Method for the manufacturing of yarns from recycled carbon fibers

a technology of carbon fiber and manufacturing method, which is applied in the field of manufacturing a semi-finished product starting from recycled carbon fiber, can solve the problems of not being able to effectively re-use recycled fibers in an industrial, affecting the formability of complex-shape components, and not being able to solve the problem of disposed of components manufactured therewith at the end of their service life, etc., to achieve the effect of reducing cost, reducing wrinkling in the reinforcement of composi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

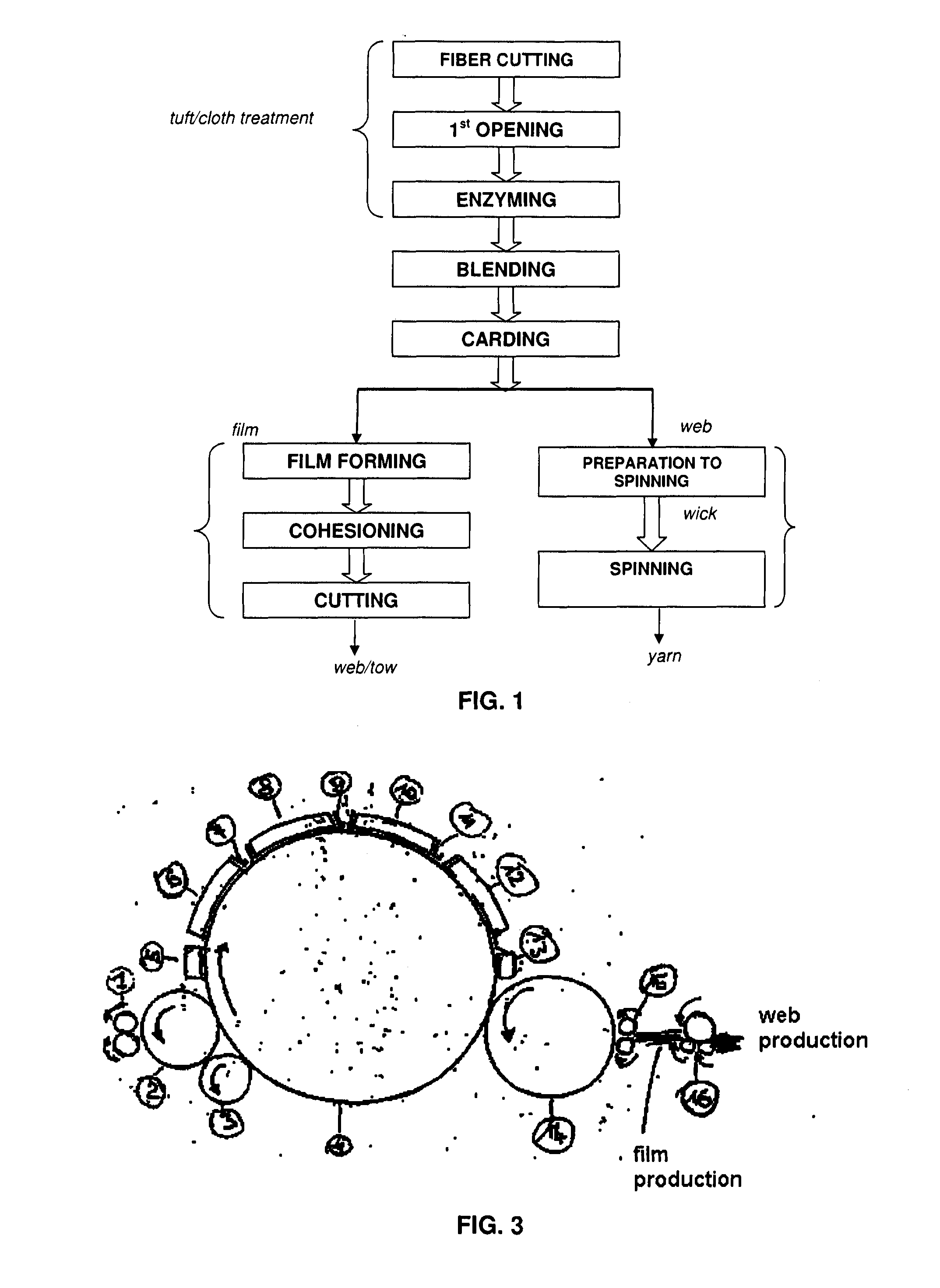

[0037]Referring initially to FIG. 1, it shows a sequence of steps according to a preferred embodiment of the method of the invention for the manufacturing of semi-finished products starting from recycled carbon fibers.

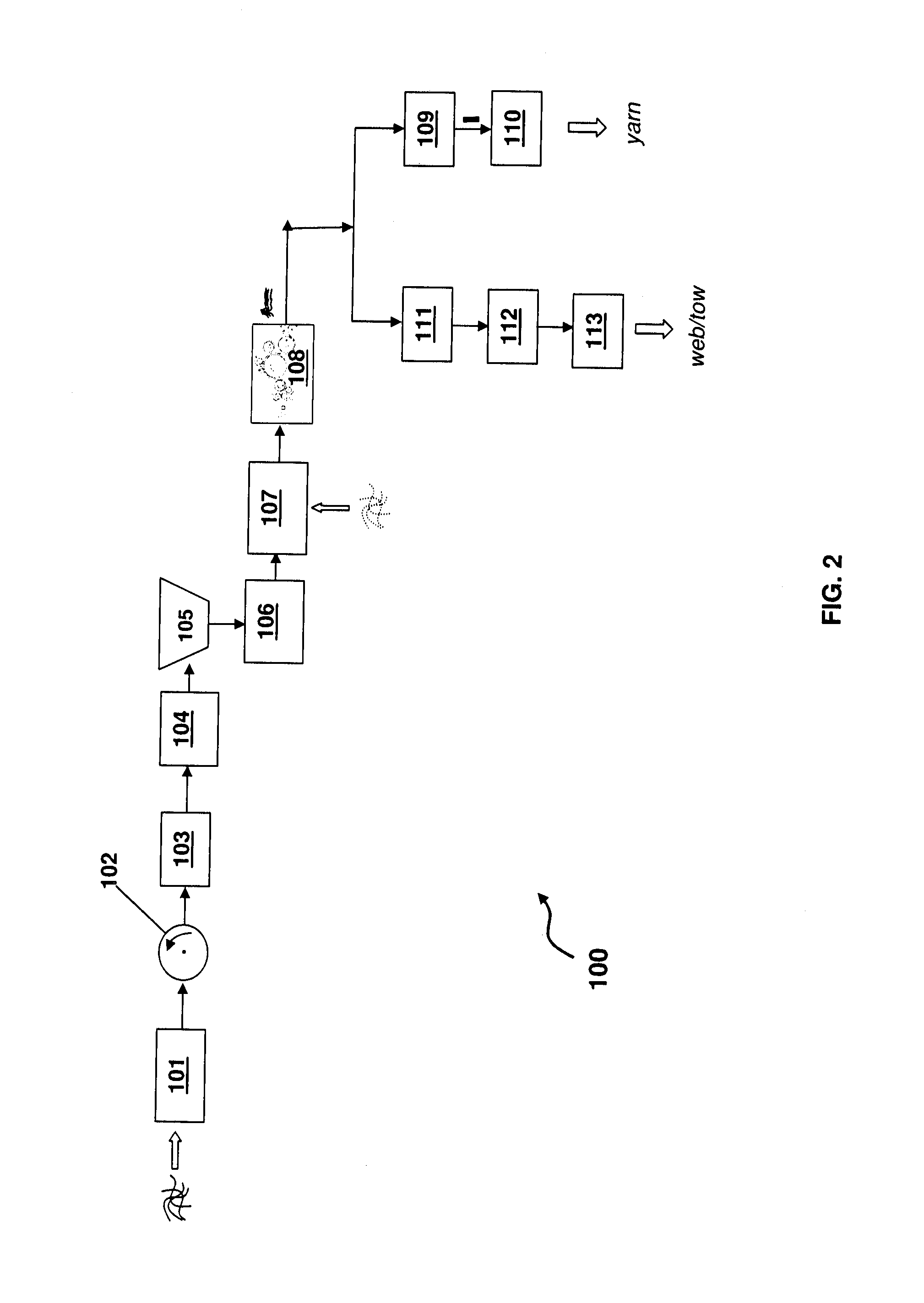

[0038]Correspondingly, FIG. 2 shows a preferred embodiment of an apparatus specifically suitable for the carrying out of the above-mentioned method, apparatus generally denoted by 100.

[0039]In the present embodiment of method and of apparatus, these work on carbon fibers as provided as output by the method of which at the aforecited WO 2003 / 089212, incorporated herein by this reference. In particular, in the present example recovered carbon fibers, initially in the form of tuft or cloth, are considered.

[0040]In general, as mentioned hereto, the method and the apparatus of the invention are suitable to the treatment of carbon fibers recovered from the recycle of composite materials or waste from the processing of virgin carbon fibers.

[0041]Thus, referring to FIGS. 1 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com