Water-soluble non-combustible ceramic anti-radiation coating and preparation method thereof

An anti-radiation coating and water-soluble technology, applied in fire-resistant coatings, reflective/signal coatings, coatings, etc., can solve problems such as cracking and peeling of the coating layer, and achieve strong pressure resistance, controllable quality, and low thermal seepage coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Preparation of modified expandable graphite: Mix flake graphite, hydrogen peroxide and fuming nitric acid, and stir rapidly in an ice-water bath until the reaction is gentle. Acetic acid solution with a content ≥99.5% was stirred continuously, reacted for 60 minutes, washed with water, filtered with suction, and dried to obtain sulfur-free and ash-free modified expandable graphite with an expansion volume of 300-350ml / g, of which flake graphite, fuming nitric acid, The ratio of hydrogen peroxide and acetic acid is 5(g): 12(ml): 1(ml): 5(ml);

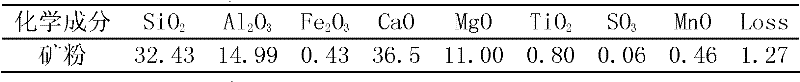

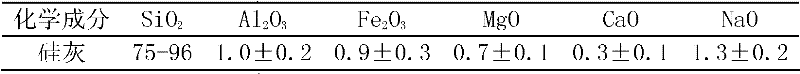

[0034] 2) Particle size control of each solid material: Grind mineral powder, silica fume, talc powder, mica powder, redispersible latex powder, hydroxyethyl methylcellulose, etc. until the particle size distribution is 10-40 μm, and the particles Smoother, less large grains and grains with sharp water chestnut;

[0035] 3) Preparation of water-soluble non-combustible ceramic anti-radiation coating: active material, inorganic fi...

Embodiment 2

[0039] 1) Preparation of modified expandable graphite: according to the mass ratio flake graphite: KMnO 4 =1:0.3 ratio to add KMnO to flake graphite 4 , stir well, add 70% HClO 3 solution, maintain a solid-to-liquid ratio of 1:4, keep at 35°C for 90 minutes with intermittent stirring, then wash with water, filter with suction, and dry to obtain modified expandable graphite with an expansion volume of 550ml / g;

[0040] 2) Particle size control of each solid material: grind mineral powder, silica fume, talc powder, mica powder, zinc-barium powder, redispersible latex powder, hydroxyethyl methylcellulose, etc. until the particle size distribution is within 10 ~40μm, the particles are smoother, and the large particles and particles with sharp water chestnuts are less;

[0041] 3) Preparation of water-soluble non-combustible ceramic anti-radiation coating: active material, inorganic filler, redispersible latex powder, hydroxyethyl methylcellulose, modified expandable graphite, wa...

Embodiment 3

[0043] 1) Preparation of modified expandable graphite: according to the mass ratio flake graphite: KMnO 4 =1:0.35 ratio to add KMnO to flake graphite 4 , stir well, add 70% HClO 3 solution, maintain a solid-to-liquid ratio of 1:4, keep at 35°C for 90 minutes with intermittent stirring, then wash with water, filter with suction, and dry to obtain modified expandable graphite with an expansion volume of 550ml / g;

[0044] 2) Particle size control of each solid material: grind mineral powder, silica fume, talc powder, mica powder, titanium dioxide powder, redispersible latex powder, hydroxyethyl methylcellulose, etc. until the particle size distribution is between 10 and 40μm, the particles are smoother, and there are fewer large particles and particles with sharp water chestnuts.

[0045] 3) Preparation of water-soluble non-combustible ceramic anti-radiation coating: active material, inorganic filler, redispersible latex powder, hydroxyethyl methylcellulose, modified expandable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com