Movable cover board carding device for cotton carding machine

A technology of movable cover and carding machine, which is applied in deburring devices, fiber processing, textiles and papermaking, etc., and can solve problems such as increasing costs and increasing the difficulty of processing large curved tracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

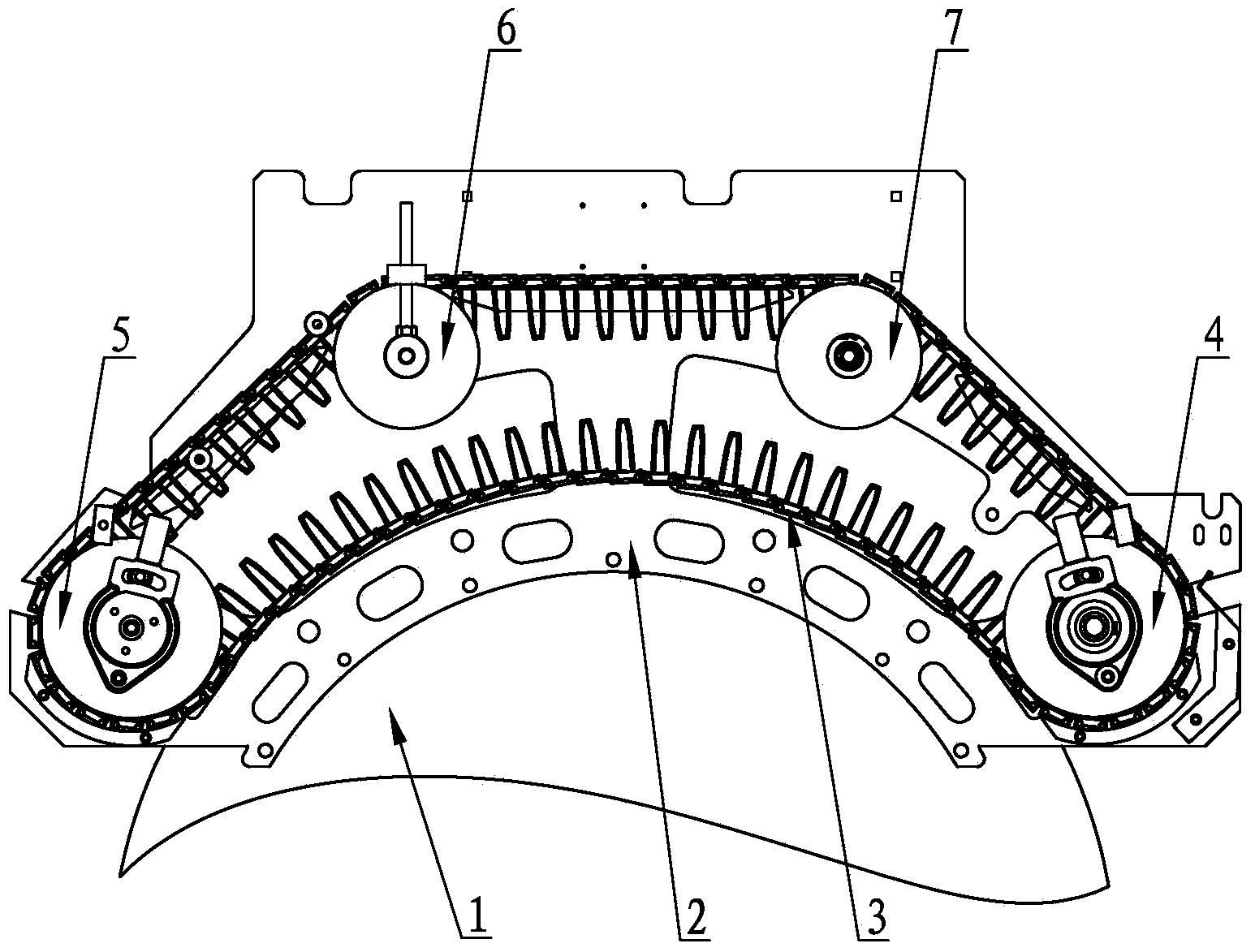

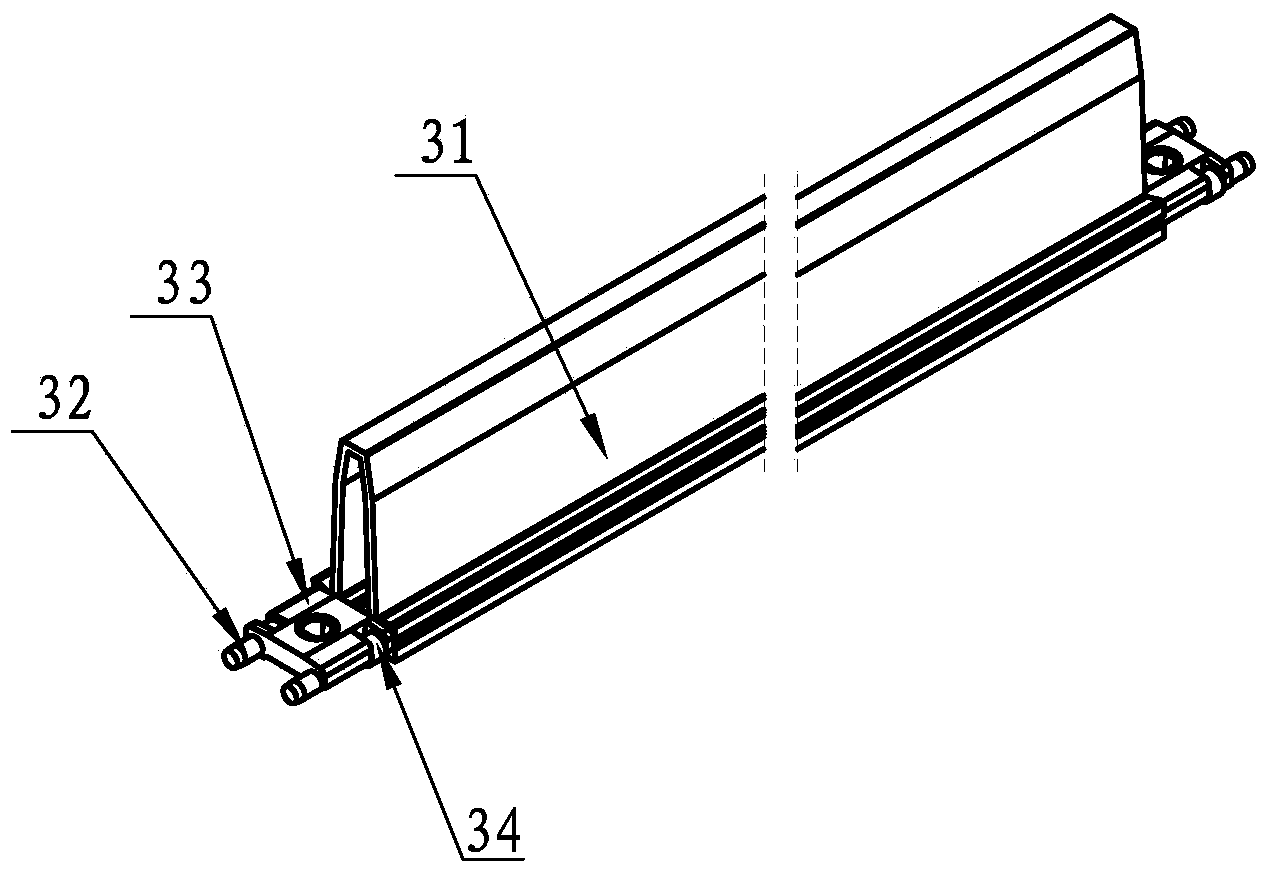

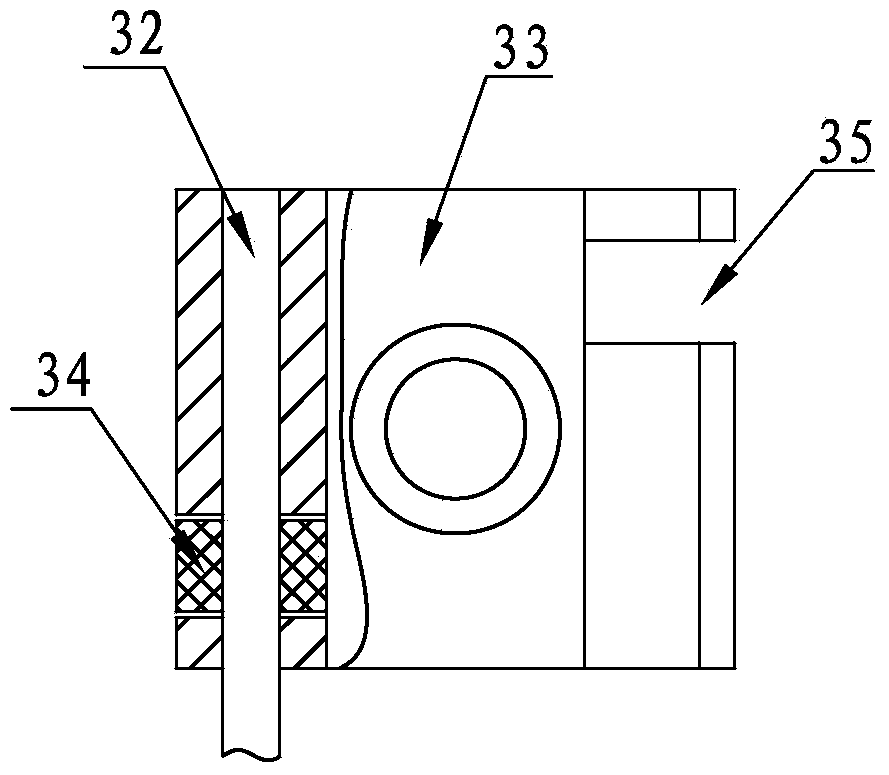

[0018] A carding machine movable cover carding device, such as Figure 1~4 As shown, it includes cylinder 1, guide rail 2, movable cover 3, driving wheel 4, driven wheel 5, tensioner 6 and transition wheel 7, guide rail 2 is fixedly installed on the cover plate of cylinder 1, movable cover 3 Rotate along the guide rail 2, the movable cover 3 includes a cover frame 31, a cover pin 32, a fixed block 33 and a bearing roller sleeve 34, the cover pin 32 is fixedly connected to the bottom two ends of the cover frame 31, fixed The block 33 is sleeved on the pin shaft 32 of the cover plate, and a limit groove 35 is respectively opened on the fixed block 33 corresponding to the two pin shaft holes. The positions of the two limit grooves 35 are staggered along the axial direction of the pin shaft, and the bearing roll The sleeve 34 is set on the cover plate pin 32 in the limit groove 35 of the fixed block 33, the inner hole of the bearing roller 34 and the cover pin 32 are clearance fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com