Production method for all-cotton spunlace non-woven fabric for medical health

A spunlace non-woven, medical and hygienic technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of no impurity and neps removal, difficulty in degreasing and bleaching, high water and heat consumption, etc., to improve cleanliness The effect of reducing the defect rate of products, saving raw materials and energy

Active Publication Date: 2015-11-25

湖北欣柔卫生用品股份有限公司

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

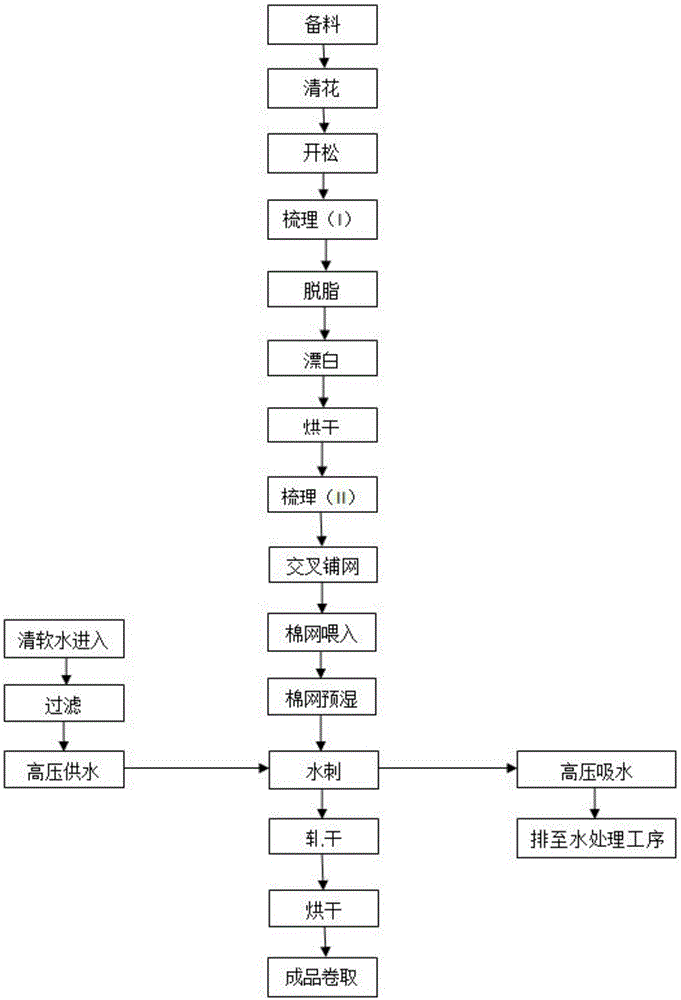

The production process is: flower cleaning → combing → web laying → spunlace → degreasing → bleaching → drying → finished product coiling. The defect of this production method is that the process is complicated. 2-3 times of bleaching, low production efficiency, large water and heat consumption, high production cost

Moreover, there

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

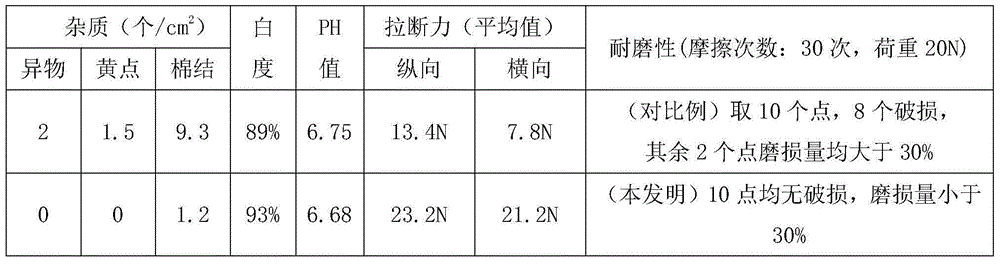

The invention discloses a production method for all-cotton spunlace non-woven fabric for medical health. The production method includes the steps that blowing is conducted, wherein dust removing is conducted on pure-natural ginned cotton; primary carding is conducted, wherein fibers are combed to be orderly arranged, and impurities in raw materials are further removed; degreasing is conducted, wherein wax or grease on the cotton fibers is removed; bleaching is conducted; secondary carding is conducted, wherein the fibers are combed to be orderly arranged, and cotton knots may be generated in degreasing and bleaching are removed; net laying is conducted, wherein carded cotton nets are overlapped and spread in a reciprocating and staggered mode in the direction of the cotton fibers of the cotton nets; spunlacing is conducted, wherein high-pressure water flow is used for tangling the cotton nets; finished products are coiled. The two times of carding is conducted, greasing is conducted, then spunlacing is conducted, so that impurities and cotton knots are reduced to the maximum, the production cost is reduced, and raw materials and energy are saved. According to the production method, the raw material of the direct product is the pure-natural cotton so that the fabric is soft in texture, good in affinity with the skin, free of toxins, irritation and sensitization, good in water absorption, convenient to use and comfortable.

Description

technical field [0001] The invention belongs to the technical field of textiles, and in particular relates to a method for producing a cotton spunlace nonwoven fabric for medical and sanitary use. Background technique [0002] Medical materials mainly include synthetic fiber non-woven fabrics and cotton non-woven fabrics. The composition of synthetic fiber non-woven fabrics is generally 70% viscose, 30% polyester (including petroleum synthetic raw materials), and its raw material resources are non-renewable. High, the cost of destruction after use is high, and it is not environmentally friendly. At the same time, some users will be allergic to its materials during use, so synthetic fiber non-woven medical materials are not widely used. The cotton spunlace non-woven fabrics for medical and health use are natural cotton, the raw materials are sufficient, and the treatment is simple, and the cotton spunlace non-woven fabrics for medical and hygiene are soft, environmentally fri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D04H1/425D04H1/492D04H1/70

Inventor 江雷

Owner 湖北欣柔卫生用品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com