Preparation method for nitrogen-containing silica sol synergistic phosphorus flame-retardant epoxy acrylate coating layer

A technology of epoxy acrylate and methacrylic acid, which is applied in the field of flame retardant materials, and can solve the problems of large amount of addition, low burning rate, and easy formation of ammonia water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

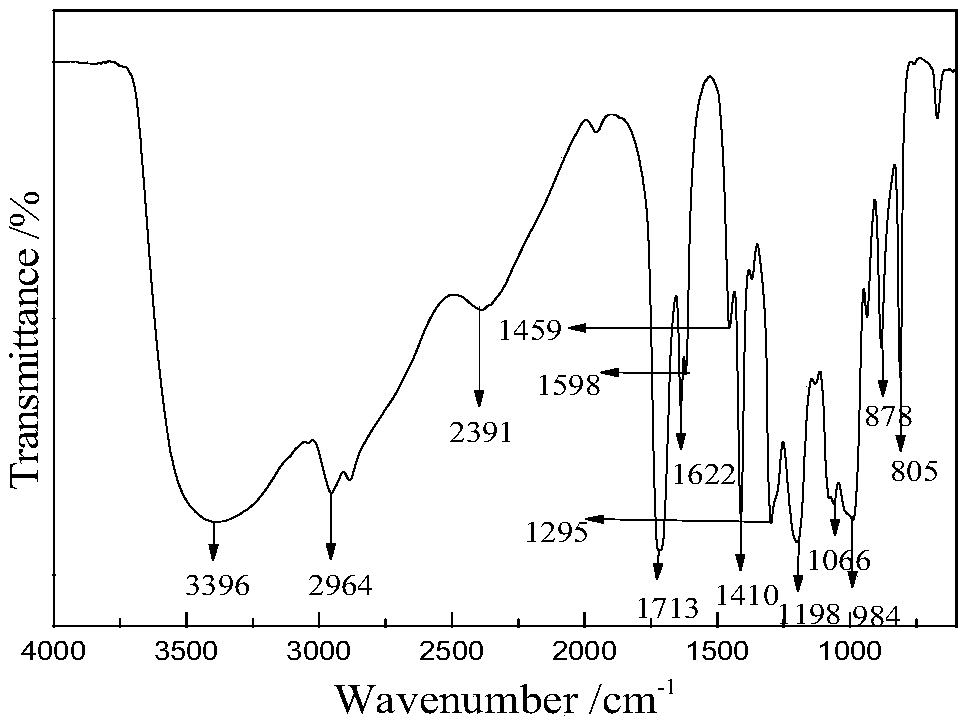

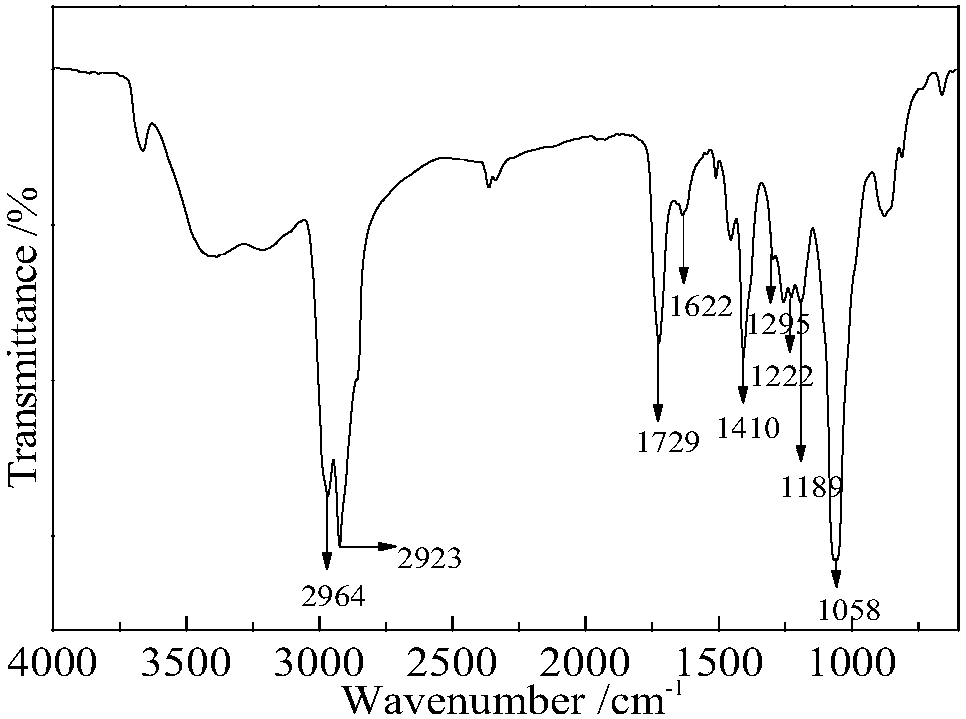

Image

Examples

preparation example Construction

[0027] A method for preparing a nitrogen-containing silicon sol synergistic phosphorus flame-retardant epoxy acrylate coating, comprising the following steps:

[0028] 1) Preparation of nitrogen-containing silica sol

[0029] Add silane coupling agent KH-570, silane coupling agent KH-550 and distilled water into the beaker, place in a magnetic oil bath and stir, the silane coupling agent KH-570, silane coupling agent KH-550 and distilled water The molar ratio is 0.13-0.17: 0..8-1.2: 0.1 (preferably 0.15: 0.1: 0.1), then slowly add dilute hydrochloric acid with a concentration of 0.8-1.2mol / L until the pH of the solution is 1-2 , then heated to 45-55°C, reacted for 2.5-3.5h, and dried the product in a vacuum oven at 28-35°C for 2.5-3.5h to obtain a colorless transparent viscous solution, namely nitrogen-containing silica sol; the reaction formula is as follows :

[0030]

[0031] Synthetic reaction formula of formula 1 nitrogen-containing silica sol

[0032] 2) Preparatio...

Embodiment 1

[0040] Preparation of nitrogen-containing silica sol

[0041]Add 0.15mol of KH-570 and 0.10mol of KH-550 silane coupling agent and 0.10mol of distilled water into a 250mL beaker, place in a magnetic oil bath and stir, slowly add dilute hydrochloric acid with a concentration of 1mol / L dropwise until The pH value of the solution is between 1-2. Heat to 50°C, react at this temperature for 3 hours, and place in a vacuum oven at 30°C to dry for 3 hours after the reaction is completed, to obtain a colorless transparent viscous solution, ie nitrogen-containing silica sol.

Embodiment 2

[0043] Preparation of TGMAP

[0044] Take 0.1 mol of phosphoric acid in a 500 mL round bottom flask, place it in an ice-water bath and stir, add 0.3 mol of glycidyl methacrylate (GMA) dissolved in 100 mL of acetone dropwise, and then add 0.13 g of phenol. The above-mentioned flask was transferred to an oil bath and heated to 80°C, reacted for 8 hours, then cooled to 60°C, and distilled under reduced pressure for 3 hours to obtain the colorless product TGMAP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com