Composite carbon fiber

一种复合碳纤维、纤维径的技术,应用在纤维处理、纤维的混合、纤维化学特征等方向,能够解决结晶性低、导电性低等问题,达到改善容量维持率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0090] Examples of the present invention are shown below, and the present invention will be described more specifically. Furthermore, they are only examples for illustration, and the present invention is not limited by them in any way.

[0091] The properties and the like of the multilayered carbon nanotubes and carbon nanofibers were measured as follows.

[0092]

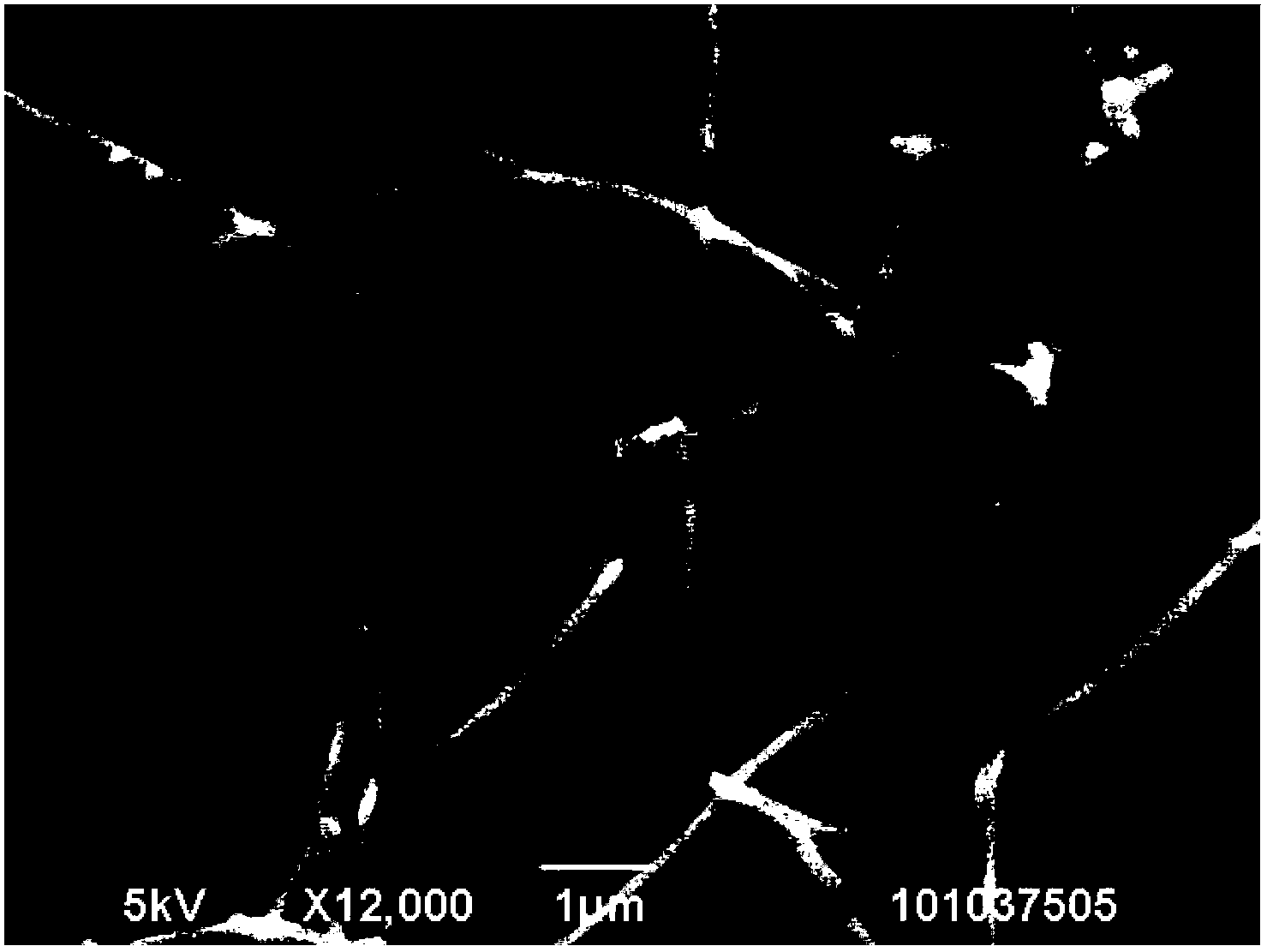

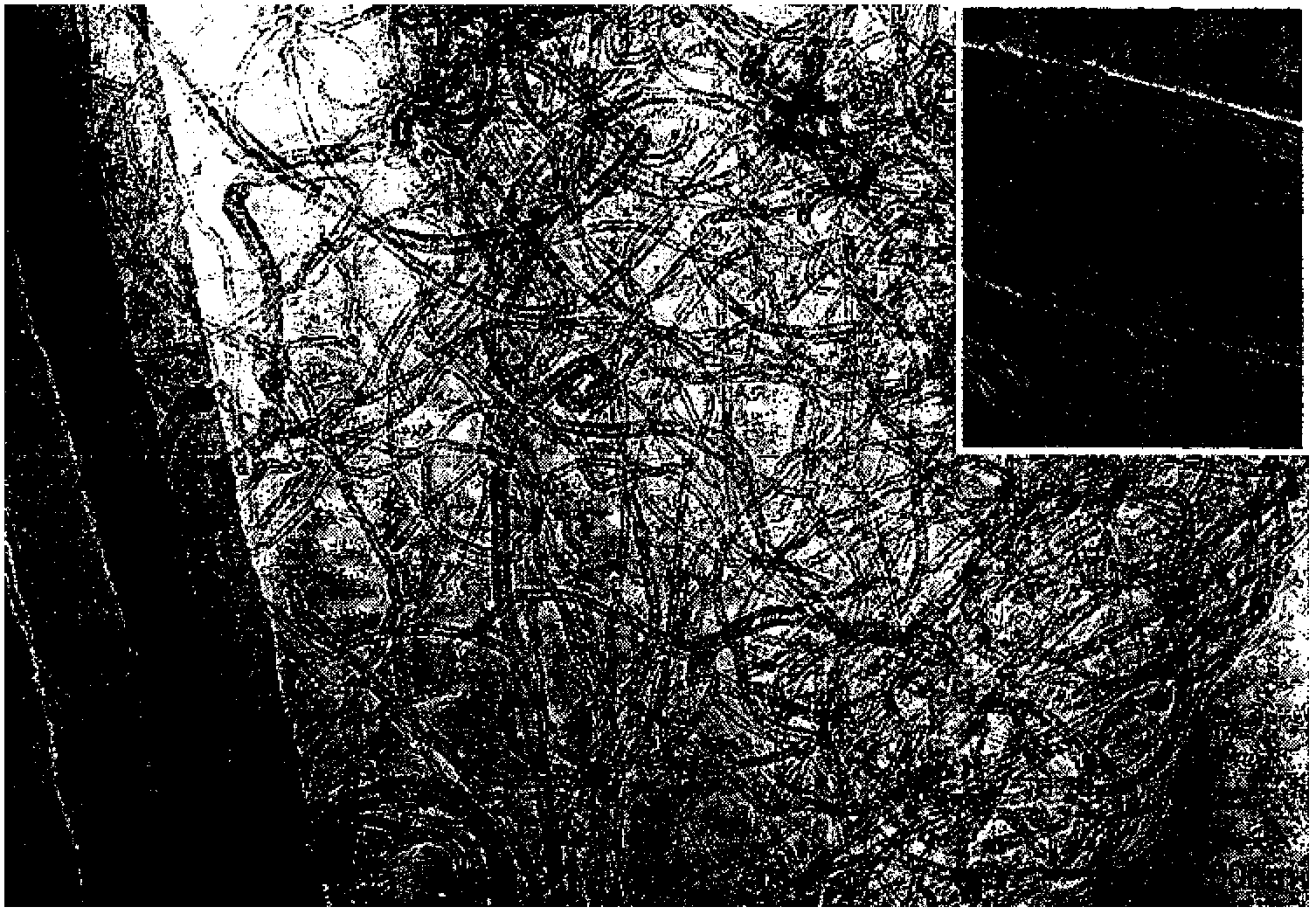

[0093] The object obtained by attaching the sample powder to a carbon tape and depositing gold was used as an observation sample, and the observation was carried out by JSM-6390 manufactured by JEOL Ltd.

[0094] scattered state

[0095] Observing a 10 field of view at a magnification of 20 k by a scanning electron microscope, it was determined whether the carbon nanofibers penetrated through the gaps of the carbon nanotubes disentangled into a loose state, and the disentangled carbon nanotubes were entangled in the vicinity of the surface of the carbon nanofibers. . The case where the above-mentioned dispe...

manufacture example 1

[0128] Production Example 1 (Catalyst Preparation)

[0129] Aluminum hydroxide (HIGILITE (registered trademark) M-43 manufactured by Showa Denko Co., Ltd.) was heat-treated at 850° C. for 2 hours in an atmosphere flowing with air to prepare a carrier.

[0130] 50 g of pure water was added to a 300 ml tall measuring cup, and 4.0 g of a carrier was added thereto and dispersed to prepare a carrier slurry.

[0131] 16.6 g of pure water was put into a 50 ml beaker, and 0.32 g of hexaammonium heptamolybdate tetrahydrate (manufactured by Junsei Chemical Co., Ltd.) was added and dissolved. Then, 7.23 g of iron (III) nitrate nonahydrate (manufactured by Kanto Chemical Co., Ltd.) was added and dissolved to prepare a catalyst solution.

[0132] Further, 32.7 g of pure water was put into another 50 ml beaker, and 8.2 g of ammonium carbonate (manufactured by Kanto Chemical Co., Ltd.) was added and dissolved therein to prepare a pH adjustment solution.

[0133] A stirring bar was placed i...

manufacture example 2

[0134] Production Example 2 (Synthesis of Multiwalled Carbon Nanotubes: MWCNT)

[0135] 1.0 g of the catalyst obtained in Production Example 1 was placed on a quartz boat. It was placed in the center of a horizontal tubular furnace (quartz tube: inner diameter 50 mm, length 1500 mm, soaking belt 600 mm). The temperature was raised to 680° C. over 30 minutes while circulating nitrogen gas at 500 ml / min in the horizontal tubular furnace. Then, the supply of nitrogen gas was stopped, a mixed gas of ethylene and hydrogen (ethylene concentration of 50% by volume) was circulated at 2000 ml / min, and the reaction was carried out for 20 minutes to synthesize multi-walled carbon nanotubes. The supply of the mixed gas was stopped, nitrogen gas was supplied, the mixture was cooled to room temperature, and the multilayered carbon nanotubes were taken out from the furnace.

[0136] Table 1 shows the fiber shape and the physical properties of the powder. exist figure 2 Transmission elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com