High-temperature-resistant and scratch-resistant PI battery label material and preparation method thereof

A label material and high-temperature-resistant technology, applied in the field of film materials, can solve the problems of non-scratch-resistant and non-printable surfaces, achieve good temperature resistance, and improve the effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

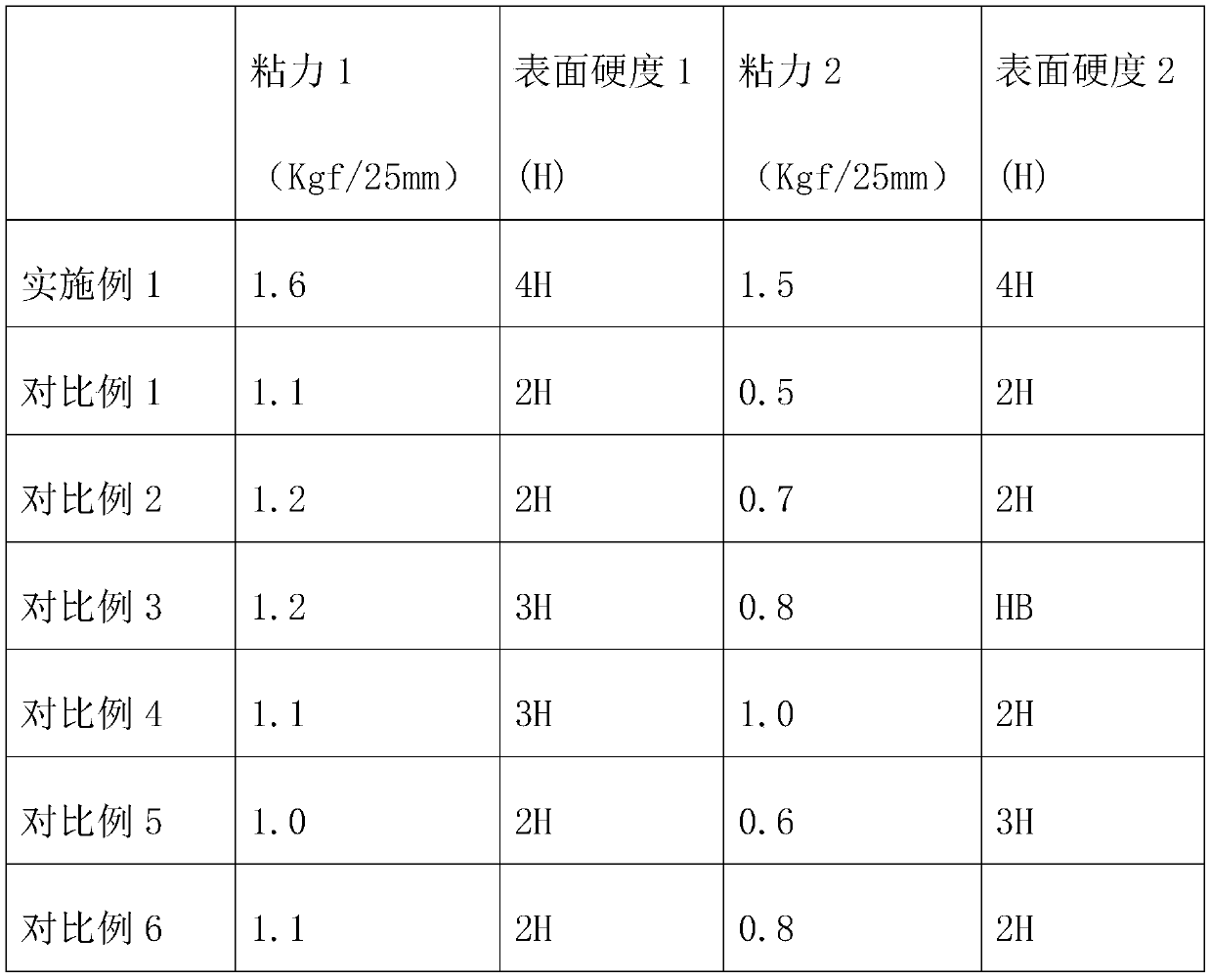

Examples

Embodiment 1

[0022] A method for preparing a high temperature and scratch-resistant PI battery label material, characterized in that it comprises the following steps:

[0023] (1) Synthesis of modified polyurethane resin, the first stage is to add reactive acrylamide, 2,6-dicarboxynaphthalene, acetic anhydride, and conduct chemical crosslinking reaction with polyurethane resin at 120 ° C; the second stage is the internal addition stage , the temperature is 200°C, the stirring speed is 120 rpm, until no acid is distilled out; the high temperature resistant glue is a commercially available epoxy resin high temperature resistant glue. The mass ratio of reactive acrylamide, 2,6-dicarboxynaphthalene, acetic anhydride, and polyurethane resin is 5:5-5.5:8-10:200. In the internal addition stage, the temperature is 200° C., and the stirring speed is 120 rpm.

[0024] (2) Use a stirring device to add the isocyanate hardener into the modified polyurethane resin and stir evenly, and the proportioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com