Blended yarn and spinning process thereof

A blended yarn and process technology, applied in the field of spinning, can solve the problems of poor hand feel, skin-friendly cohesion and spinnability, etc., and achieve the effects of improving hand feel, less neps, and poor wrinkle resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Raw materials.

[0024] The fiber content blending ratio is 50% cotton fiber, 40% cotton fiber, and 10% soybean protein fiber. The cotton fiber grade is 230A Xinjiang fine-staple cotton, the bamboo pulp fiber specification is 1.56dtex*38mm, and the soybean protein fiber specification is 1.67dtex*38mm. The mixing method of the three-component yarn composed of three raw materials is a combination of two methods of entrapment and strip mixing.

[0025] Yarn gauge: 14.7tex.

[0026] 2. Process flow.

[0027] FA002A type automatic plucking machine---A035D type mixed cotton opener---FA106 type cotton opener---A092E type cotton feeder---FA046 lapping machine---A186G carding machine---bamboo pulp Fiber and soybean combined + combed slivers --- FA302 draw frame --- THF4433 roving frame --- SXF1568C spinning frame --- SMARO automatic winder.

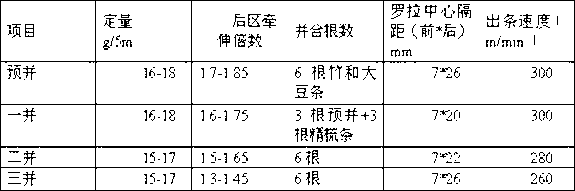

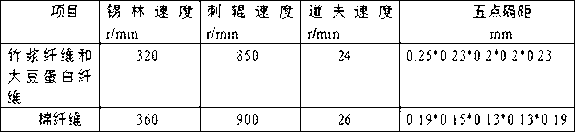

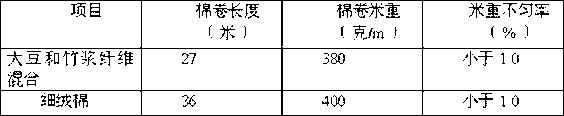

[0028] 3. Process configuration.

[0029] 3.1 Start cleaning process.

[0030] Soybean protein fiber has poor cohesion and light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com