Construction method for connecting natural gas pipelines with gas

A construction method and natural gas technology, applied in the direction of pipe/pipe joint/pipe fitting, pipe laying and maintenance, non-removable pipe connection, etc., can solve the problem of no gas connection method, and achieve good economic and social benefits. , the effect of low labor consumption and less preparation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

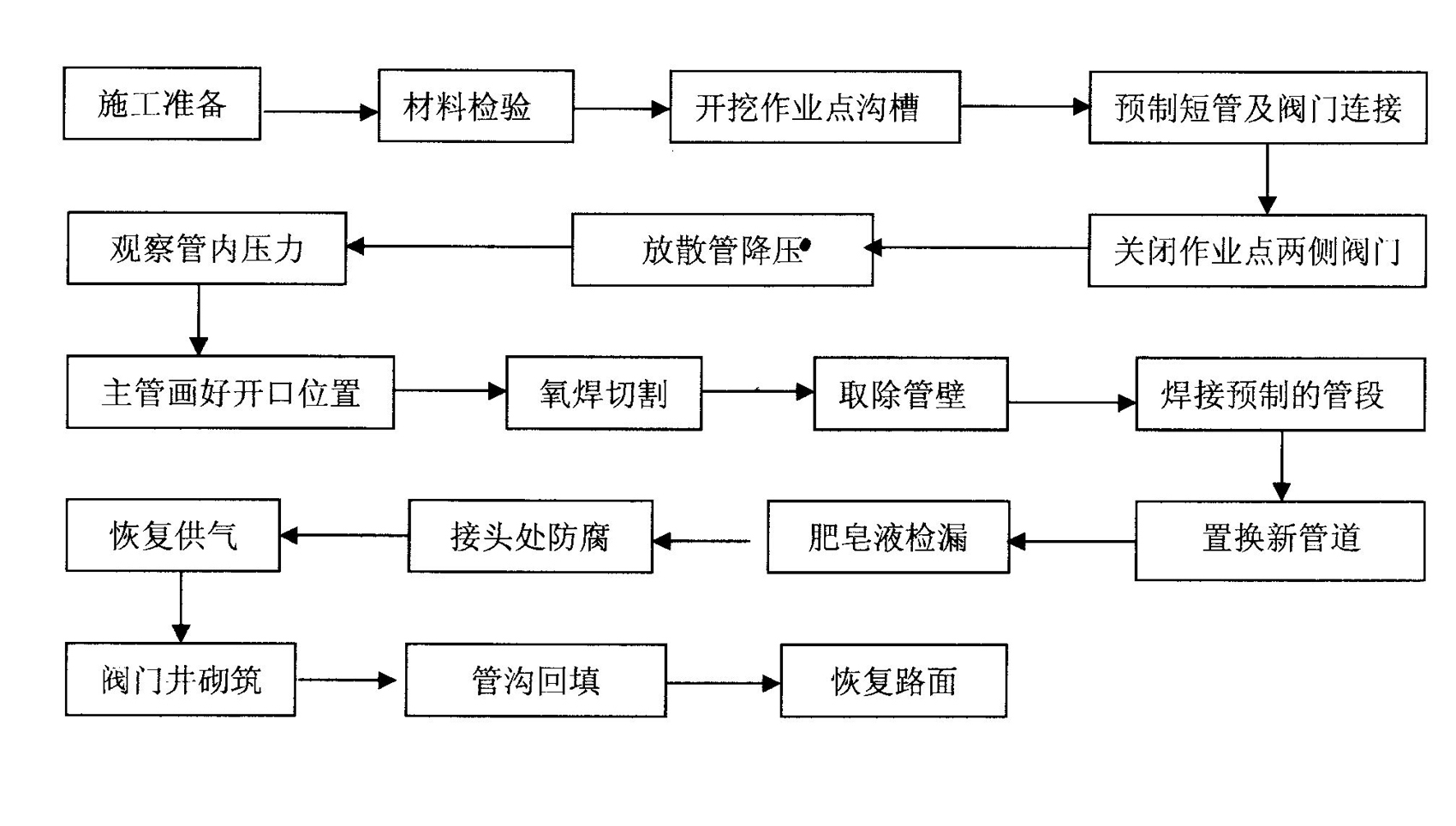

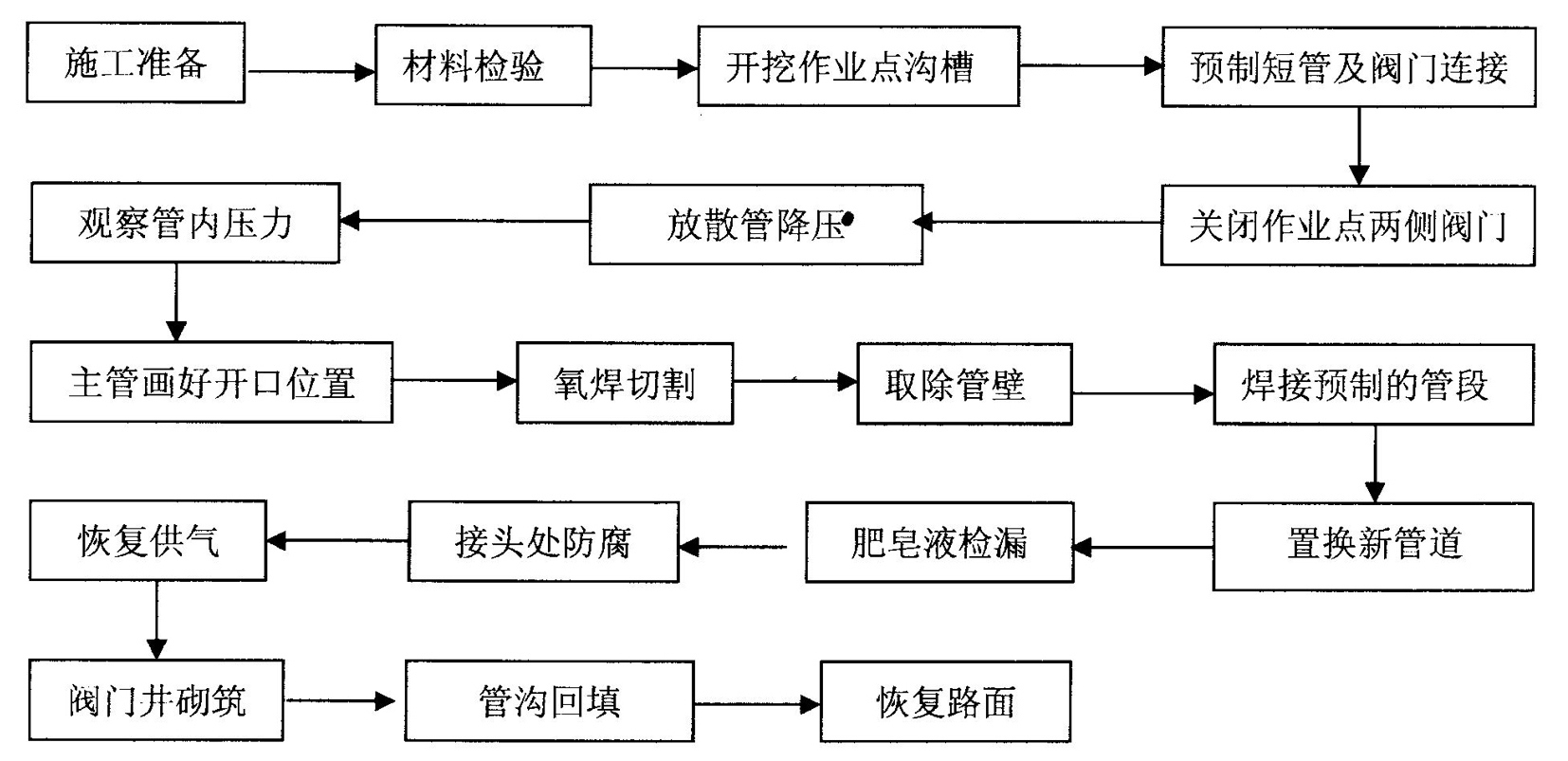

[0016] Concrete embodiment 1: the construction method of decompression method with gas connection

[0017] Tee connection: When the connecting branch pipe is smaller than the original main pipe, the connecting pipe is generally a short flange pipe or a valve connected to the short flange pipe.

[0018] Trench for excavation work: Check the distance and relative position between the new pipe and the existing pipe. For ease of operation, the net distance between the pipe and the trench wall shall not be less than 0.8m, and the net distance from the trench bottom shall not be less than 0.5m. A valve well is built behind the gas connection to protect the rear valve.

[0019] Preparation work: close the valves at the two sections of the operation point or the main valve of the pressure regulating cabinet, set up a temporary relief pipe, check whether the valve in the valve well is working normally, check the gas pressure detection point set up on the operation site, and set up a s...

specific Embodiment 2

[0038] Specific embodiment 2: The construction method of connection with gas without depressurization method

[0039] Suitable for medium and low pressure natural gas pipelines with gas connections. That is, the gas pressure of the original gas pipeline does not decrease, and the pressure is about 300Pa. Drill a hole on the original main pipe with an air drill. When the branch pipe is less than 80mm, tap the thread after drilling the hole and connect it with a screw. When the branch pipe is larger than 80mm, the welding form should be adopted, and the operation procedure is the same as that of the depressurization method.

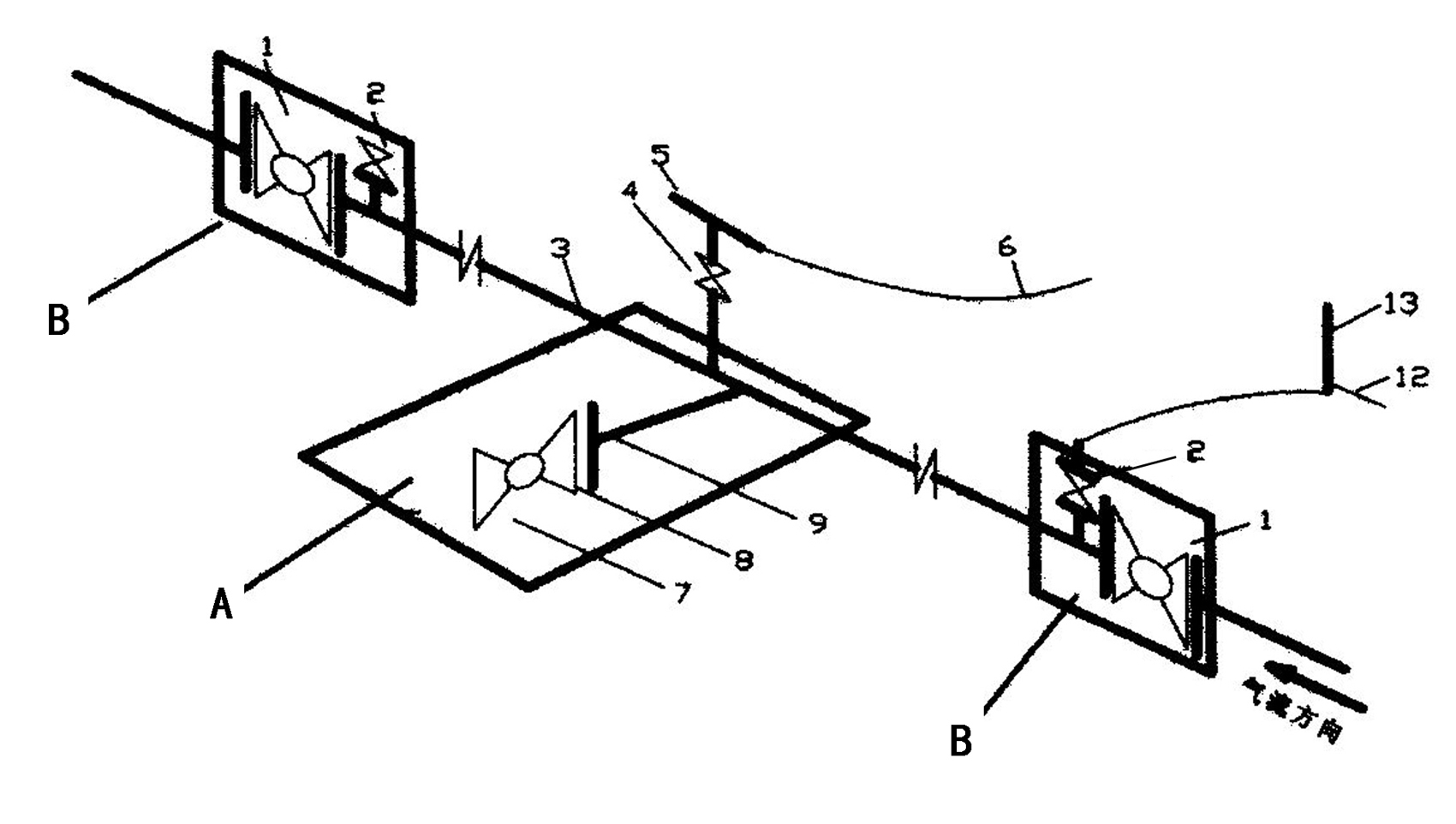

[0040] The construction equipment of the present invention with a gas takeover operation point:

[0041] serial number

[0042] The labor force organization of the operating point with the gas connection pipe of the present invention:

[0043] serial number

[0044] Equipment and materials required for construction of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com