Aerogel based composites

A composite material and aerogel technology, applied in the field of composite foam materials and composite materials, can solve problems such as application limitations of composite foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] Nanogel Airgel particles / PVA slurries were mixed with 10 micron size Nanogel Granules (150 g) were prepared by adding to 1.5 liters of a solution containing 150 g of PVA and 20.5 g of Barlox 12i (100% basis). After shaking and stirring, a slurry with a milky consistency was formed. The slurry was laboratory dried at 100 °C to obtain a layered structure with an upper blocky layer rich in PVA, , representing the bulk of the material, an intermediate powdery layer and a bottom layer rich in PVA. The upper block was floated in isopropanol. Thermogravimetric studies indicated that the sample contained 42 wt% Nanogel Granules (ie, PVA:Nanogel weight ratio is about 1.4:1). The blocks were mixed into the epoxy resin at 40 and 50 volume % loading (assuming the blocks had a density of 0.27 g / cc) resulting in composites which appeared to be non-porous. Epoxy resin containing 40% by volume blocks was floated in isopropanol. An epoxy resin comprising 50 volume v% blocks was ...

Embodiment 2

[0182] Nanogel Water-Based Epoxy Composites: Water-based epoxy emulsions / dispersions are used with aqueous curing agents. Epoxy emulsions / dispersions are stabilized with surfactants. The hydrophobic nature of the Nanogel particles prevents the ingress of solutions. Gently agitate the 1-pot mixture of water-based epoxy (WBE), aqueous curing agent, and Nanogel granules. Excess surfactant in WBE helps to wet the Nanogel particles and get compact nanogel-epoxy composites. Nanogel grades TLD302, TLD101, 08N, in sizes 3.0, 1.0, and 0.08mm, respectively, were used. The composite was dried overnight, followed by curing at 70°C for 12 hours and resulted in a lightweight composite with favorable thermal properties.

[0183] Typical composition used: (i) sample SF_08N: 16g EPI REZ 3515, 4g EPI KURE8535, 3g Nanogel 08N (ii) sample SF_101: 16g EPI REZ 3515, 4g EPI KURE 8535, 6g water, 4g Nanogel TLD101. EPI REZ and EPI KURE chemicals were obtained from Resolution Performance Products. ...

Embodiment 3

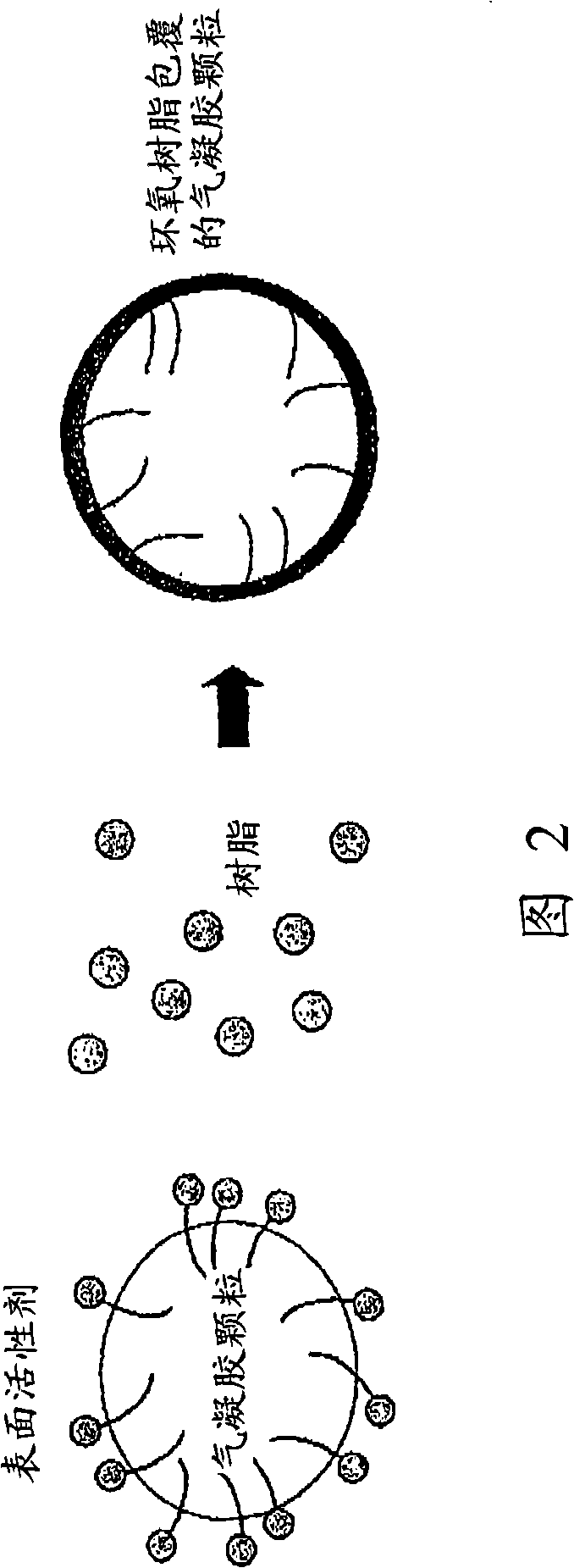

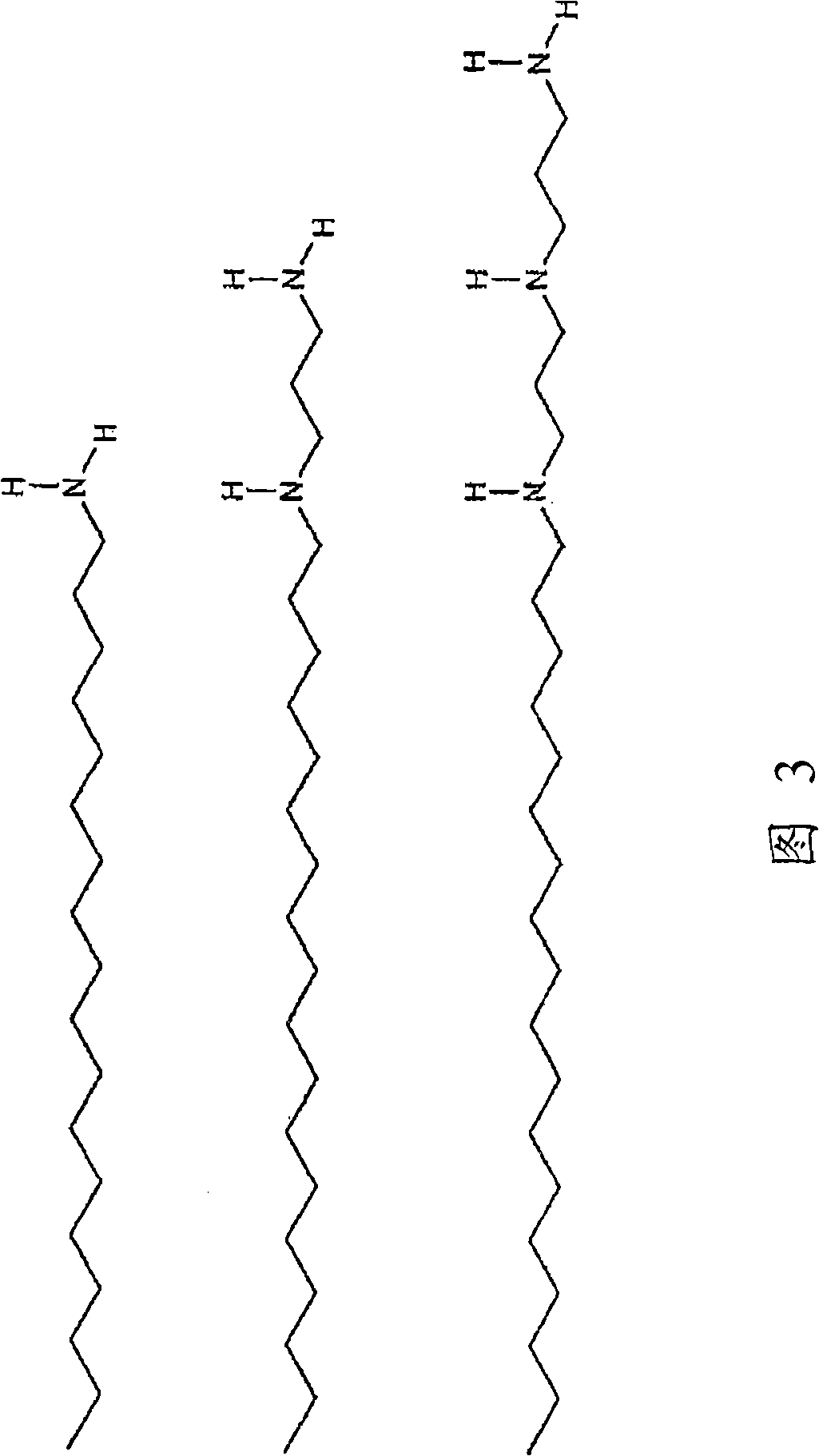

[0187] Nanogel particles coated with water-based epoxy resin: Unlike Example 2 above where the curing agent was mixed into the aqueous mixture, a surface-active curing agent was used to modify the surface of the Nanogel particles to obtain a thin coating of epoxy resin formed on the Nanogel particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com