X-ray excited luminescent anti-counterfeiting ink composition

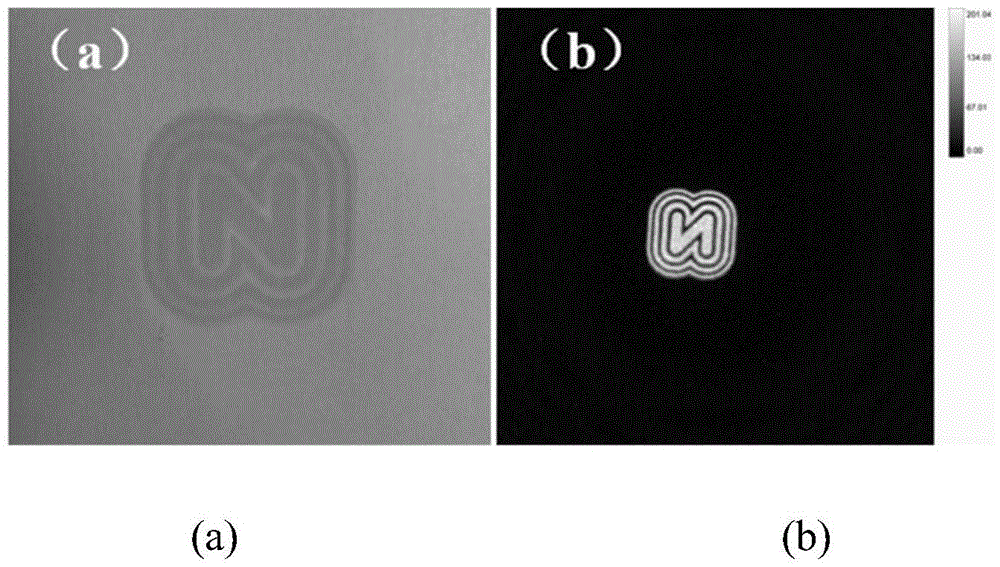

A technology of anti-counterfeiting ink and composition, applied in ink, household appliances, application and other directions, can solve the problems of difficult and high-end anti-counterfeiting, easy to obtain, etc., and achieve the effect of good anti-counterfeiting effect, good moisture resistance, and high difficulty in forgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

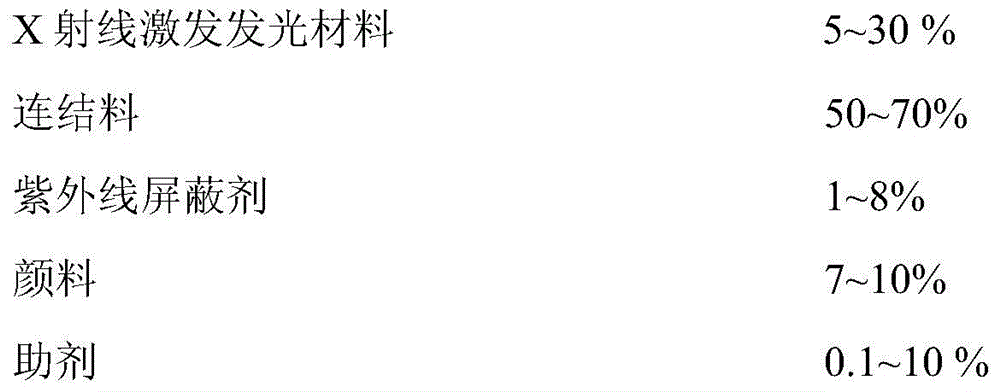

[0045] Offset printing ink: (percentage by weight)

[0046]

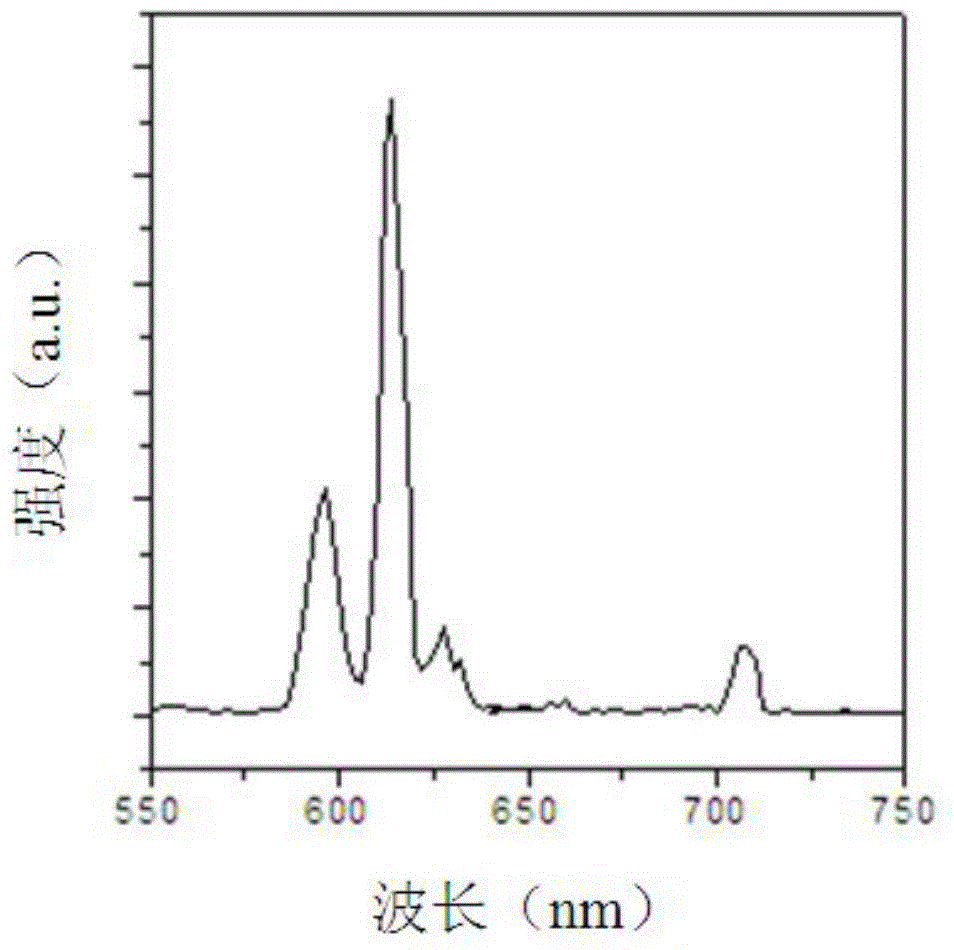

[0047] The X-ray excited luminescent powder is Eu:Lu 2 SiO 5

[0048] The components of the weight percentage of the binder:

[0049] (a) Resin 70%

[0050] (b) Solvent 10%

[0051] (c) Vegetable oil 20%

[0052] Resin is rosin modified phenolic resin

[0053] The solvent is 210# mineral oil;

[0054] The vegetable oil is linseed oil;

[0055] The pigment is FBB permanent red;

[0056] The UV-screening agent is phenyl o-hydroxybenzoate;

[0057] The auxiliary agent is polydimethylsiloxane;

[0058] Weigh the materials in the above proportions into the material barrel, mix them with a mixer for 30 minutes, and grind them on a three-roller mill until the product inspection reaches the technical index of offset printing ink application, then it is X-ray excited luminescent engraving gravure ink.

Embodiment 2

[0060]Engraving gravure ink:

[0061] Weight percent:

[0062]

[0063] The X-ray excited luminescent powder is Eu:Lu 2 SiO 5

[0064] The components of the weight percentage of the binder:

[0065] (a) Resin 5%

[0066] (b) Solvent 50%

[0067] (c) Vegetable oil 45%

[0068] Resin is rosin modified phenolic resin

[0069] The solvent is 210# mineral oil;

[0070] linseed oil

[0071] The pigment is permanent pink FR;

[0072] The UV-screening agent is phenyl o-hydroxybenzoate;

[0073] The auxiliary agent is polydimethylsiloxane;

[0074] Weigh the materials in the above proportions into the material barrel, mix them with a mixer for 30 minutes, and grind them on a three-roller mill until the product inspection reaches the application technical index of engraving gravure printing ink.

Embodiment 3

[0076] UV screen ink preparation:

[0077] Weight percent:

[0078]

[0079]

[0080] The X-ray excited luminescent powder is Eu:Lu 2 SiO 5

[0081] The components of the weight percentage of the binder:

[0082] (a) Resin 60%

[0083] (b) Solvent 40%

[0084] Resin is polyurethane resin

[0085] The solvent is; ethylene glycol ethyl ether acetate

[0086] The pigment is phthalocyanine blue BGS pigment;

[0087] The UV-screening agent is phenyl o-hydroxybenzoate;

[0088] The auxiliary agent is sodium dodecylbenzenesulfonate;

[0089] Weigh the materials in the above ratio into the material barrel, mix them with a mixer for 30 minutes, and filter through a 100-mesh screen. After the product is tested to meet the technical indicators of screen ink application, it will be UV-curable blue X-ray excited luminescent screen ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com