Production method of hollow ball metal composite foamed material

A metal composite and foam material technology, applied in the field of foam metal materials, can solve the problems of low production efficiency of preparation technology, high equipment requirements, inability to meet the production requirements of light weight, high strength and large-sized special-shaped structural parts, etc. The effect is remarkable, the overall density is low, and the light weight is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

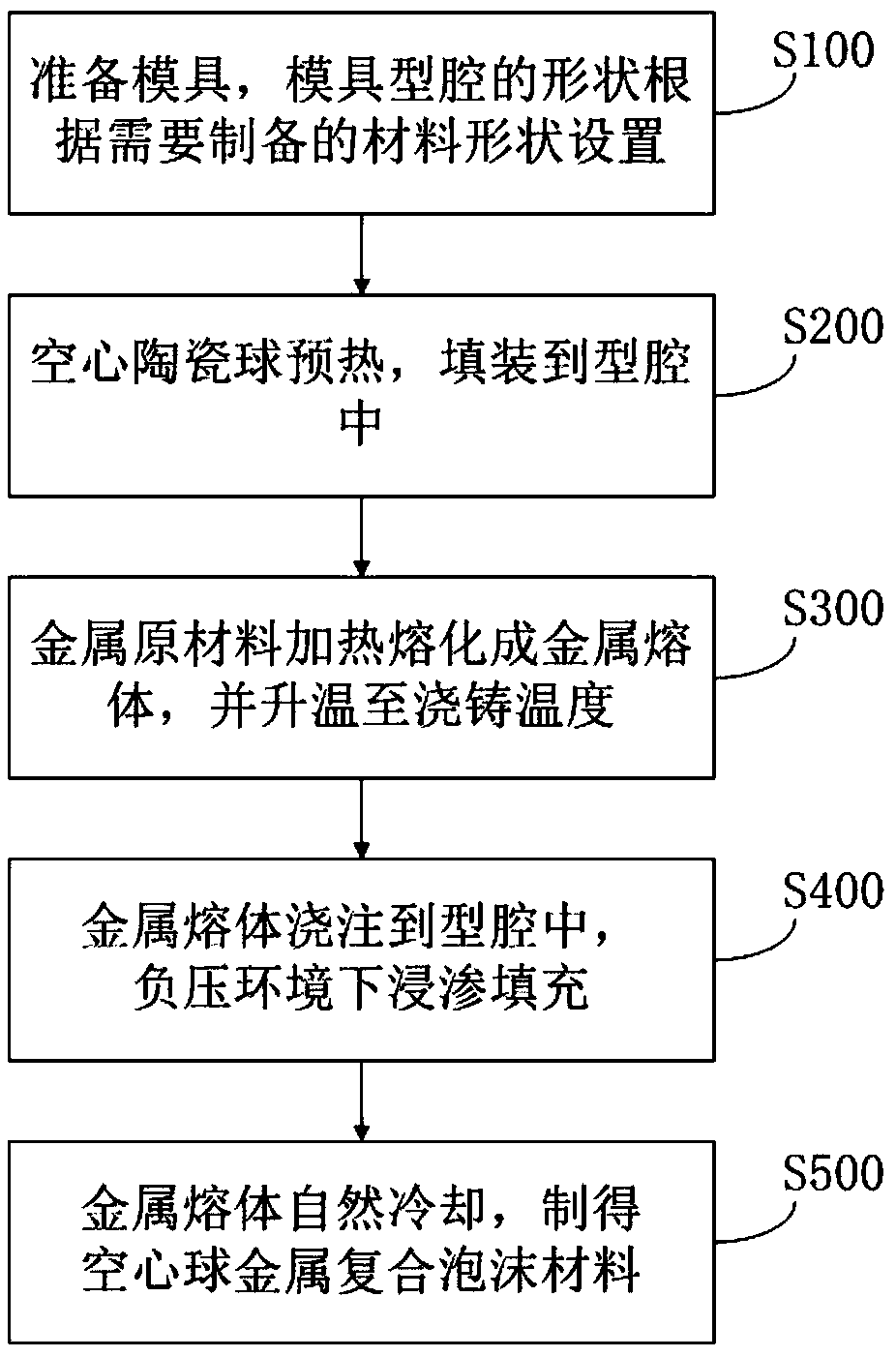

[0038] This embodiment provides a method for producing a hollow spherical metal composite foam material. Through the casting process, the special-shaped structure of the porous structure composite material is integrally formed at one time, such as figure 1 As shown, the method includes the following steps:

[0039] S100: Prepare a mold, the mold is provided with a cavity for material molding, and the shape and size of the cavity can be adjusted according to the needs of the finished structure.

[0040] S200: Select hollow ceramic balls. Ceramic hollow balls can choose alumina, boron carbide, boron nitride, silicon nitride, aluminum nitride, and zirconia ceramics. The particle size of ceramic hollow balls is 2mm to 8mm. Preheat the hollow ceramic balls. After filling into the cavity, you can use hollow ceramic balls of the same particle size, or you can choose hollow ceramic balls with different particle sizes. The hollow ceramic balls with small particle sizes will fill the ga...

Embodiment 2

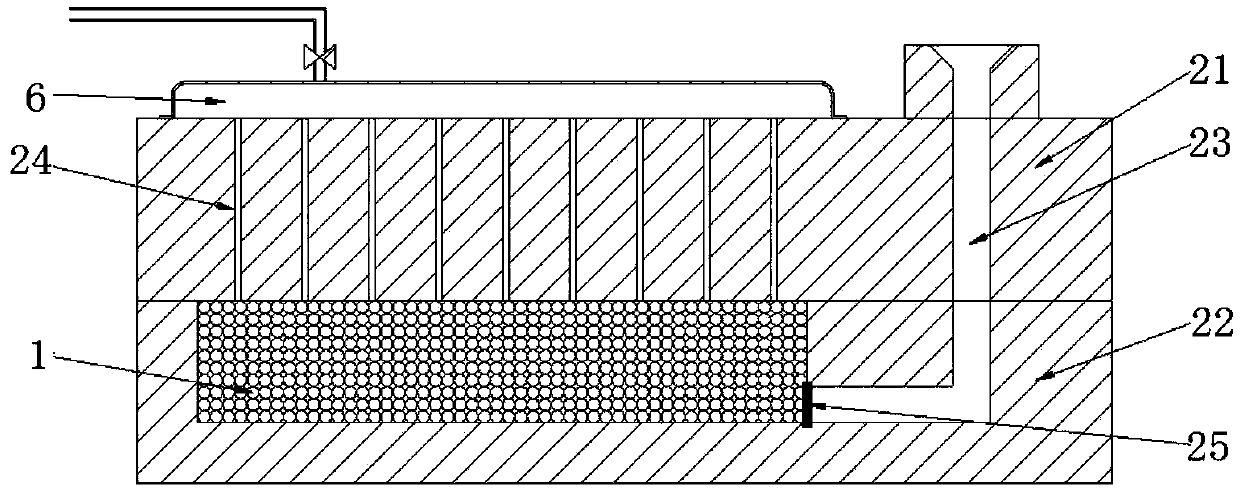

[0046] Such as figure 1 and figure 2 Shown, a kind of sand casting molding preparation method of hollow spherical metal composite foam material, comprises the following steps:

[0047] S100: Prepare a mold. The mold in this implementation is a sand mold, including an upper sand mold 21 and a lower sand mold 22. The upper sand mold 21 can be opened and removed. The lower sand mold 22 is provided with a cavity for forming structural parts, and the shape and size of the cavity can be adjusted according to the needs of the finished structural parts. The sand mold is provided with a sand runner 23, which communicates with the bottom of the mold cavity, and a sand filter 25 is set at the connecting part of the sand runner 23 and the mold cavity to prevent impurities in the prepared material. The upper sand mold 21 is provided with ventilation holes 24 communicating with the mold cavity. The diameter of the ventilation holes 24 is 1 mm to 3 mm. The distribution and quantity of the...

Embodiment 3

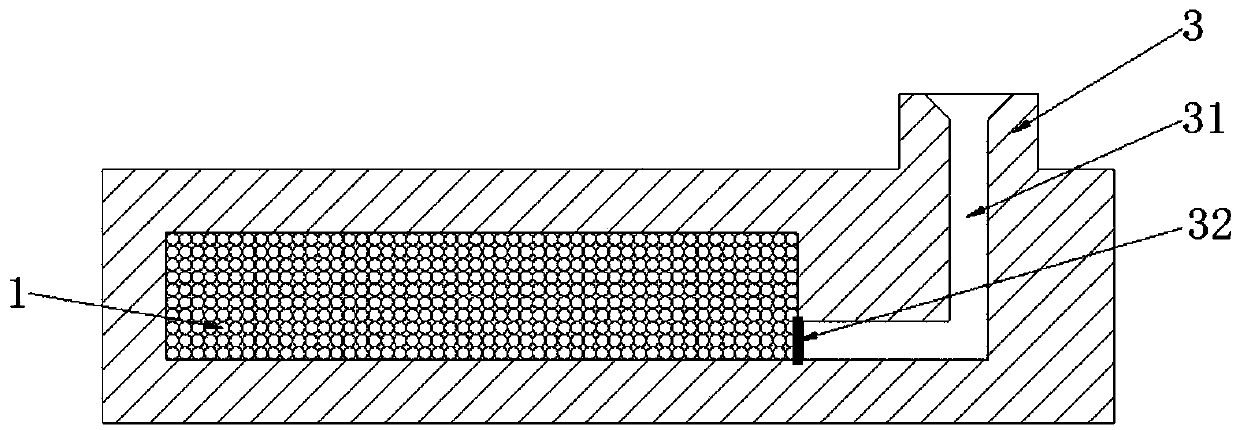

[0054] Such as figure 1 and image 3 Shown, a kind of metal type gravity casting molding preparation method of hollow spherical metal composite foam material, comprises the following steps:

[0055] S100: Prepare the mold. The mold in this implementation is a split-type first metal mold 3, including a left metal mold and a right metal mold. The first metal mold 3 can be opened left and right. The shape and size of the cavity can be adjusted according to the needs of the finished structural parts. The first metal mold 3 is provided with a metal mold runner 31, and the metal mold runner 31 communicates with the bottom of the mold cavity, and a metal mold filter screen 32 is set at the communication part between the metal mold runner 31 and the mold cavity, so as to prevent the prepared material from hollow ceramics. The ball overflows into the sprue. The parting surface between the left metal type and the right metal type has an exhaust gap, which is used to discharge the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com