A droplet-free flame retardant polyurethane adhesive and a droplet-free flame retardant reflective thermal paste

A technology of polyurethane glue and polyurethane glue layer, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, film/sheet adhesive, etc., and can solve the problem of long afterburning time, secondary combustion, and affecting flame retardancy, etc. problems, to achieve the effects of high phosphorus content and thermal stability, good synergistic effect, and short afterburn time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

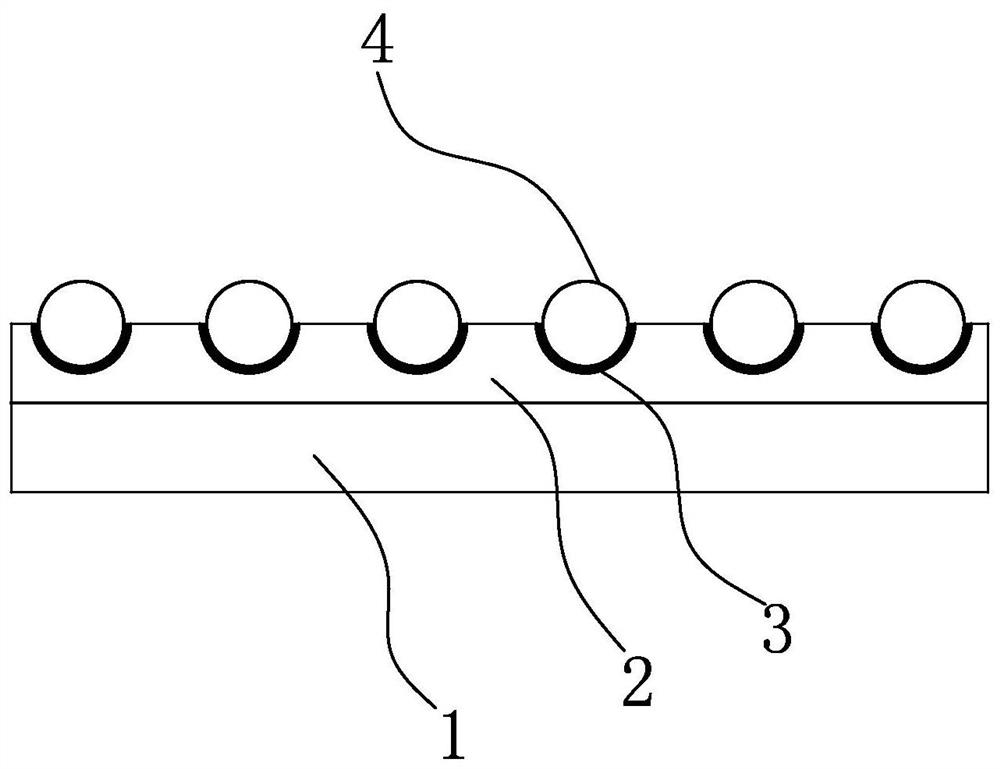

Image

Examples

Embodiment 1

[0039] The non-droplet flame retardant polyurethane adhesive comprises the following components in mass percentage:

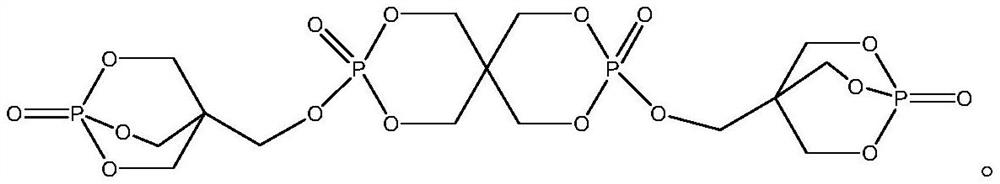

[0040] Spirocyclic phosphate: 5.0%; Aluminum hydroxide: 2.0%; Fumed silica: 6.0%, the particle size of the fumed silica is 200 nm; MPP (melamine phosphate): 3.0%; ADP (diethyl hypophosphorous acid) Aluminum): 10%; the rest is polyurethane, which is equivalent to adding the above-mentioned composite flame retardant to the non-droplet flame retardant polyurethane glue. Wherein the spirocyclic phosphoric acid ester adopts the spirocyclic-cage structure phosphoric acid ester of the following structural formula:

[0041]

[0042] Further, wherein, the polyurethane in the non-droplet flame retardant polyurethane adhesive of the present embodiment is mainly made of the following raw materials in parts by weight:

[0043] Hydroxyethyl methacrylate: 15; Hydroxypropyl acrylate: 10; Methyl methacrylate: 16; Butyl acrylate: 9.0; Acrylic acid: 5.0; 1,4-Butanediol: 8.0; ...

Embodiment 2

[0046] The non-droplet flame retardant polyurethane adhesive comprises the following components in mass percentage:

[0047] Spirocyclic phosphate: 8.0%; Aluminum hydroxide: 4.0%; Fumed silica: 9.0%, the particle size of fumed silica is 300 nm; MPP (melamine phosphate): 2.5%; ADP (diethyl hypophosphorous acid) Aluminum): 8.0%; the rest is polyurethane, which is equivalent to adding the above-mentioned composite flame retardant to the non-droplet flame retardant polyurethane glue. Wherein the spirocyclic phosphoric acid ester adopts the spirocyclic-cage structure phosphoric acid ester of the following structural formula:

[0048]

[0049] Further, wherein, the droplet-free flame retardant polyurethane adhesive of the present embodiment is mainly made of the following raw materials in parts by weight:

[0050] Hydroxyethyl methacrylate: 10; Hydroxypropyl acrylate: 8.0; Methyl methacrylate: 10; Butyl acrylate: 8.0; Acrylic acid: 7.0; 1,4-Butanediol: 5.0; Alcohol: 13; Trimeth...

Embodiment 3

[0053] The non-droplet flame retardant polyurethane adhesive comprises the following components in mass percentage:

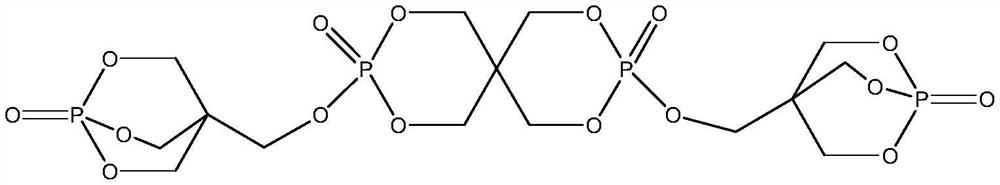

[0054]Spiro phosphate: 10%; Aluminum hydroxide: 5.0%; Fumed silica: 8.0%, the particle size of fumed silica is 260 nm; MPP (melamine phosphate): 2.5%; Diethyl calcium hypophosphite: 7.0%; the rest is polyurethane, which is equivalent to adding the above-mentioned composite flame retardant to the non-droplet flame retardant polyurethane glue. Wherein the spirocyclic phosphate adopts the double spirocyclic phosphate of the following structural formula:

[0055]

[0056] Further, wherein, the polyurethane glue of the present embodiment is mainly made of the following raw materials in parts by weight:

[0057] Hydroxyethyl methacrylate: 12; Hydroxypropyl acrylate: 5.0; Methyl methacrylate: 11; Butyl acrylate: 7.0; Acrylic acid: 7.0; 1,4-Butanediol: 6.0; Alcohol: 9.0; Trimethylolpropane: 5.0; Aminoethylaminopropyl Dimethicone: 5.5; Toluene Diisocyanate: 30; Eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com