Pre-mixed antimicrobial, fast-curing, and collapse-resistant calcium silicate-based bioactive materials

A bioactive, fast curing technology, applied in the field of biomedical materials, can solve the problems of increasing extra treatment time, uneven physical and chemical properties, affecting the patient's medical experience, etc., to improve the efficacy of root canal treatment, shorten the curing time, and achieve excellent flow Effects of sexual and injectable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First weigh 1.8g of tricalcium silicate powder and 0.2g of disodium hydrogen phosphate, mix evenly, then select polyethylene glycol as the non-aqueous phase carrier, weigh 1.2g and mechanically stir with the above solid phase powder, A premixed paste is formed, which is then stored in a syringe.

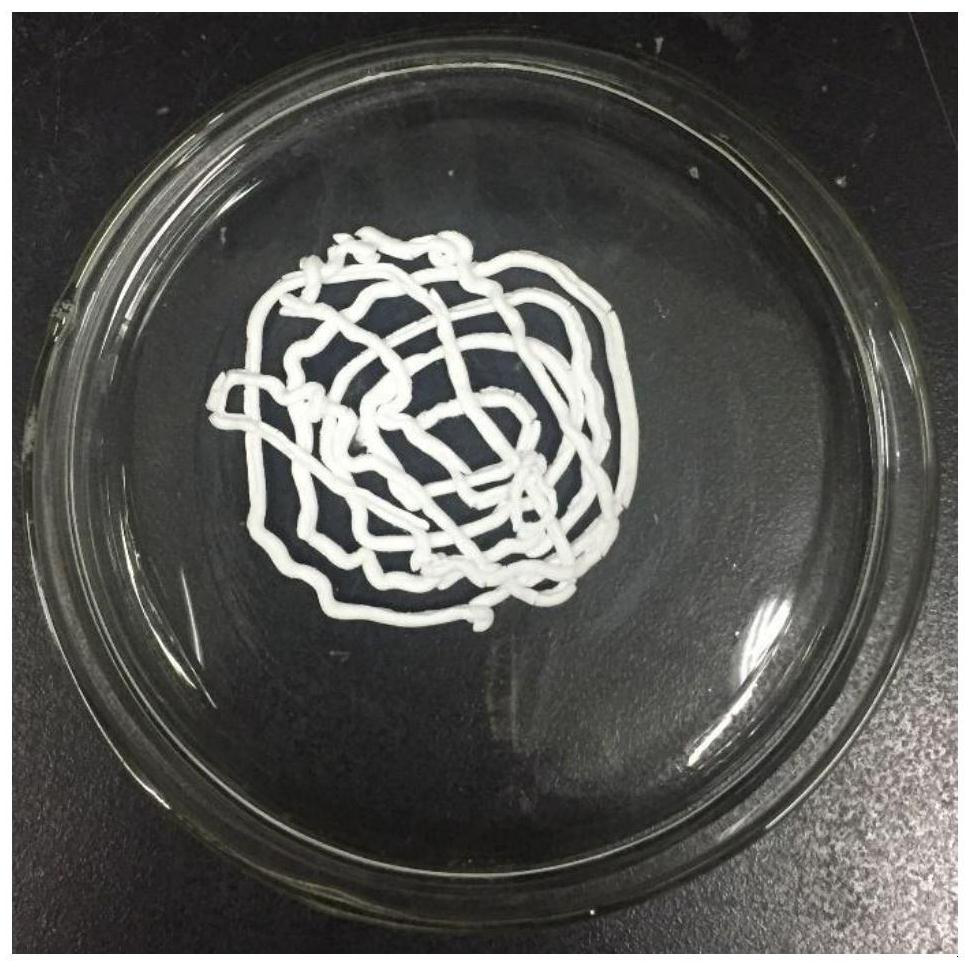

[0042] Inject the prepared premixed paste into the simulated body fluid, and observe whether the pasty slurry collapses. The results are as follows: figure 1 As shown, the pasty slurry can maintain its original shape after soaking in the liquid phase for 30 minutes.

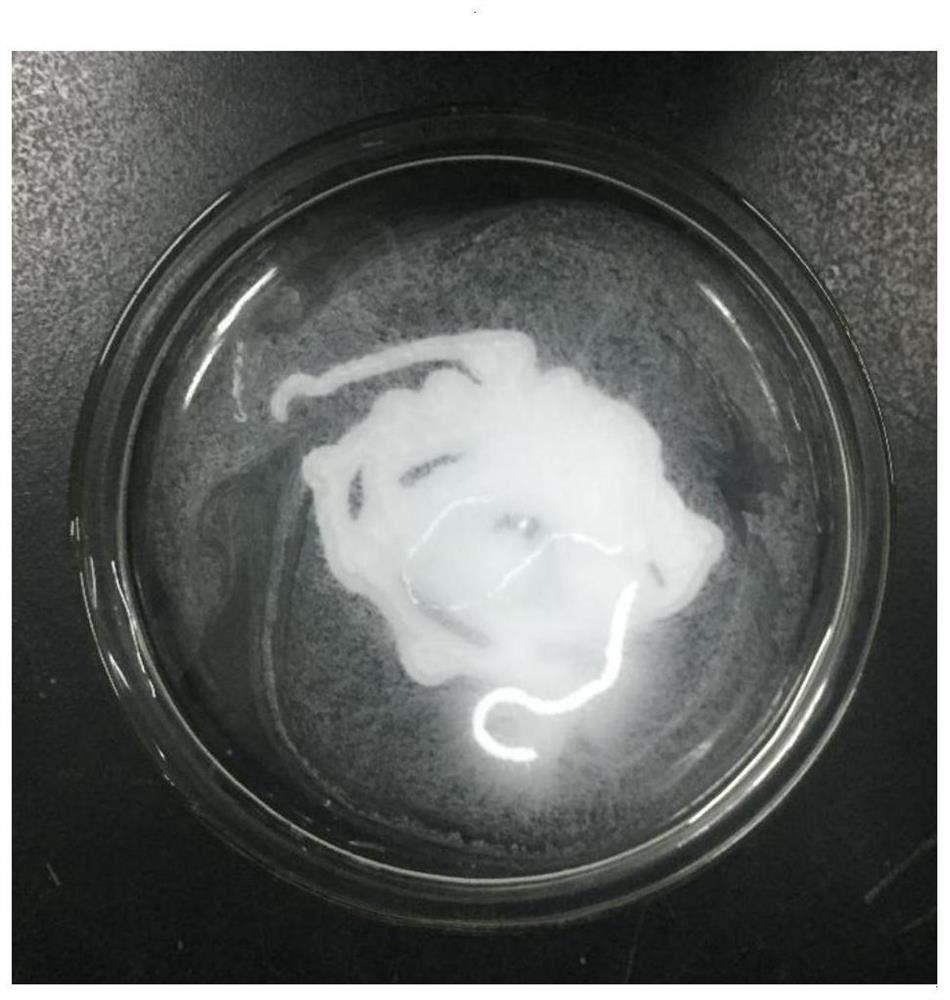

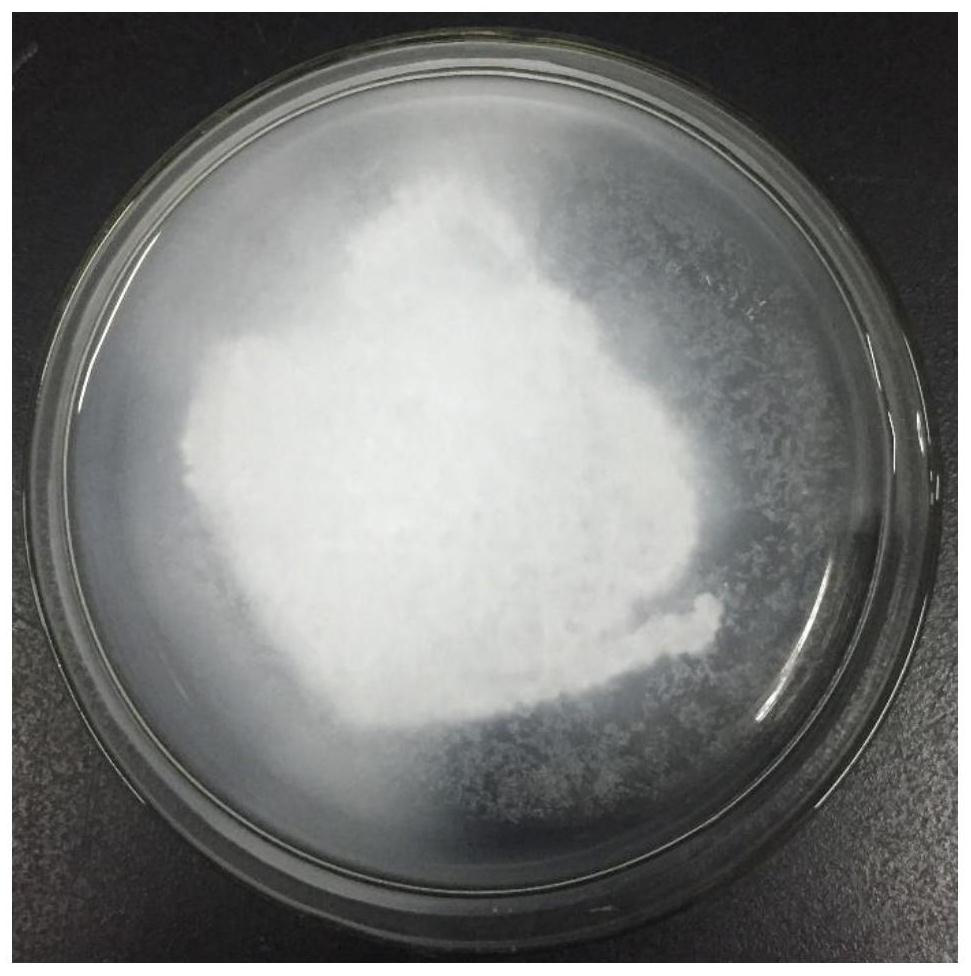

[0043] As a comparison, Example 1 is also used as a basic example in the present invention. Under other conditions being the same, under the condition of not adding disodium hydrogen phosphate, the prepared calcium silicate-based bioactive material is soaked in liquid phase respectively. Characterize the collapse performance after soaking the liquid phase for 30 minutes; figure 2 and image 3 Respectively, a ...

Embodiment 2

[0045] First weigh 2.16g of tricalcium silicate powder, 0.24g of disodium hydrogen phosphate and 0.6g of zirconia powder, mix them uniformly, then select polyethylene glycol as the non-aqueous phase carrier, weigh 1.8g and mix with the above solid The phase powder is mechanically stirred to form a premixed paste, and then the paste is put into a syringe for storage.

[0046] The X-ray opacity performance of the premixed paste was measured with an X-ray machine, and the results are shown in Table 1. The premixed paste has a radiopaque performance equivalent to a thickness of 3.04mm aluminum plate, which is higher than the clinical requirement of 3mm for dental filling materials. The anti-radiation performance of the thickness of the aluminum plate has sufficient X-ray anti-radiation performance, which can meet the requirements of clinical applications. After preliminarily curing the above-mentioned premixed slurry, the tooth body was soaked in simulated body fluid for 7 days, a...

Embodiment 3

[0050] First weigh 1.2g of tricalcium silicate powder and 0.8g of disodium hydrogen phosphate, mix evenly, then select polyethylene glycol as the non-aqueous phase carrier, weigh 1.2g and mechanically stir with the above solid phase powder, A premixed paste was formed, poured into molds and cured at 37°C.

[0051]The curing time of the premixed paste was measured by a penetrometer. The results are shown in Table 2. Compared with the premixed slurry without disodium hydrogen phosphate, the curing time of the composite slurry was reduced from 10.95 hours to 3.7 hours. Hours, the results show that the addition of disodium hydrogen phosphate can significantly reduce the curing time of the premixed paste, which is beneficial to promote the hydration reaction of calcium silicate-based gelling materials.

[0052] Table 2 curing time test results

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com