Preparation method for first cathode layer of solid electrolyte capacitor

A technology of capacitor electrodes and solid electrolysis, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of poor heat resistance, large contact resistance, weak bonding force between carbon layer and contact layer, etc., and achieve reduction Increased contact resistance and heat resistance, suitable for large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

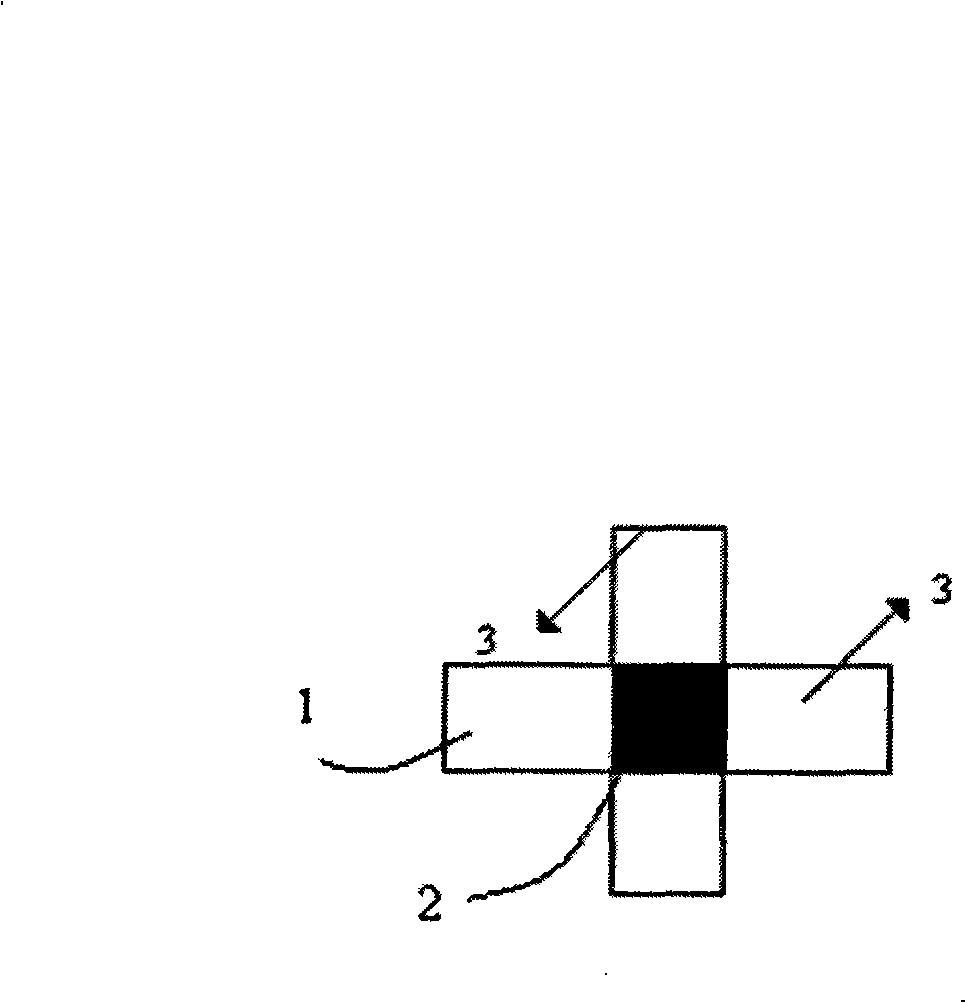

Image

Examples

Embodiment 1

[0020] Raw materials: in parts by mass: 30-40 parts of other resin adhesives; 40-50 parts of viscose solvent; 8% by mass of conductive non-metal.

[0021] The conductive non-metal is a mixture of graphite flakes and carbon powder, the weight ratio of graphite flakes to carbon powder in the mixture is 1:8-8:1, wherein the particle diameter of graphite flakes is ≤10 μm, and the particle diameter of carbon powder is ≤5 μm.

[0022] The resin adhesive is a resin with strong bonding force with the conductive polymer layer and the silver paste layer, and may be one or more of epoxy resin, acrylic resin, polymethyl methacrylate or polyurethane resin.

[0023] The viscous solvent is an organic solvent having the same polarity as the conductive polymer film, and the organic solvent may be one or more of cyclohexanone, butyl acetate or butyl carbitol acetate.

[0024] Mix the raw materials uniformly according to the weight ratio to make graphite milk; cover the electrode that needs to p...

Embodiment 2

[0026] The mass content of conductive non-metal is 15%, and the remaining steps are as in Example 1.

Embodiment 3

[0028] The mass content of conductive non-metal is 30%, and the remaining steps are according to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com