Aromatic polysulphone/antistatic fibre mixed yarn and production method thereof as well as loosening and mixing device

An antistatic fiber, production method technology, applied in fiber mixing, fiber processing, textile and papermaking, etc., can solve the problems of low yarn strength, difficult to spin yarn, poor yarn evenness, etc., to overcome safety Hidden danger, excellent flame retardant performance, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 32S / 2 98 / 2 sulfonamide / conductive fiber blended yarn and its production and processing

[0016] Raw material specifications: sulfonamide is 2D*51mm; conductive fiber with carbon fiber as the core and nylon as the coating layer is 3D*51mm

[0017] 1. Opening and mixing process

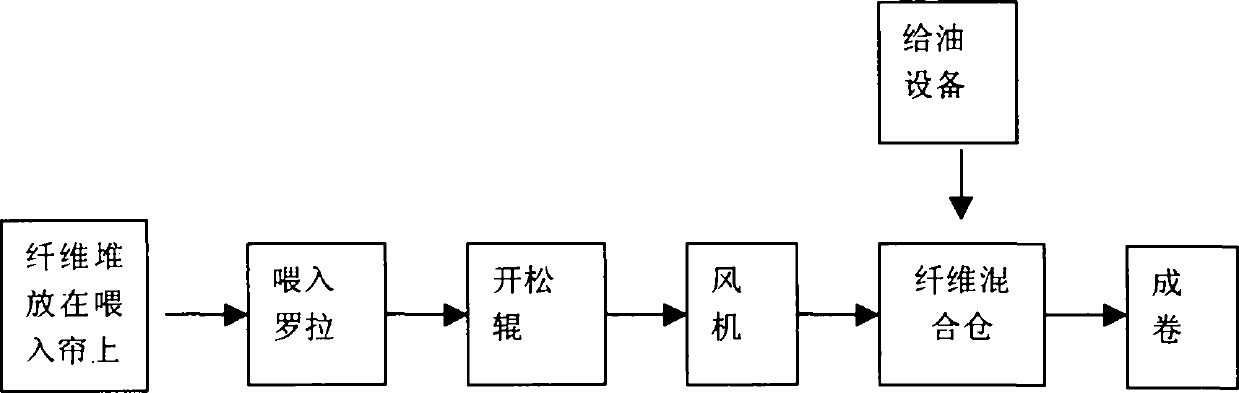

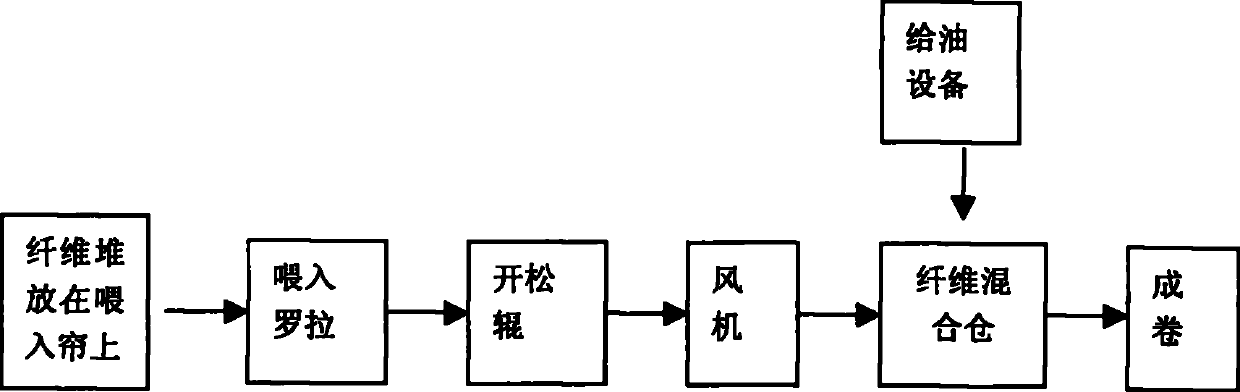

[0018] 1) Opening and mixing is carried out by adopting a self-designed opening and mixing device. The opening and mixing device is composed of a feeding curtain, a feeding roller, an opening roller, a fan, an oil supply device and a fiber mixing bin.

[0019] 2) Weigh 9.8kg of arylsulfone fibers, 0.2kg of conductive fibers, a total of 10kg of fibers as a group, one group of one group is stacked on the feeding curtain, and the feeding roller and opening roller are opened, and the fiber is sucked by the fan. Mixing chamber, fan speed 850r / min, mixed by air flow.

[0020] 3) Polysulfonamide and other fibers are repeatedly tumbled and mixed in the fiber mixing chamber. When the fibers reach a loos...

Embodiment 2

[0036] 21S / 2 95 / 5 sulfonamide / metal fiber blended yarn and its production and processing

[0037] Raw material specifications: sulfonamide is 2D*51mm; metal fiber is 0.8μm×51mm

[0038] 1. Opening and mixing process

[0039] 1) The opening and mixing equipment designed independently is used for opening and mixing. The opening and mixing equipment is composed of feeding curtains, feeding rollers, opening rollers, fans, oil supply equipment and fiber mixing bins.

[0040] 2) Weigh 9.5kg of arylsulfone fibers, 0.5kg of conductive fibers, a total of 10kg of fibers as a group, one group is stacked on the feeding curtain in turn, the feeding rollers and opening rollers are opened, and the fibers are sucked by the fan Mixing chamber, fan speed 940r / min, mixed by airflow.

[0041] 3) After sulfonamide and other fibers are repeatedly tumbled and mixed in the fiber mixing chamber, when the fibers reach a loose state, the fibers are oiled, and the oil is prepared according to 1.0% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com