Hollow-microsphere-filled epoxy resin composite foam material and preparation method thereof

A technology of epoxy resin and composite foam, which is applied in the field of foam materials, can solve the problems of not being able to meet the requirements of light weight, unsatisfactory mechanical properties, and decreased mechanical properties, and achieve the effects of uniform distribution, low cost, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

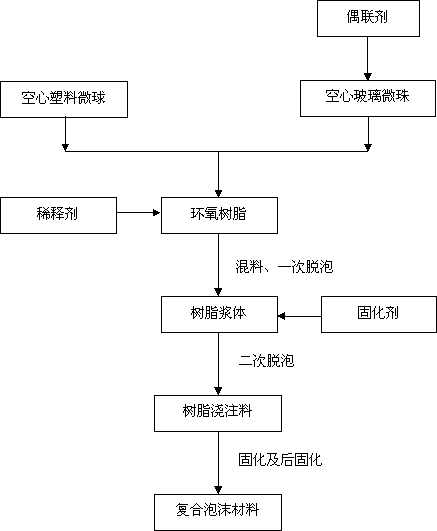

[0026] Such as figure 1 As shown, a method for preparing hollow microsphere-filled epoxy resin composite foam material includes the following steps:

[0027] 1) Modification of hollow glass beads:

[0028] a. First add a small amount of ethanol to a certain amount of water, and adjust the pH of the solution with glacial acetic acid to make pH=5.0. Then, while stirring, add the coupling agent KH550 dropwise to the solution, adjust the concentration of the coupling agent to 0.5 wt%, and continue to stir for 1.0 h to completely hydrolyze the coupling agent;

[0029] b. Adjust the hydrolyzed coupling agent solution to pH=5.5, add a certain amount of hollow glass beads K46 to it, and then heat the solution in a water bath at 60 ℃ and stir at low speed for 30 minutes. After the reaction, filter with suction and use beads Rinse the beads 3 times with 400 wt% distilled water, and finally dry them in an oven at 100 ℃ to a constant weight;

[0030] 2) Mixing and one-time deaeration: select the...

Embodiment 2

[0043] 1) Modification of hollow glass beads:

[0044] a. First add a small amount of ethanol to a certain amount of water, and adjust the pH of the solution with glacial acetic acid to make pH=6.0. Then, while stirring, add the coupling agent KH570 dropwise to the solution, adjust the concentration of the coupling agent to 0.1 wt%, and continue to stir for 1.5 h to make the coupling agent completely hydrolyzed;

[0045] b. Adjust the hydrolyzed coupling agent solution to pH=5.0, add a certain amount of hollow glass beads K46 to it, and then heat the solution in a water bath at 70 ℃ and stir at low speed for 60 min. After the reaction, filter with suction and use beads Rinse the beads 3 times with 400 wt% distilled water, and finally dry them in an oven at 100 ℃ to a constant weight;

[0046] 2) Mixing and one-time degassing: select hollow polystyrene microspheres with epoxy resin weight of 1.5 wt%, modified hollow glass beads with epoxy resin weight of 30 wt%, and add the above raw...

Embodiment 3

[0050] 1) Modification of hollow glass beads:

[0051] a. First add a small amount of ethanol to a certain amount of water, and adjust the pH of the solution with glacial acetic acid to make pH=4.0. Then, while stirring, add the coupling agent KH560 dropwise to the solution, adjust the concentration of the coupling agent to 1.0 wt%, and continue stirring for 2 h to make the coupling agent completely hydrolyzed;

[0052] b. Adjust the hydrolyzed coupling agent solution to pH=6.5, add a certain amount of hollow glass beads K46 to it, and then heat the solution in a water bath at 50 ℃ and stir at low speed for 50 min. After the reaction, filter with suction and use beads Rinse the beads twice with 400 wt% distilled water, and finally dry them in an oven at a temperature of 50 ℃ to a constant weight;

[0053] 2) Mixing and one-time deaeration: select the reactive diluent XY678 with 10 wt% epoxy resin weight, hollow polystyrene microspheres with 6.0 wt% epoxy resin weight, and modified h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com