Halogen-free flame-retardant sheath material for class-1E K3 cable used for nuclear power station

A flame-retardant sheath, nuclear power technology, applied in the field of flame-retardant sheath materials for nuclear power cables, can solve the problems of thermal aging of cable sheath materials, unsatisfactory halogen-free flame-retardant performance, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

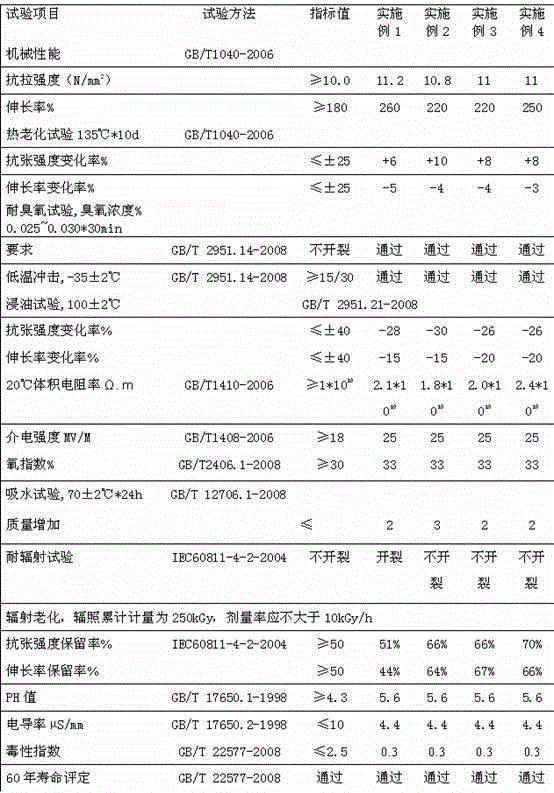

[0028] Embodiments 1 to 4: A halogen-free flame-retardant sheathing material for nuclear power 1E class K3 cables. The halogen-free flame-retardant sheathing material for nuclear power 1E class K3 cables consists of the following components in parts by weight, as shown in Table 1 Shown:

[0029] Example 1 Example 2 Example 3 Example 4 Ethylene-vinyl acetate copolymer 20 copies 25 copies 22 copies 24 copies Maleic anhydride grafted polyolefin 18 copies 12 copies 20 copies 15 copies Inorganic flame retardant 160 copies 150 copies 160 copies 170 copies Synergistic flame retardant 0 copies 3 copies 5 copies 5 copies Melamine Urate 15 copies 20 copies 25 copies 20 copies Microencapsulated red phosphorus 1 copy 2 copies 2 copies 2 copies antioxidant 4.5 servings 5 copies 6 servings 6 servings UV absorber 1.5 servings 0.8 parts 1.8 servings 1.2 parts Graphene a...

Embodiment 1

[0034] The inorganic flame retardant in embodiment 1 is magnesium hydroxide, the inorganic flame retardant in embodiment 2 is antimony trioxide, the inorganic flame retardant in embodiment 3 is magnesium hydroxide and antimony trioxide according to 1 : the mixture formed by 1, the inorganic flame retardant in embodiment 4 is nanometer montmorillonite.

[0035] The synergistic flame retardant in embodiment 1 is nano montmorillonite, the synergistic flame retardant in embodiment 2 is fumed silica, and the synergistic flame retardant in embodiment 3 is nano montmorillonite and gas phase The mixture formed in 1:1 in the method silica, the synergistic flame retardant in Example 4 is nano-montmorillonite.

[0036] The above antioxidants are tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 2-mercaptobenzimidazole zinc salt, 4,4'-thiobis (6-tert-butyl-3-methylphenol), at least one of dilauryl thiodipropionate.

[0037] The lubricant in Example 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com