PCB mounting process and mounting glue applied to mounting process

A technology of PCB board and patch glue, which is applied in the direction of assembling printed circuit of electrical components, electrical components, printed circuit manufacturing, etc. It can solve the problem of indetermination of curing temperature of epoxy resin, weakening of transition metal ion activity, and inability to guarantee the degree of curing And other problems, to speed up the light curing speed, reduce the time, reduce the effect of irreversible damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

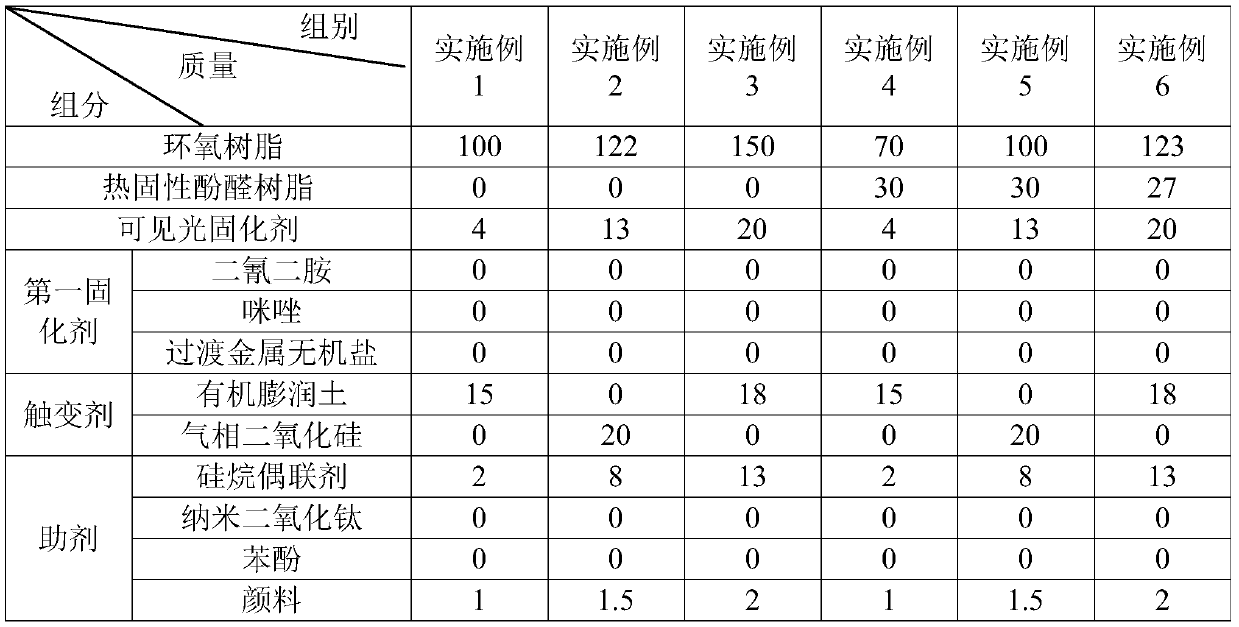

[0048] Example 1-12: A patch adhesive. The components included in Examples 1-6 and the corresponding masses are shown in Table 1, and the components and corresponding masses included in Examples 7-12 are shown in Table 2. And made by the following steps:

[0049] Step 1: Mix the epoxy resin, thermosetting phenolic resin, thixotropic agent, and auxiliary agent, stir at 300r / min for 2h under the environment of 30±1℃ and the vacuum degree of 0.05MPa to obtain the mixture A;

[0050] Step 2: Add the visible light curing agent and the first curing agent to the mixture A, and stir at 50r / min for 1h in a closed environment.

[0051] Table 1 Example 1-6 components and corresponding mass (kg)

[0052]

[0053] Table 2 Example 7-12 components and corresponding mass (kg)

[0054]

[0055] In the above embodiment,

[0056] The visible light curing agent is obtained by mixing the diaryliodonium salt and the dye at a weight ratio of 2:1.

[0057] The transition metal inorganic salt in Examples 7-9 is ...

Embodiment 13

[0059] Embodiment 13: A PCB board placement process, including the following steps:

[0060] S1: Print solder paste on the A side of the PCB board;

[0061] S2: Place the adhesive on the A side of the PCB board, mount the components on the A side, and enter the reflow oven with the A side up for reflow soldering;

[0062] S3: Print solder paste on the B side of the PCB, mount the components on the B side, and enter the reflow oven with the B side up for reflow soldering;

[0063] Illumination equipment is installed on both sides of the inner cavity of the reflow oven, the illumination equipment is located on both sides of the conveyor belt, and the illumination equipment is installed in front of the reflow soldering area;

[0064] The residence time of PCB A side in the heating zone is 2min in total;

[0065] Among them, the reflow furnace includes a heating zone, a reflow soldering zone and a cooling zone in sequence. The starting temperature of the heating zone is 30±1℃ and the final t...

Embodiment 14

[0067] Embodiment 14: A PCB board placement process, which is different from Embodiment 13 in that the residence time of the PCB board A surface in the heating zone is 2.3 min in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com