Blended yarn and preparation method and application thereof

A technology of blending yarns and rovings, which is applied in the directions of textiles, papermaking, and yarns, can solve the problems of small cohesion, limited application fields, and difficulty in preparing high-quality high-count yarns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The pretreatment of embodiment 1 milk fiber 1#

[0078] The raw milk fiber is pretreated for health preservation. 100Kg of milk fiber is mixed with 2.5Kg of antistatic agent aqueous solution. The weight ratio of antistatic agent to water is 1:15. Wrap the bag and seal it and let it stand for more than 24 hours. The temperature in the health care room is controlled at 45°C-55°C, so that the antistatic agent solution can be evenly diffused into the fiber under the action of high temperature. The antistatic agent is a silicone surface active antistatic agent. Get milk fiber 1#.

Embodiment 2

[0079] Embodiment 2 milk fiber 2#-3#, contrast the pretreatment of milk fiber D1#-D2#

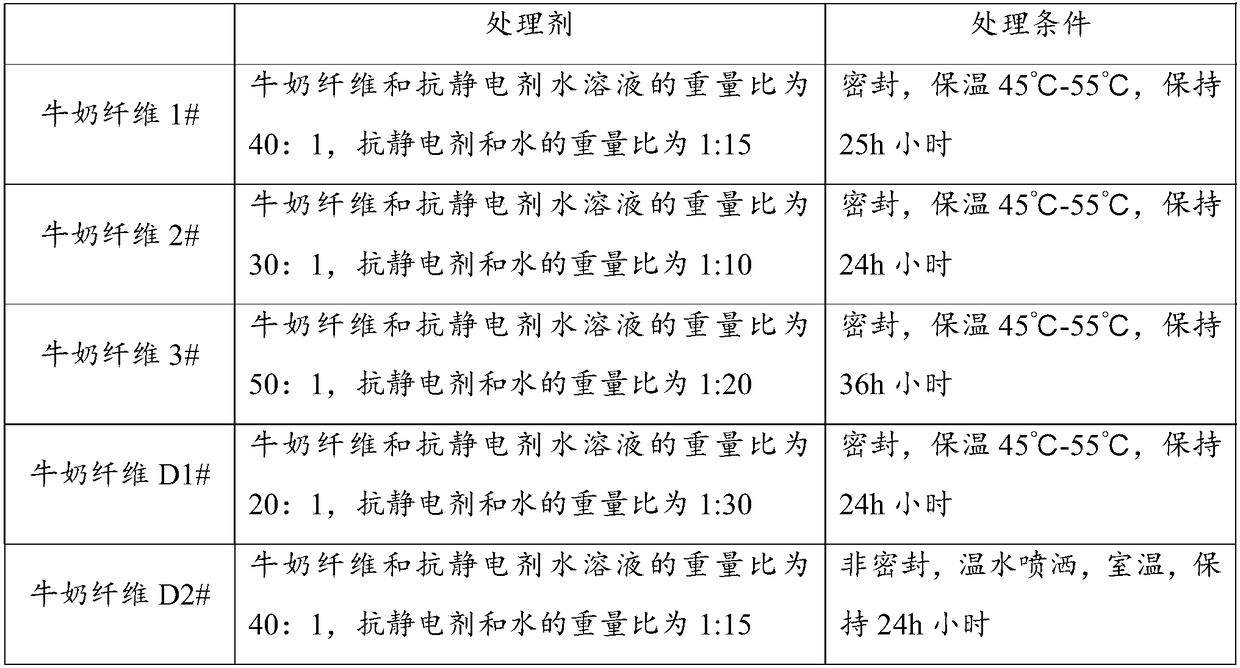

[0080] The raw milk fiber was pretreated with a pretreatment method different from that of milk fiber 1#, and milk fiber 2#, milk fiber 3#, comparison milk fiber D1#, and comparison milk fiber D2# were prepared respectively, which were compared with milk fiber 1# The differences in the preprocessing methods are shown in Table 1.

[0081] Table 1

[0082]

Embodiment 3

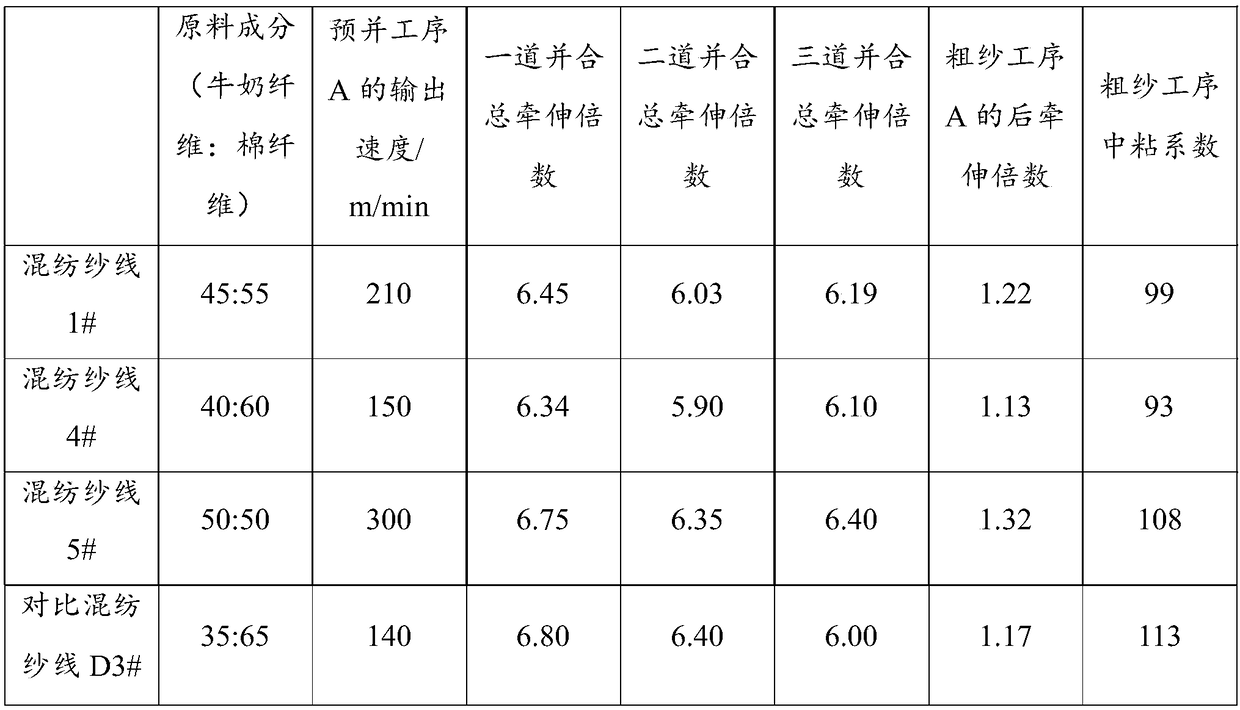

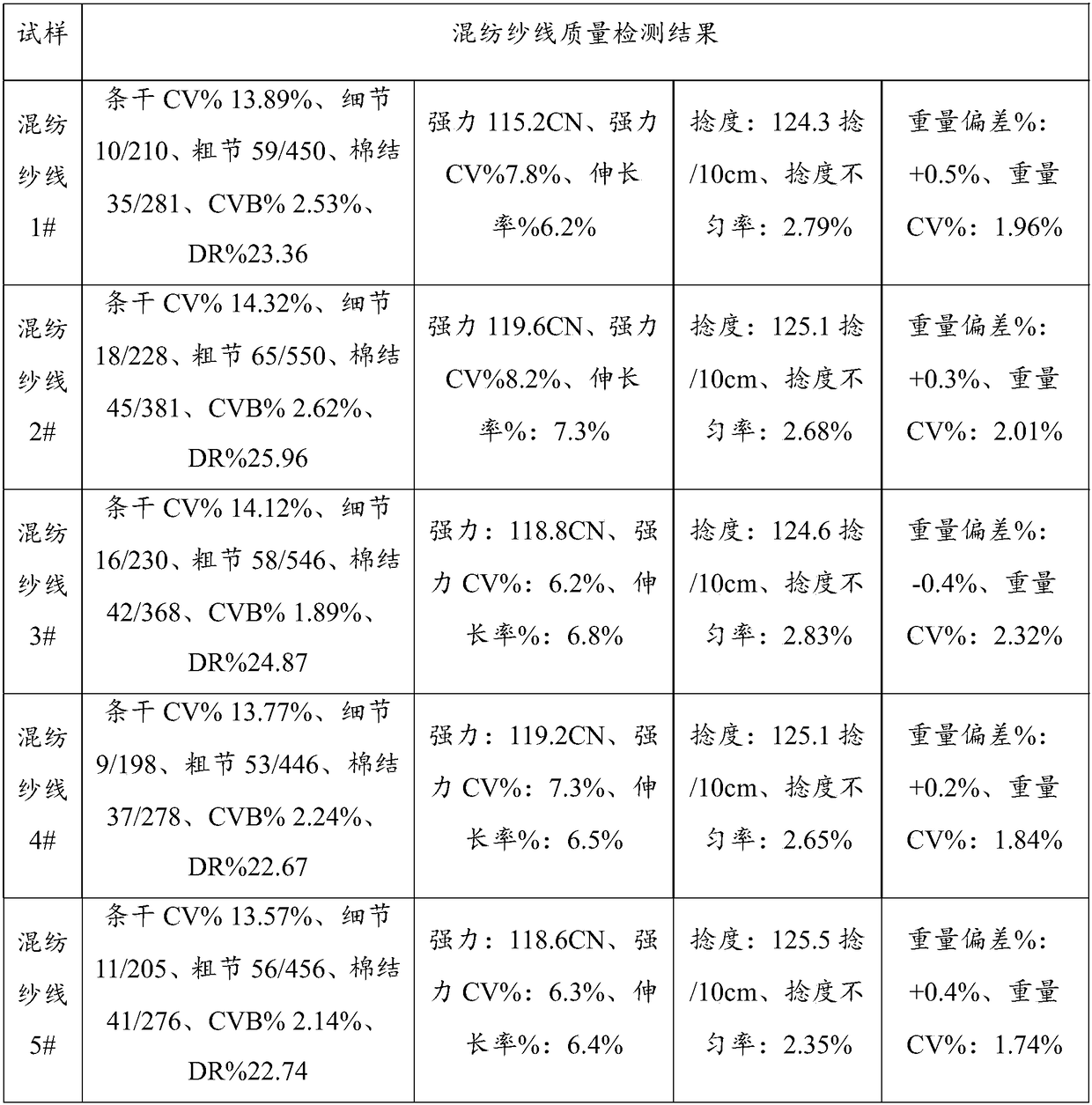

[0083] Preparation of embodiment 3 blended yarn 1#-3#, contrast blended yarn D1#-D2#

[0084] Milk fiber 1#, milk fiber 2#, milk fiber 3#, contrast milk fiber D1#, contrast milk fiber D2# prepared in embodiment 1 and embodiment 2 are prepared blended yarns according to the same method, and blended yarns are prepared respectively Yarn 1#, blended yarn 2#, blended yarn 3#, contrast blended yarn D1#, contrast blended yarn D2#. Taking milk fiber 1# and cotton fiber to prepare blended yarn 1# as an example to illustrate the preparation method of blended yarn.

[0085]The raw material of blended yarn 1#: the weight ratio of milk fiber 1# and cotton fiber is 45:55.

[0086] The preparation method of blended yarn 1#, comprises the steps:

[0087] 1) Process the pretreated milk fiber 1# through cleaning process A, carding process A and pre-combining process A in sequence;

[0088] Cleaning process A: The weight of milk fiber 1# is 12.90kg, and the roll length is 30m; after being pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com