Mineral methane gas drainage pipe and production method thereof

A technology of gas drainage and manufacturing method, which is applied in gas discharge, pipes, rigid pipes, etc., can solve the problems of high cost of stainless steel pipes, poor anti-static and flame-retardant properties, and high use costs, and achieve excellent flame-retardant and anti-static properties. The effect of improved electrostatic properties and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

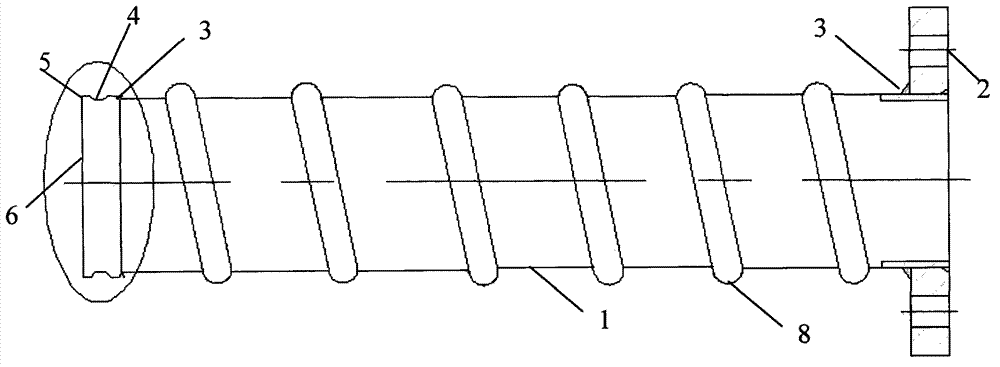

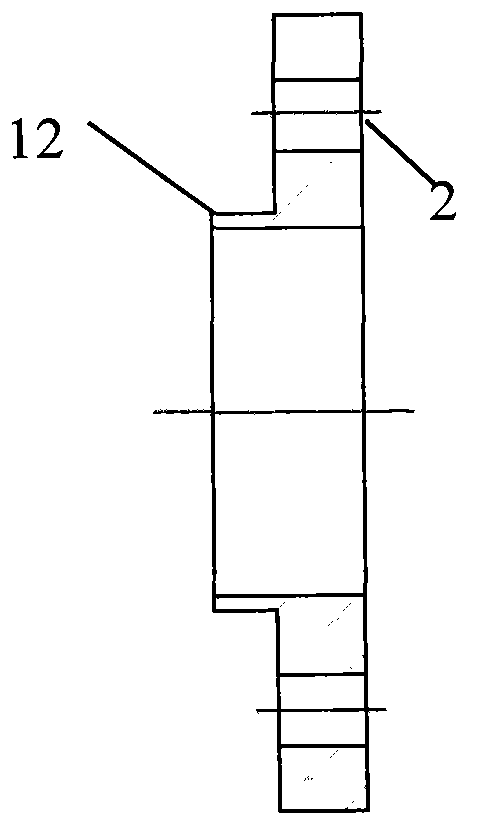

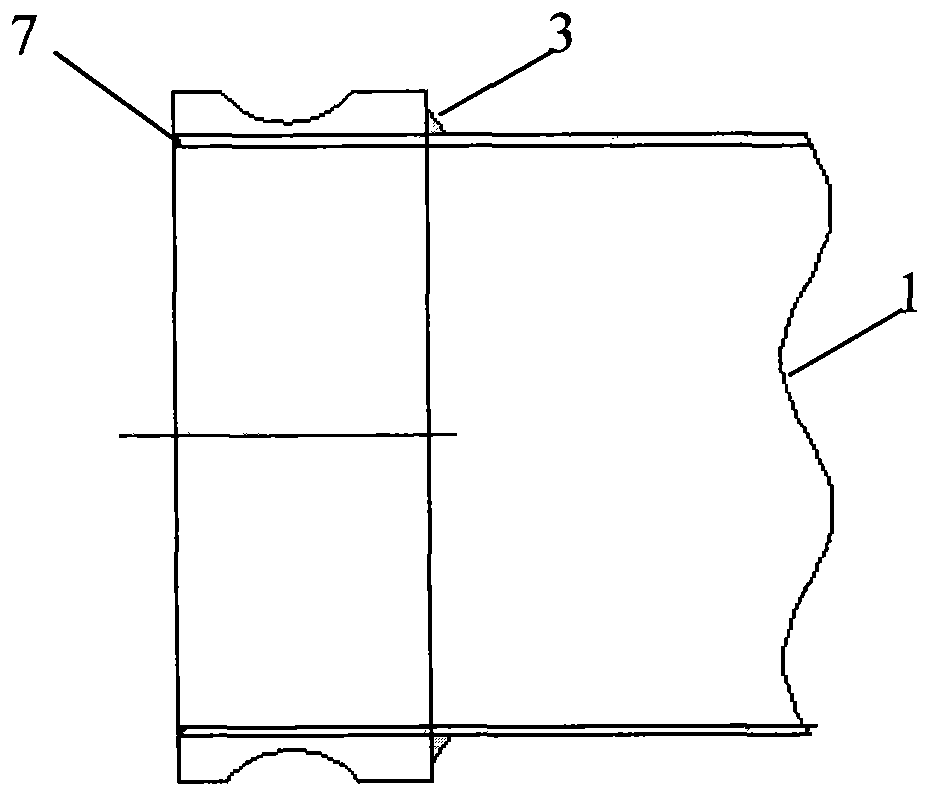

[0032] Embodiment 1 is a cold-rolled carbon structural steel strip, using a spiral welded corrugated steel pipe with a thickness of 2 mm and a width of 137 mm, and 219 in production. The method is: directly use the spiral air duct forming machine for production, rolling and forming, and then weld the inside and outside. The temperature of PE coating is controlled at 160-200 °C, and the temperature of EP coating is controlled at 140-160 °C. Others can be done according to conventional processes.

Embodiment 2

[0033] Embodiment two is a stainless steel strip, the method is the same as above, without coating.

Embodiment 3

[0034] Embodiment three is a stainless steel clad steel strip. The method is as follows: the thickness of the steel strip is 2mm, the width is 155mm, the thickness of the stainless steel composite layer is 0.2mm, and it is directly rolled into shape with a spiral air duct unit, and the welded part is welded with a stainless steel electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com