Silk-coating method for PVC/PU coating polyester industrial yarns and device thereof

A polyester industrial yarn and coating technology, which is applied in the direction of yarn, fiber type, textile and papermaking, etc., to achieve the effect of good toughness, uniform and stable mesh, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

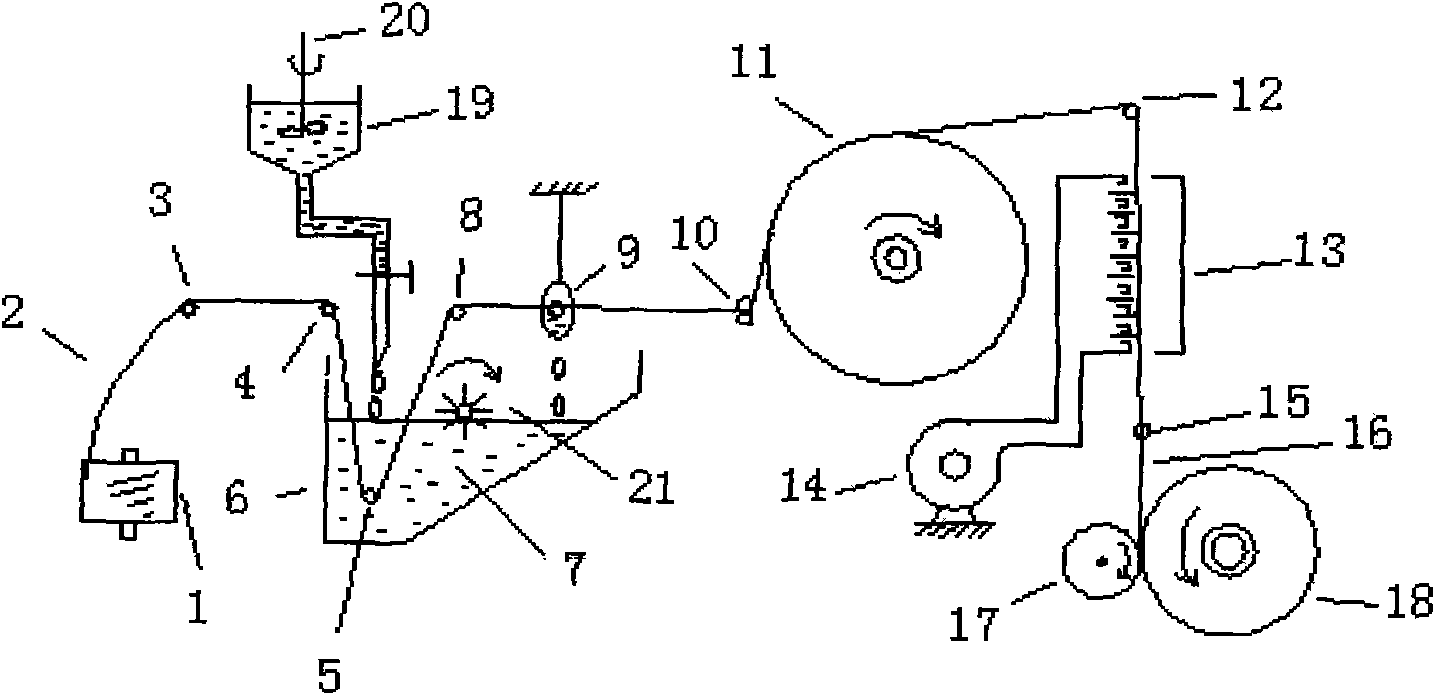

[0027] A thread coating method for PVC-coated polyester industrial yarn, using polyester industrial yarn and PVC coating adhesive as raw materials, using polyester industrial yarn as the core material, using PVC coating adhesive as the cortex material, and coating the polyester industrial yarn The tows are composited into monofilaments of skin-core structure. The specific process is that the polyester industrial yarn is dipped in PVC coating glue to hang the glue to make the silk thread glued. After the silk thread is glued, it is extruded and scraped, and then spirally wound on the infrared baking cylinder with a diameter of 300mm at a distance of 15mm. Baking, the baking temperature is 190°C, after the dried silk thread is cooled by blowing and coiled, the coating glue is deeply infiltrated and coated on the core layer polyester industrial thread to form a composite structure coated thread.

[0028] Coating equipment for the production of coated polyester industrial yarns, s...

Embodiment 2

[0033] A thread coating method for PU-coated polyester industrial yarn, which uses polyester industrial yarn and PU coating adhesive as raw materials, adopts polyester industrial yarn as the core material, adopts PU coating adhesive as the cortex material, and adds Nanoscale ZiO 2 Anti-ultraviolet and anti-aging agent, phosphorus flame retardant and ecological safety insect repellent, the polyester industrial tow is compounded into a skin-core structure monofilament after coating. The specific process is, first, the nano-sized ZiO 2 Anti-ultraviolet and anti-aging agents, phosphorus flame retardants, ecological safety insect repellents, etc. are uniformly dispersed and added to the PU coating adhesive in a certain proportion and mixed to form a PU functional coating adhesive, and then the polyester industrial yarn is added to the PU functional coating adhesive. The coating glue is soaked in hanging glue to make the silk thread glued. After the silk thread is glued, it is extr...

Embodiment 3

[0039] A thread coating method for PE-coated polyester industrial yarn, using polyester industrial yarn and PE coating adhesive as raw materials, using polyester industrial yarn as the core material, using PE coating adhesive as the cortex material, and adding Phosphorus-based flame retardant is added, and the polyester industrial tow is compounded into a skin-core structure monofilament after coating. The specific process is that first, the phosphorus-based flame retardant is uniformly dispersed and added to the PE coating glue in a certain proportion and mixed to form a PE functional coating glue, and then the polyester industrial yarn is impregnated with the glue in the PE coating glue. Apply glue to the silk thread, squeeze and scrape the glue after the thread is glued, and then wind it spirally on an infrared baking cylinder with a diameter of 350mm at a distance of 25mm for baking. The baking temperature is 200°C, and the dried silk thread is then blown After cooling and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com