Preparation method of polyamide-based gel polymer electrolyte with multi-network structure

A technology of gel polymer and network structure, which is applied in the direction of solid electrolyte, non-aqueous electrolyte, electrolyte immobilization/gelation, etc. It can solve the problems of poor electrode wettability, reduced ionic conductivity, and deterioration of the interface between positive and negative electrodes. Achieve the effects of strengthening cross-linking degree, high oxidation resistance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] Accurately weigh 0.06 g of N,N-methylenebisacrylamide and dissolve it in an electrolyte system with a ratio of ethylene carbonate to ethyl methyl carbonate of 2:3, and the lithium salt is lithium bistrifluoromethanesulfonylimide (bis The consumption of lithium trifluoromethanesulfonylimide is 0.397g), and the consumption of electrolyte is 1.94g. After stirring for 10min under an argon protective atmosphere, add 0.001g of azobisisobutyronitrile initiator in the mixed solution and continue to stir A gel polymer electrolyte precursor solution is obtained.

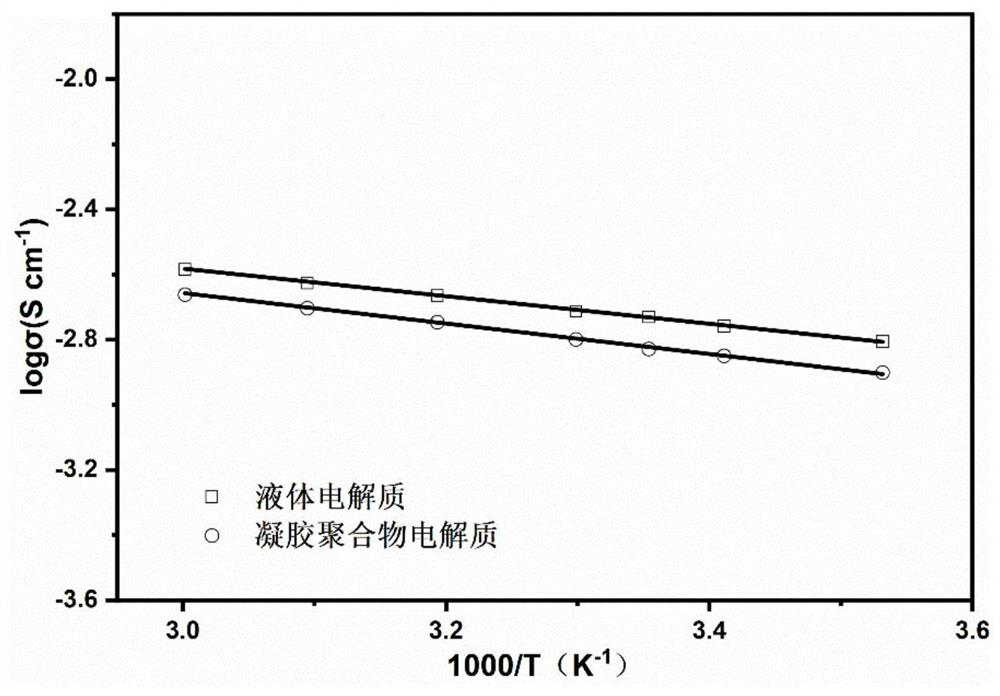

[0031] In a glove box protected by argon and with water and oxygen contents less than 1ppm, the prepared precursor solution was injected into a porous cellulose membrane, and two stainless steel sheets were selected as blocking electrodes to assemble a button battery, and then the battery was placed Heated at 60°C for 4h for in-situ polymerization. Electrochemical workstations were used to perform impedance spectroscop...

Embodiment example 2

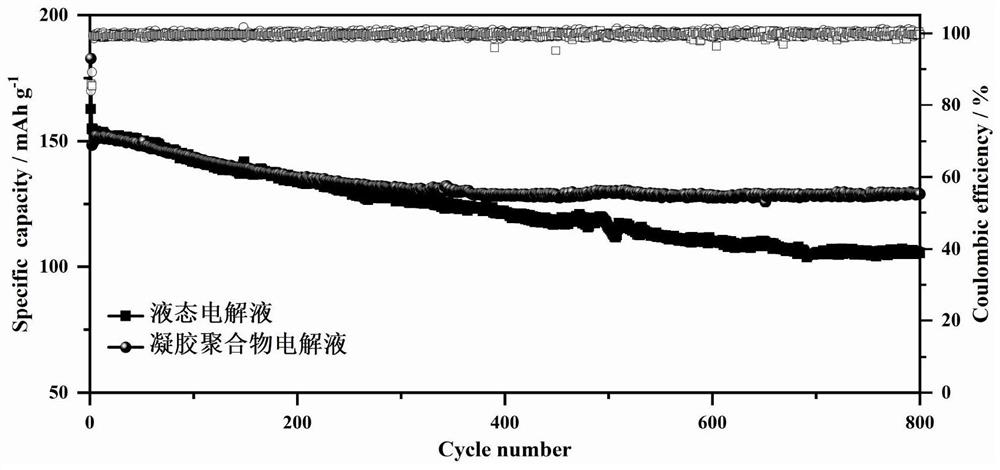

[0033] Choose LiNi 0.6 co 0.2 mn 0.2 o 2 The ternary material is used as the positive electrode, and the lithium sheet is used as the negative electrode. In a glove box protected by argon and with water and oxygen contents less than 1ppm, the precursor solution in Example 1 is injected into the porous cellulose membrane to assemble a ternary material. / lithium metal battery, and then place the battery at 60° C. for 4 h for in-situ polymerization to obtain a gel polymer electrolyte battery. As a comparison, the liquid ternary material / lithium metal battery was assembled with the same organic electrolyte, and the two ternary material / lithium metal batteries assembled above were subjected to a constant current charge and discharge test at a rate of 1C, and the test voltage range was 3.0-4.3V , the measured initial discharge specific capacity of the gel ternary material / lithium metal battery is 155.2mAh / g, which can be cycled stably for 800 cycles, and the capacity retention ra...

Embodiment example 3

[0035] Accurately weigh 0.09 g of N-allyl formamide and dissolve it in an electrolyte system in which the ratio of ethylene carbonate to dimethyl carbonate is 1:1, and the lithium salt is lithium bistrifluoromethanesulfonyl imide (bistrifluoromethane The consumption of lithium sulfonylimide is 0.596g), and the consumption of electrolyte is 2.91g. After stirring for 10min under an argon protective atmosphere, add 0.001g of azobisisobutyronitrile initiator in the mixed solution, and continue to stir to obtain a gel Polymer Electrolyte Precursor Solution.

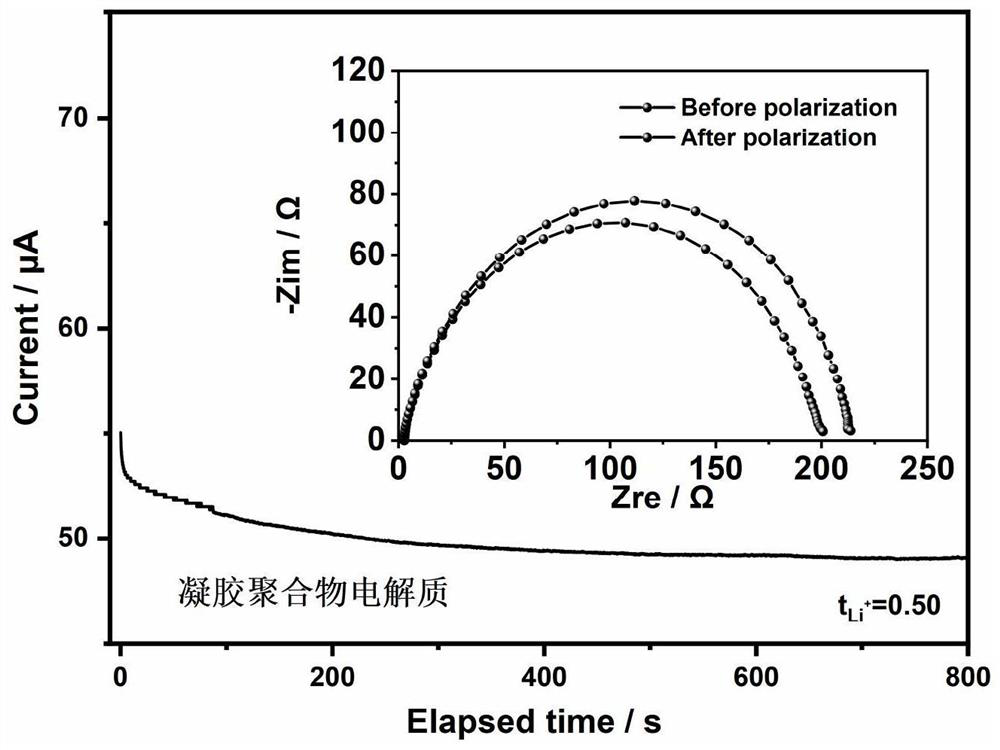

[0036] In a glove box protected by argon and with water content and oxygen content less than 1ppm, inject the prepared precursor solution into a porous cellulose membrane, and select two lithium sheets to assemble a symmetrical battery, and then place the battery at 60°C Heating for 4h in situ polymerization. The electrochemical workstation was used to carry out the steady-state current polarization test and the impedance spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com