Cotton blending device and cotton blending method

A technology of cotton blending and cotton blending box, which is applied in the fields of fiber mixing, textile and papermaking, fiber processing, etc., can solve the problems of non-standard fiber content ratio of fabrics, color difference of fabric shades, and large variation of yarn strength, and achieve optimization. The effect of production process, labor saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

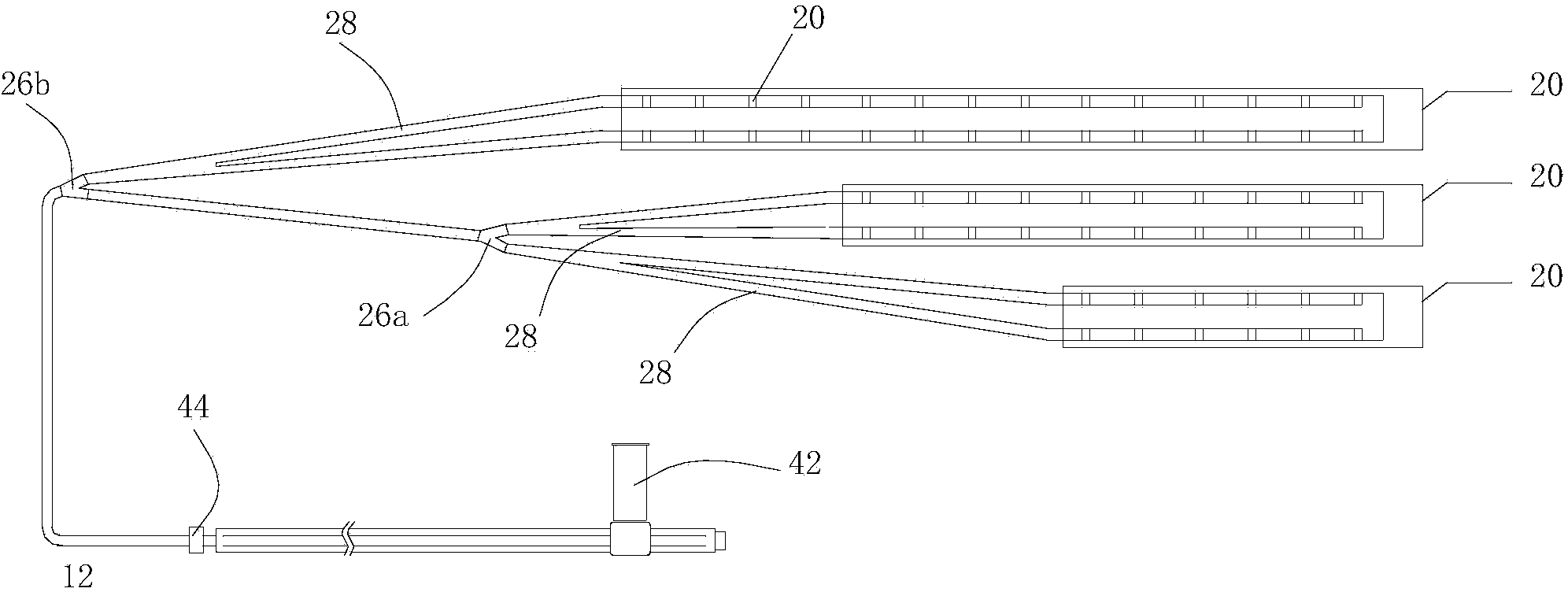

Embodiment 1

[0070] Assuming that the total feeding amount of white cotton is 5000 kg, according to the inventory of raw materials and the indicators of raw cotton (such as length, whiteness, maturity, etc.), it is necessary to mix and feed the three kinds of cotton after calculation, and the feeding amount of each type of cotton is respectively For 2000kg, 2000kg and 1000kg. Assuming that the weight of each cotton bale is 100 kg, it is calculated that each of the three kinds of cotton needs 20 bales, 20 bales and 10 bales respectively. These 50 bales of cotton are lined up in a team, each team has two rows, and are put on the catching cotton trolley 11 times.

[0071] The cotton mixing method of the cotton mixing device is as follows:

[0072] A Cotton Fiber Raw Materials Horizontally Layered and Cotton Blended

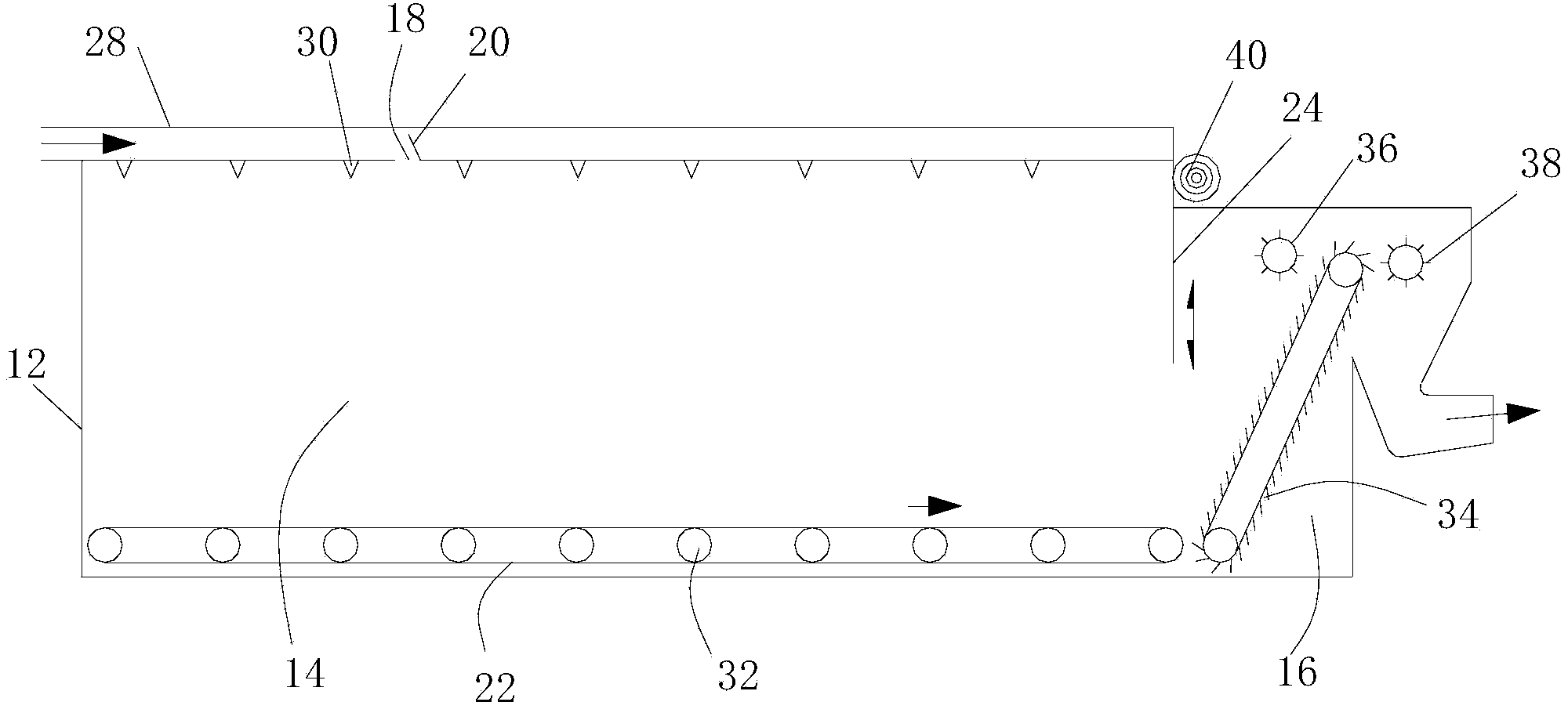

[0073] The insert plate 24 in the cotton mixing box 12 is inserted downwards to seal and separate the cotton laying area 14 and the cotton grasping area 16 . Start the control...

Embodiment 2

[0079] Assuming that the total feeding amount of colored cotton is 1200 kg, a total of 12 kinds of colored cotton are dyed; among them, 4 kinds of colored cotton are colored cotton of color tone, accounting for 90% of the total amount, which is 1080 kg, and the other 8 kinds of colored cotton are for toning Light and lightness together only account for 10%, which is 120 kg. Assuming that the weight of each package of colored cotton is 100 kilograms, among the 4 kinds of colored cotton of color tone, A colored cotton is 3.133 packages, B colored cotton is 2.077 packages, C colored cotton is 3.111 packages, and D colored cotton is 3.079 packages. The weight of the 8 kinds of colored cotton E, F...L of shade and lightness is less than the weight of a bale of cotton. First arrange 0.133 packs of colored cotton of A, 0.077 packs of colored cotton of B, 0.111 packs of colored cotton of C, 0.079 packs of colored cotton of D, and 8 kinds of colored cottons E, F...L (the weight is less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com