Non-molten-drop flame-retardant polyurethane adhesive and non-molten-drop flame-retardant reflective hot paste

A technology of polyurethane adhesive and polyurethane adhesive layer, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, film/sheet adhesive, etc., and can solve the secondary combustion hazard, secondary combustion, and smoldering of adhesive layer materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

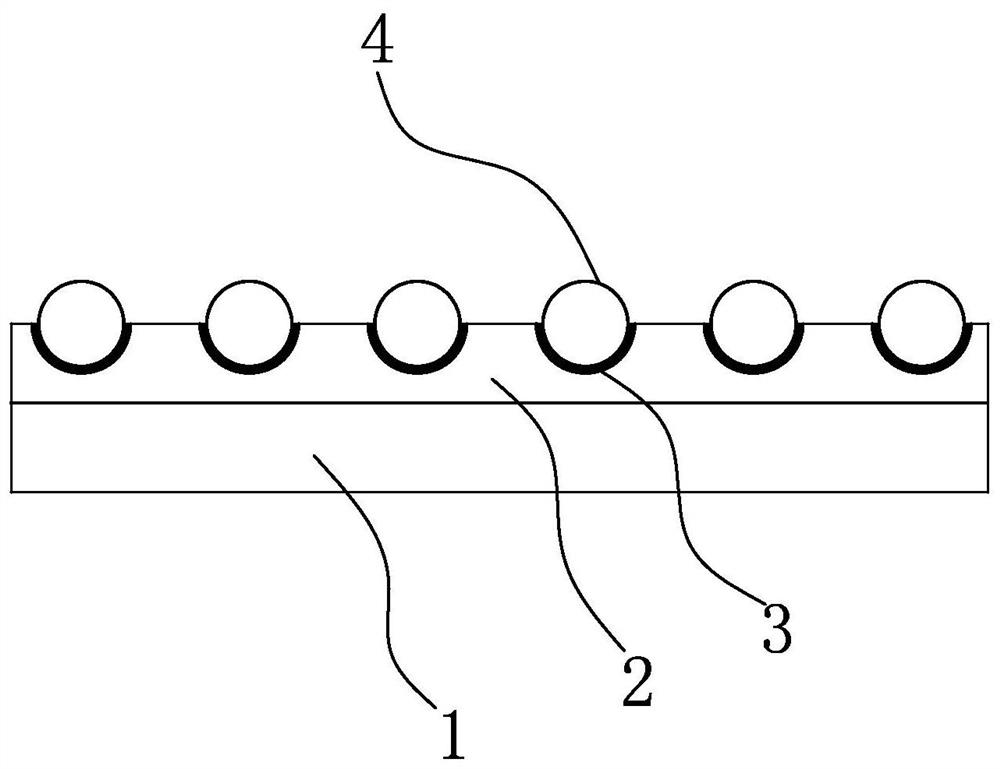

Image

Examples

Embodiment 1

[0039] This non-droplet flame retardant polyurethane adhesive consists of the following components by mass percentage:

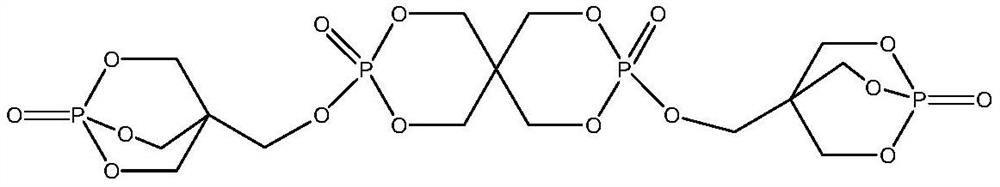

[0040] Spirocyclic phosphate: 5.0%; Aluminum hydroxide: 2.0%; Fumed silica: 6.0%, the particle diameter of fumed silica is 200nm; MPP (melamine phosphate): 3.0%; ADP (diethyl hypophosphorous acid Aluminum): 10%; the rest is polyurethane, which is equivalent to adding the composite flame retardant in the above mass percentage to the non-droplet flame retardant polyurethane glue. Wherein the spirocyclic phosphate adopts the spirocyclic-cage structure phosphate of following structural formula:

[0041]

[0042] Further, wherein, the polyurethane in the non-droplet flame-retardant polyurethane glue of this embodiment is mainly made of the following raw materials in parts by weight:

[0043] Hydroxyethyl methacrylate: 15; Hydroxypropyl acrylate: 10; Methyl methacrylate: 16; Butyl acrylate: 9.0; Acrylic acid: 5.0; 1,4-butanediol: 8.0; 1,6-hexanediol Alcohol: ...

Embodiment 2

[0046] This non-droplet flame retardant polyurethane adhesive consists of the following components by mass percentage:

[0047] Spirocyclic phosphate: 8.0%; Aluminum hydroxide: 4.0%; Fumed silica: 9.0%, the particle diameter of fumed silica is 300nm; MPP (melamine phosphate): 2.5%; ADP (diethyl hypophosphorous acid Aluminum): 8.0%; the rest is polyurethane, which is equivalent to adding the composite flame retardant in the above mass percentage to the non-droplet flame retardant polyurethane glue. Wherein the spirocyclic phosphate adopts the spirocyclic-cage structure phosphate of following structural formula:

[0048]

[0049] Furthermore, the non-droplet flame-retardant polyurethane glue of this embodiment is mainly made of the following raw materials in proportion by weight:

[0050] Hydroxyethyl methacrylate: 10; Hydroxypropyl acrylate: 8.0; Methyl methacrylate: 10; Butyl acrylate: 8.0; Acrylic acid: 7.0; 1,4-butanediol: 5.0; 1,6-hexanediol Alcohol: 13; Trimethylolpro...

Embodiment 3

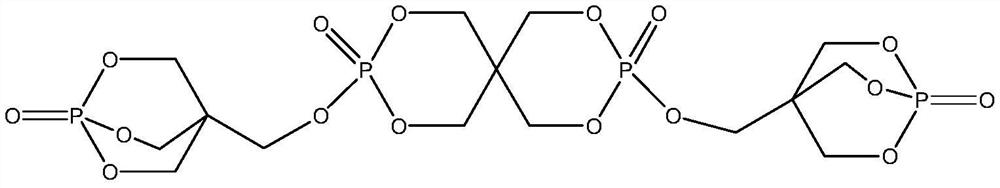

[0053] This non-droplet flame retardant polyurethane adhesive consists of the following components by mass percentage:

[0054]Spirocyclic phosphate: 10%; Aluminum hydroxide: 5.0%; Fumed silica: 8.0%, the particle size of fumed silica is 260nm; MPP (melamine phosphate): 2.5%; Calcium diethyl hypophosphite: 7.0%; the rest is polyurethane, which is equivalent to adding the composite flame retardant in the above mass percentage to the non-droplet flame retardant polyurethane glue. Wherein the spirocyclic phosphate adopts the double spirocyclic phosphate of the following structural formula:

[0055]

[0056] Further, wherein, the polyurethane glue of the present embodiment is mainly made from the following raw materials in parts by weight:

[0057] Hydroxyethyl methacrylate: 12; Hydroxypropyl acrylate: 5.0; Methyl methacrylate: 11; Butyl acrylate: 7.0; Acrylic acid: 7.0; 1,4-butanediol: 6.0; 1,6-hexanediol Alcohol: 9.0; Trimethylolpropane: 5.0; Aminoethylaminopropyl Dimethico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry film thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com