Fiber-reinforced resin composite material hollow ball and preparation method thereof

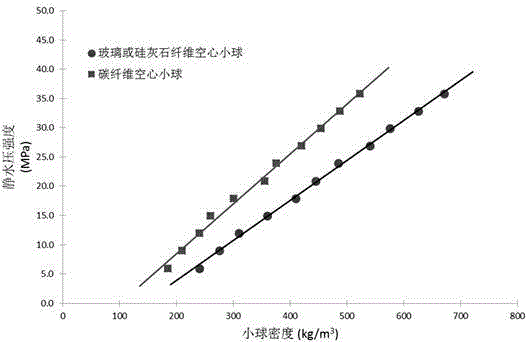

A fiber-reinforced resin and composite material technology, which is applied in the field of fiber-reinforced resin composite hollow spheres and its preparation, can solve the problems of unsatisfactory density and specific strength, and achieve the effects of simple preparation process, low speed and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of fiber-reinforced resin composite hollow spheres

[0026] With 1 cubic meter of steam-expanded and foamed polystyrene balls as the spherical core, the weight of each layer of liquid epoxy resin is 2KG, TETA is 0.4KG, and carbon fiber is 3KG. The preparation process is as follows:

[0027] Raise the temperature of the roller with an inclination angle of 15° to the ground to 35°C, transfer the steam-expanded and foamed polystyrene pellets into the roller, and control the speed at 100rpm, and then mix the pre-mixed liquid epoxy resin with TETA Put the mixed solution into the drum and evenly coat the surface of polystyrene pellets. After 1 minute, add carbon fiber to make it evenly adhere to the surface of the pellets, and cure at 35° for 45 minutes; repeat this coating step several times, each curing After 3-5 layers, take it out and measure its density until the measured polystyrene pellets have a target density of 100–600kg / m 3 Within the scope,...

Embodiment 2

[0028] Example 2: Preparation of fiber-reinforced resin composite hollow spheres

[0029] With 1 cubic meter of steam-expanded and foamed polystyrene balls as the spherical core, the weight of each layer of liquid epoxy resin is 5KG, TEPA is 0.5KG, and wollastonite fiber is 5KG. The preparation process is as follows:

[0030] The temperature of the roller with an inclination angle of 30° to the ground is raised to 70°C, and the steam-expanded and foamed polystyrene pellets are transported into the roller, and the speed is controlled at 10rpm, and then the pre-mixed liquid epoxy resin and TEPA Put the mixed solution into the drum and evenly coat the surface of the polystyrene pellets. After 5 minutes, add wollastonite fiber to make it evenly adhere to the surface of the pellets. Curing at 70° for 15 minutes; repeat this coating step several times After every 3-5 layers of solidification, take it out and measure its density until the measured polystyrene pellets are in the targe...

Embodiment 3

[0031] Example 3: Preparation of hollow spheres of fiber-reinforced resin composites

[0032] With 1 cubic meter of steam-expanded and foamed polystyrene balls as the spherical core, the weight of each layer of liquid epoxy resin is 3KG, the IPD is 0.5KG, and the glass fiber is 8KG. The preparation process is as follows:

[0033] Raise the temperature of the roller with an inclination angle of 25° to the ground to 40°C, transfer the steam-expanded and foamed polystyrene pellets into the roller, and control the speed at 10rpm, and then mix the pre-mixed liquid epoxy resin with IPD Add the mixed solution into the drum and evenly coat the surface of the polystyrene pellets. After 3 minutes, add glass fiber to make it evenly adhere to the surface of the pellets, and cure at 40° for 30 minutes; repeat this coating step several times, each After curing 3-5 layers, take it out and measure its density until the measured polystyrene pellets have a target density of 100–600kg / m 3 Withi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com