Thermostable, flame-resistant and oil-proof rubber sizing material and production method thereof

A technology of oil-resistant rubber and production method, which is applied in the fields of oil-resistant rubber compound, flame retardant and high temperature resistance, and can solve the problems that there is no precedent for it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

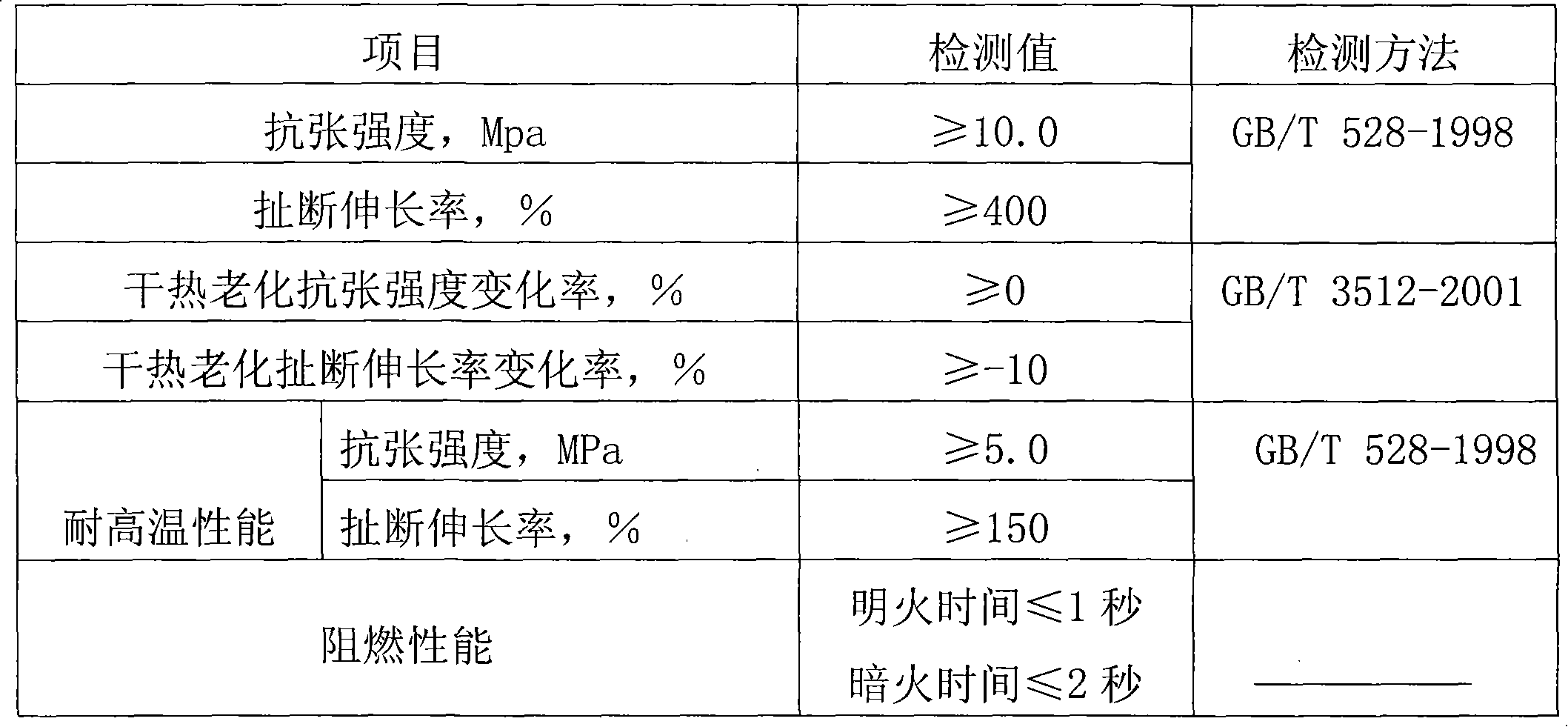

Image

Examples

Embodiment 1

[0017] High temperature resistant, flame retardant, oil resistant rubber compound, the formula is: nitrile rubber: 100phr; dimorpholine disulfide: 2phr; zinc oxide: 5phr; stearic acid: 2phr; N-cyclohexyl-2-benzothiazole Sulphenamide: 1phr; Zinc diethyldithiocarbamate: 3phr; Carbon black: 30phr; Dioctyl phthalate: 15phr; 2,2,4-Trimethyl-1,2-dihydroquinoline Phenyl polymer: 3phr; Magnesium hydroxide: 70phr;

[0018] A method for producing high-temperature-resistant, flame-retardant, and oil-resistant rubber compound, the method is as follows:

[0019] The first step: use nitrile rubber and magnesium hydroxide to make masterbatch;

[0020] Step 2: Add zinc oxide, stearic acid, N-cyclohexyl-2-benzothiazole sulfenamide, carbon black, dioctyl phthalate, 2,2,4- Trimethyl-1,2-dihydroquinoline polymer is mixed to obtain a rubber compound;

[0021] The third step: adding dimorpholine disulfide and zinc diethyldithiocarbamate separately to the above mixed rubber to obtain the high tem...

Embodiment 2

[0023] High temperature resistant, flame retardant, oil resistant rubber compound, the formula is: nitrile rubber: 100phr; dimorpholine disulfide: 3phr; zinc oxide: 7phr; stearic acid: 3phr; N-cyclohexyl-2-benzothiazole Sulfenamide: 2phr; Zinc diethyldithiocarbamate: 4phr; Carbon black: 40phr; Dioctyl phthalate: 25phr; 2,2,4-Trimethyl-1,2-dihydroquinone Phenyl polymer: 6phr; Magnesium hydroxide: 100phr;

[0024] Production method is the same as embodiment one.

Embodiment 3

[0026] High temperature resistant, flame retardant, oil resistant rubber compound, the formula is: nitrile rubber: 100phr; dimorpholine disulfide: 2.5phr; zinc oxide: 6phr; stearic acid: 2.5phr; N-cyclohexyl-2-benzene Thiazole sulfenamide: 1.5phr; zinc diethyldithiocarbamate: 3.5phr; carbon black: 35phr; dioctyl phthalate: 20phr; 2,2,4-trimethyl-1,2 - dihydroquinoline polymer: 4.5phr; magnesium hydroxide: 85phr;

[0027] Production method is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com