Bonding and anchoring combined ceramic thin plate faced wall and mounting method thereof

A technology of ceramic thin plate and installation method, which is applied in the direction of walls, building components, covering/lining, etc., can solve the problems of affecting the curing effect of the adhesive, a large number of metal materials, and high cost, and achieve high bonding integrity and reliability , low cost, easy to obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

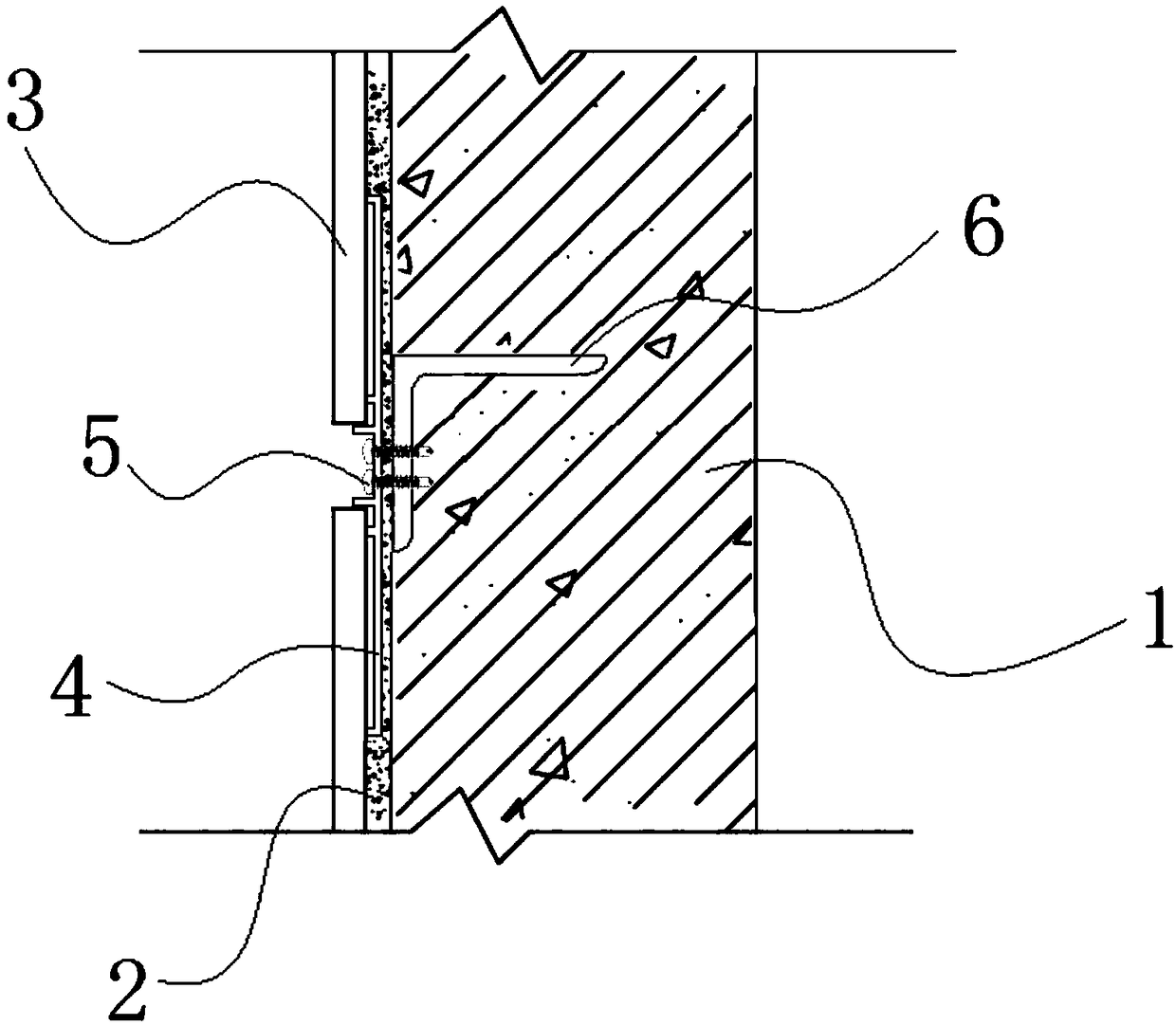

[0034] This embodiment discloses a kind of adhesive anchor bonded ceramic sheet veneer wall body suitable for high-rise buildings with a height exceeding 24 meters, including: a base wall body 1, and an adhesive layer 2 and ceramic tiles arranged on the outside of the base wall body 1 in sequence. Sheet layers.

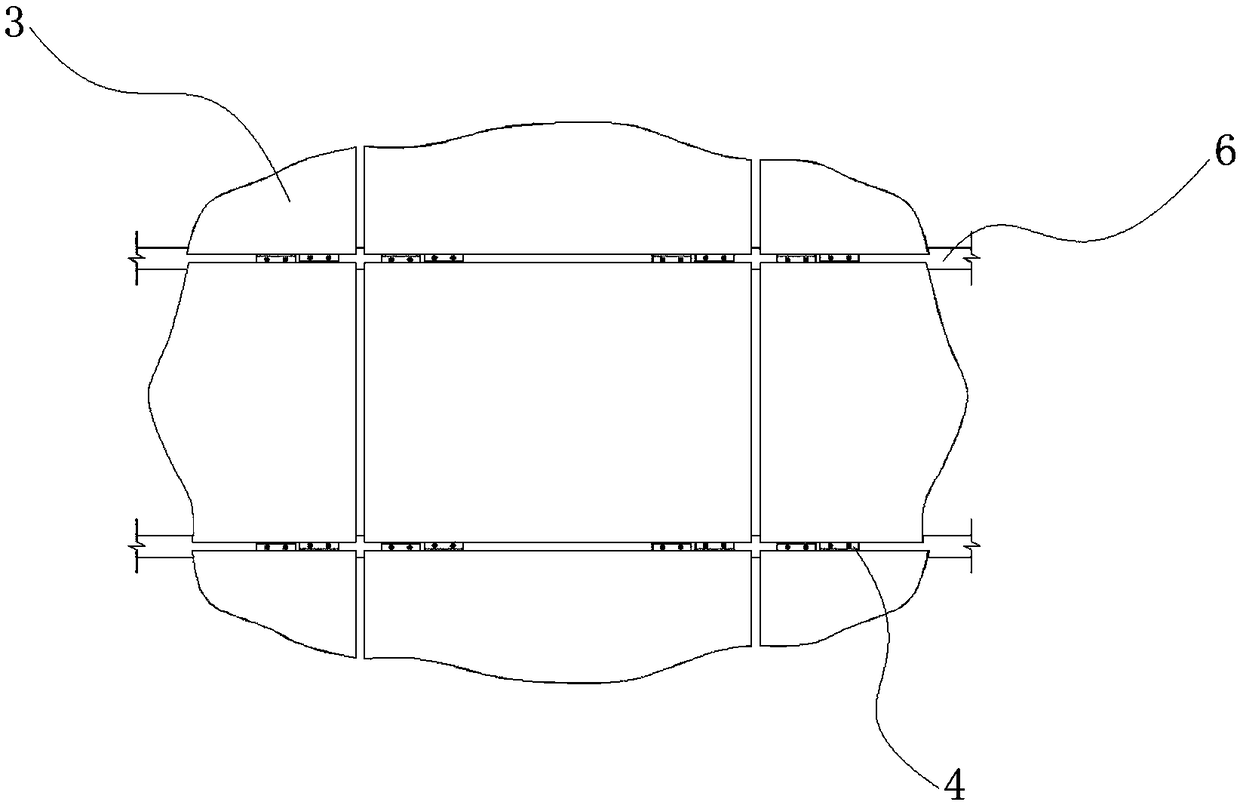

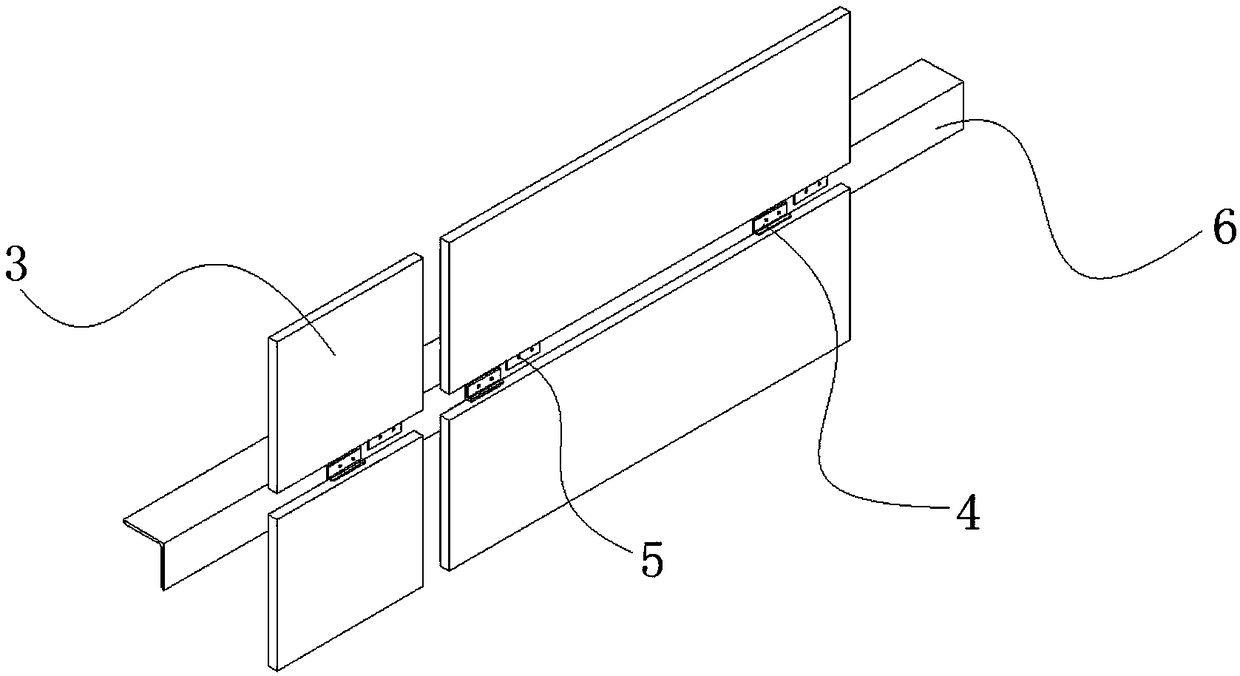

[0035] see figure 1 and figure 2 , two connectors 6 are pre-embedded in the base wall 1. Nine rectangular ceramic thin plates 3 are paved on the outside of the base wall 1 to form a ceramic thin plate layer. Aluminum alloy pendants 4 are fixed on the upper and lower ends of each ceramic thin plate 3 . The back side of the ceramic sheet 3 is scratched with an adhesive layer 2 .

[0036] see Figure 5 , the aluminum alloy hanger 4 includes a mounting plate 401, a bracket clip 402, and a receiving groove 403 containing structural glue. The bracket clip 402 and the receiving slot 403 are arranged on one side of the mounting plate 401 . Two mounting holes 4011 are a...

Embodiment 2

[0041] This embodiment discloses an installation method for bonding anchors combined with ceramic thin plate veneer walls, including the following steps:

[0042] 1) Evenly and fully fill the weather-resistant structural glue into the receiving groove 403 of the aluminum alloy pendant 4 . Wherein, the aluminum alloy hanger 4 includes a mounting plate 401 , a bracket clip 402 and an accommodating groove 403 capable of accommodating structural glue. The bracket clip 402 and the receiving slot 403 are arranged on one side of the mounting plate 401 . Mounting holes 4011 are also arranged on the mounting plate 401 .

[0043] 2) Paste the aluminum alloy pendant 4 on the back corner and / or middle of the pre-cleaned ceramic sheet 3 . Wherein, the elevation of the receiving groove 403 is close to the back of the ceramic thin plate 3 , and is fixedly bonded to the set position on the back of the ceramic thin plate 3 by the structural glue in the receiving groove 403 . The bracket cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com