Flame-proof electrostatic resistance yarn and its processing method

A flame-retardant, anti-static, processing method technology, applied in the direction of yarn, textiles, papermaking, fiber treatment, etc., can solve the problems of weakened flame-retardant effect, achieve short after-flame time, less stringent process requirements, flame-retardant and anti-static The effect is permanent and does not fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

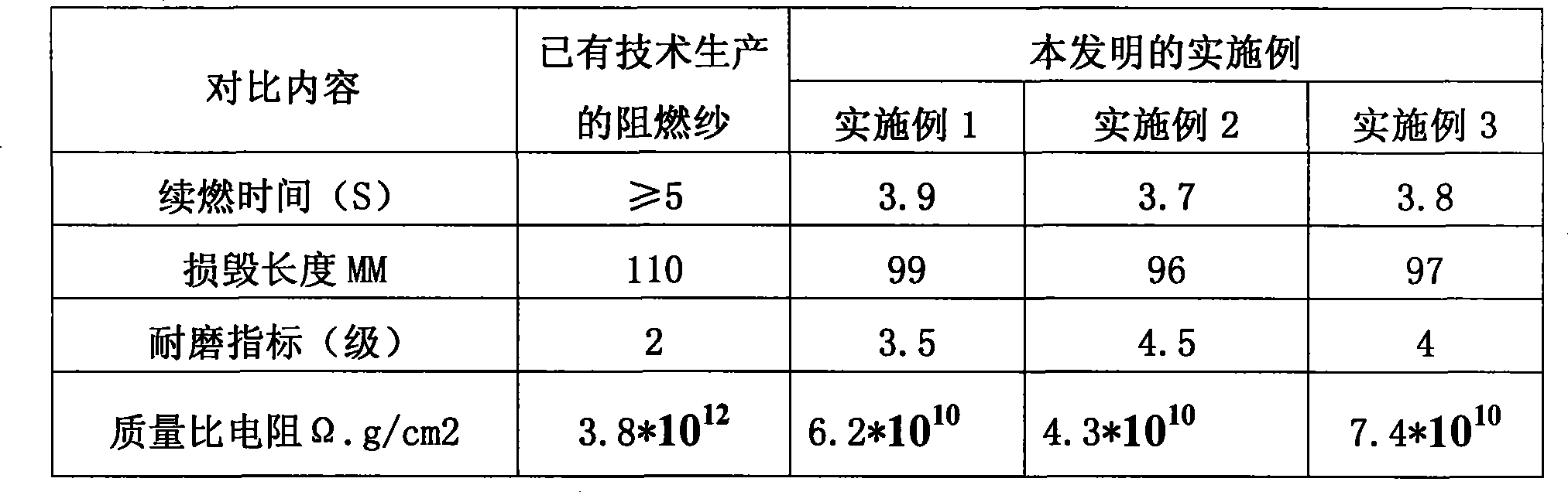

Examples

Embodiment 1

[0028] Using meta-aramid fibers, para-aramid fibers and antistatic fibers to process a yarn number of 19.7tex flame-retardant antistatic yarns, of which: the weight percentage of meta-aramid fibers is 93%, and para-aramid fibers The weight percentage of the antistatic fiber is 5% and the weight percentage of the antistatic fiber is 2%, and the processing steps are as follows.

[0029] A). Preparation of mixed fiber, the specification of 94.9% by weight is the meta-aramid fiber of 2.5D × 51mm and the specification of 5.1% by weight is the para-aramid fiber of 1.5D × 51mm for the spinning industry The usual cotton blending machine is used to mix the meta-aramid fiber and the para-aramid fiber while spraying the antistatic emulsion. The antistatic emulsion is obtained by dissolving the antistatic agent in water. The antistatic agent The concentration in water is 3.5%, that is, every 100g of water contains 3.5g antistatic agent, and the spraying amount of antistatic emulsion is 2....

Embodiment 2

[0038] Change the weight percent of meta-aramid fiber to 70%, change the weight percent of para-aramid fiber to 26%, change the weight percent of organic antistatic fiber to 4%, and change the number of flame-retardant antistatic yarn to It is 16.4tex.

[0039] Only change the percentage by weight of the meta-aramid fiber in step A) into 72.9%, change the percentage by weight of the para-aramid fiber into 27.1%, and change the concentration of antistatic agent in water into 2.5%; An antistatic fiber strip and seven aramid mixed fiber pre-drawings are merged to make an antistatic fiber pre-mixed strip containing 0.58 grams of antistatic fiber per meter, and then 6 aramid mixed fiber pre-drawings are combined with 2 antistatic fiber premixed strips are mixed; in step F), only the total draft ratio, jaw gap, traveler type and twist of the compact spinning machine are changed, so that the dry weight is 1.56g / 100m, and the twist is 1.56g / 100m. It is a blended compact yarn with 85 ...

Embodiment 3

[0041] Change the weight percentage of meta-aramid fiber to 85%, the weight percentage of para-aramid fiber to 13.5%, change the weight percentage of organic antistatic fiber to 1.5%, and the yarn number of flame-retardant antistatic yarn Change the number to 24.6tex.

[0042] Only change the percentage by weight of the meta-aramid fiber in step A) into 86.3%, change the percentage by weight of para-aramid fiber into 13.7%, and change the concentration of antistatic agent in water into 2.8%; 1 antistatic fiber strip and 7 aramid blended fiber pre-drawings are combined to make antistatic fiber premixed strips containing 0.45 grams of antistatic fiber per meter; change the total traction of the compact spinning machine in step F) Elongation, jaw gap and traveler type and twist, so as to obtain dry basis weight is 2.34g / 100m, twist is the blended compact yarn of 70 twists / 10cm; Change the vacuum in step G) to be-0.06Mpa, temperature 90 ℃ and holding time is 115min. All the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com