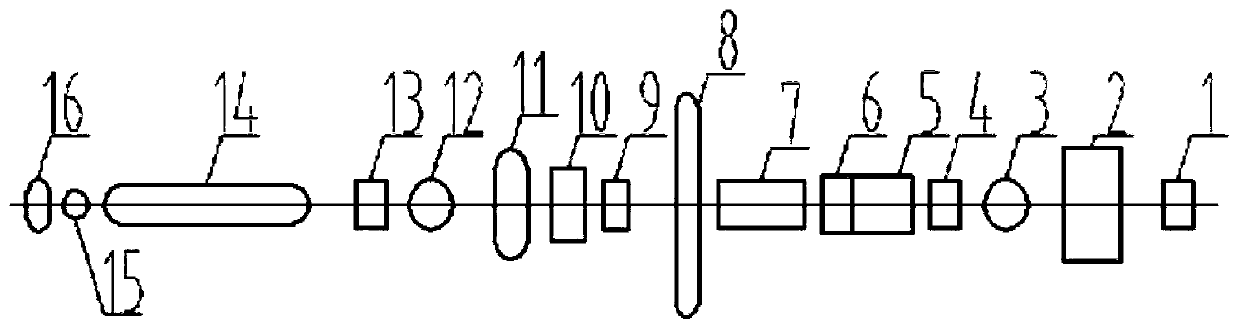

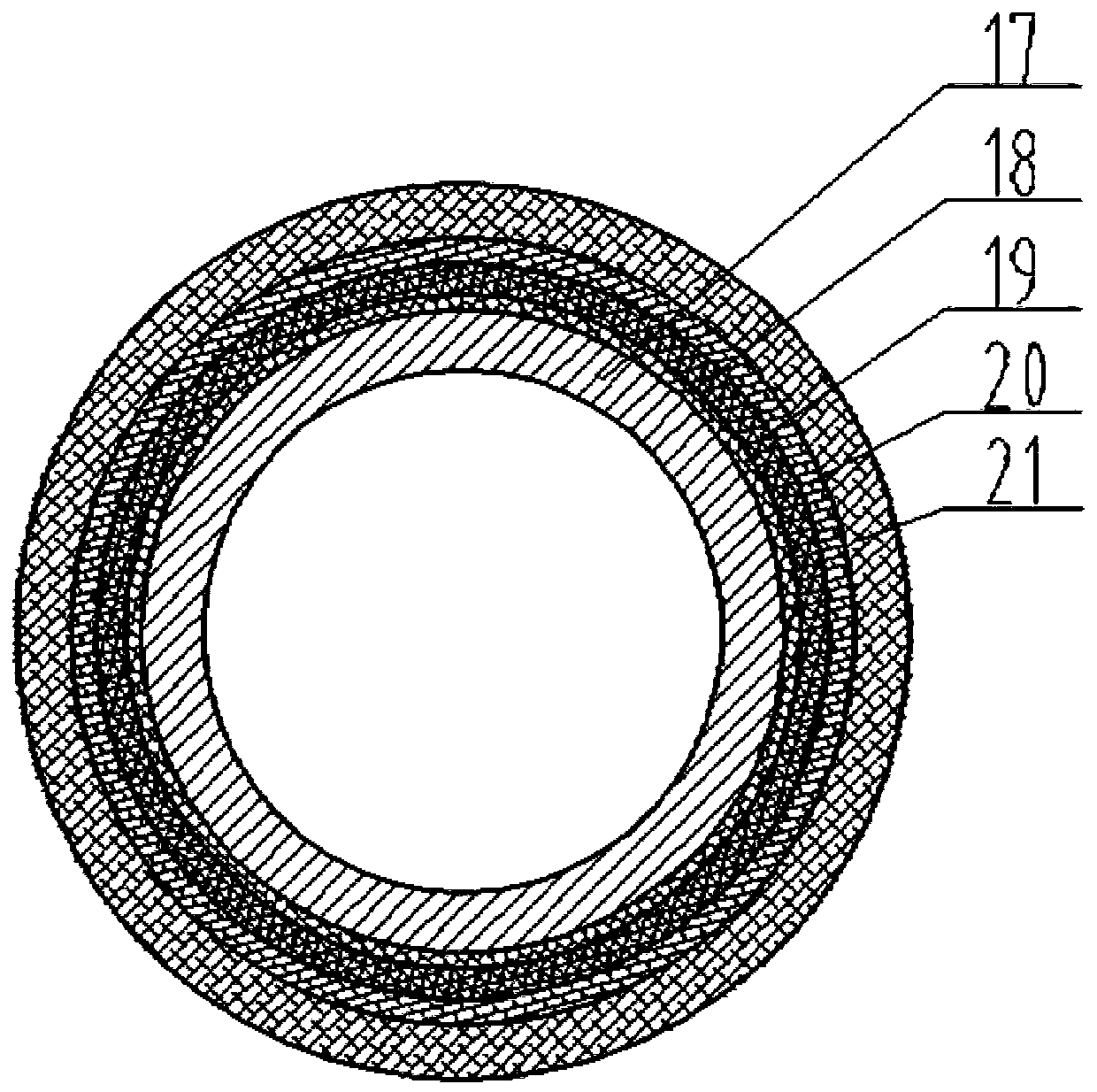

[0042] A new type of 3PE full powder anti-corrosion production line for the outer surface of steel pipes, see figure 1 , figure 2 , the production line consists of a flame preheating furnace 1, a shot blasting derusting machine 2, a pipe cleaning device 3, an intermediate frequency heating furnace I4, a pickling and phosphating chamber 5, a high-pressure water cleaning and air-drying chamber 6, and an intermediate frequency heating furnace Ⅱ7. Epoxy powder electrostatic spraying device 8. Coating heating furnace Ⅰ9. Adhesive powder coating device 10. Coating heating furnace Ⅱ11. Polyethylene powder coating device 12. Coating leveling furnace 13. Water cooling device 14. EDM The leak detection device 15 and the pipe end grinding device 16 are composed. Through epoxy powder electrostatic spraying device 8, adhesive powder shower coating device 10 and polyethylene powder shower coating device 12, the outer layer of steel pipe is sprayed with epoxy powder electrostatic spray coa...

Embodiment 2

[0061] A new type of 3PE full powder anti-corrosion production line for the outer surface of steel pipes, see figure 1 , figure 2 , the production line consists of a flame preheating furnace 1, a shot blasting derusting machine 2, a pipe cleaning device 3, an intermediate frequency heating furnace I4, a pickling and phosphating chamber 5, a high-pressure water cleaning and air-drying chamber 6, and an intermediate frequency heating furnace Ⅱ7. Epoxy powder electrostatic spraying device 8. Coating heating furnace Ⅰ9. Adhesive powder coating device 10. Coating heating furnace Ⅱ11. Polyethylene powder coating device 12. Coating leveling furnace 13. Water cooling device 14. EDM Leak detection device 15 and pipe end grinding device 16 are composed of epoxy powder electrostatic spraying device 8, adhesive powder shower coating device 10 and polyethylene powder shower coating device 12 of a new type of steel pipe outer surface 3PE full powder anticorrosion production line. The oute...

Embodiment 3

[0080] A new type of 3PE full powder anti-corrosion production line for the outer surface of steel pipes, see figure 1 , figure 2 , the production line consists of flame preheating furnace 1, shot blasting derusting machine 2, pipe cleaning device 3, intermediate frequency heating furnace I4, pickling and phosphating chamber 5, high pressure water cleaning and air drying chamber 6, intermediate frequency heating furnace Ⅱ7. Epoxy powder electrostatic spraying device 8. Coating heating furnace Ⅰ9. Adhesive powder coating device 10. Coating heating furnace Ⅱ11. Polyethylene powder coating device 12. Coating leveling furnace 13. Water cooling device 14. EDM Leak detection device 15 and pipe end grinding device 16 are composed of epoxy powder electrostatic spraying device 8, adhesive powder shower coating device 10 and polyethylene powder shower coating device 12 of a new type of steel pipe outer surface 3PE full powder anticorrosion production line. The outer layer of the steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com