Digital printing process for wool fabric

A digital printing and process technology, applied in the field of wool fabric digital printing process, can solve the problems of light color of printed fabrics, difficult operation control, unevenness, etc., and achieve high color fastness and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Enzyme treatment: protease 1.0g / L, temperature 50°C, time 30min, pH 8.0;

[0057] (2) Acid pulp: the acid pulp includes: 2% sodium alginate, 7% urea, 5% sodium bisulfite, 3% ammonium sulfate and 1% penetrant;

[0058] (3) Spray printing, drying, the drying temperature is 60°C, and the drying time is 3 minutes;

[0059] (4) Steam for 60 minutes, rinse with cold water below 30°C, and wash with warm water at 40°C;

[0060] (5) Soaping at 80°C, the soaping solution includes 2g / L disodium hydrogen phosphate and 3g / L soap flakes, and adjust the pH value of the soaping solution to 9 with ammonia water;

[0061] (6) Wash in warm water at 40°C, cold water below 30°C, and dry.

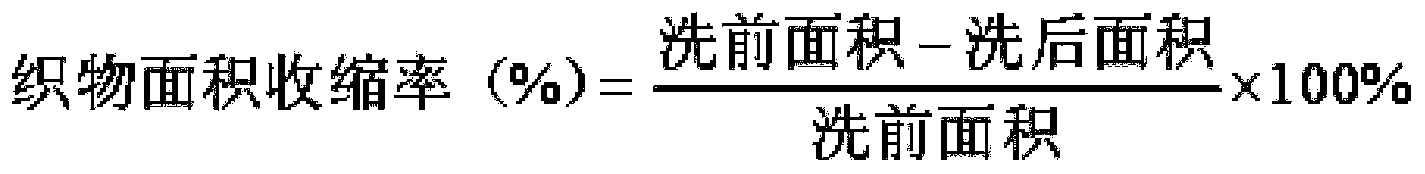

[0062]The properties after enzyme treatment are: whiteness 64.23, shrinkage rate 4.86%, warp strength 342.5N; K / S value after printing 97.593, dry and wet rubbing fastness 4-5, 4; soaping fastness Color: 4.

Embodiment 2

[0064] (1) Enzyme treatment: protease 0.5g / L, temperature 50°C, time 60min, pH 8.0;

[0065] (2) Acid pulp: the acid pulp includes: 1% sodium alginate, 10% urea, 3% sodium bisulfite, 6% ammonium sulfate and 0.5% penetrant;

[0066] (3) Spray printing, drying, the drying temperature is 70°C, and the drying time is 2 minutes;

[0067] (4) Steam for 50 minutes, rinse with water at 30°C, and wash with warm water at 55°C;

[0068] (5) Soaping at 70°C, the soaping solution includes 4g / L disodium hydrogen phosphate and 1g / L soap flakes, and adjust the pH value of the soaping solution to 9.5 with ammonia water;

[0069] (6) Wash in warm water at 55°C, cold water at 35°C, and dry.

[0070] The properties after enzyme treatment are: whiteness 64.10, shrinkage rate 4.64%, warp strength 340.5N; K / S value after printing 95.482, dry and wet rubbing fastness 4-5, 4; soaping fastness Color: 4.

Embodiment 3

[0072] (1) Enzyme treatment: protease 1.5g / L, temperature 45°C, time 60min, pH 8.5;

[0073] (2) Acid pulp: the acid pulp includes: 4% sodium alginate, 5% urea, 8% sodium bisulfite, 1% ammonium sulfate and 1.5% penetrant;

[0074] (3) Spray printing, drying, the drying temperature is 45°C, and the drying time is 6 minutes;

[0075] (4) Steam for 70 minutes, rinse with cold water at 35°C, and wash with warm water at 55°C;

[0076] (5) Soaping at 90°C, the soaping solution includes 1g / L disodium hydrogen phosphate and 6g / L soap flakes, and adjust the pH value of the soaping solution to 8.5 with ammonia water;

[0077] (6) Wash with warm water at 40°C, cold water at 30°C, and dry.

[0078] The properties after enzyme treatment are: whiteness 61.85, shrinkage rate 4.82%, warp strength 341.4N; K / S value after printing 92.681, dry and wet rubbing fastness 4-5, 4; soaping fastness Color: 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com