Preparation method for preparing sodium copper chlorophyllin from gingko leaves

A technology of copper chlorophyllin sodium salt and chlorophyllin cupric acid, which is applied in the field of preparing copper chlorophyllin sodium salt from ginkgo leaves, can solve the problems of high cost and low purity, achieve stable quality, high purity, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

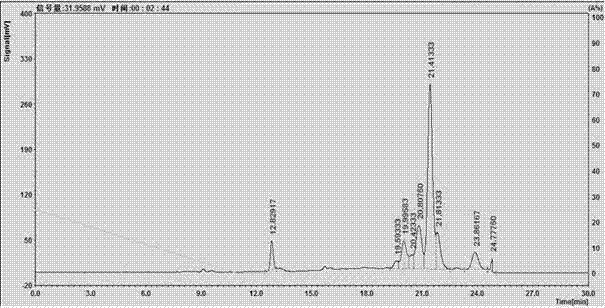

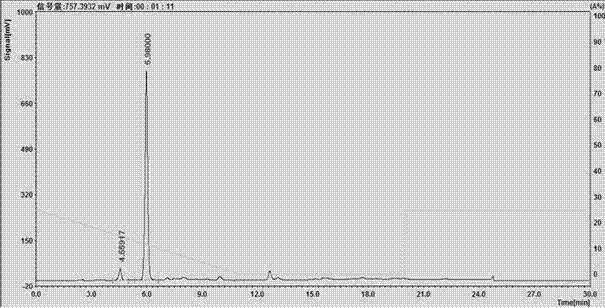

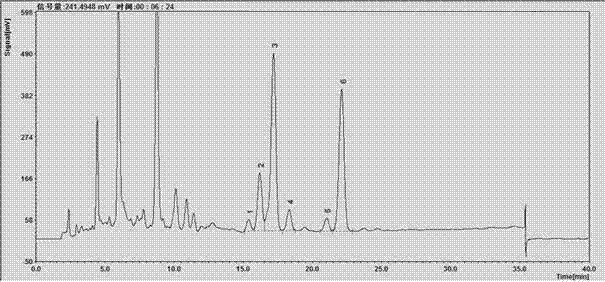

[0042]Take 0.5Kg of dried ginkgo leaves, analyze by liquid phase and contain 0.3% pheophytin, crush them, add 1.5L of No. 6 solvent oil and soak at 30°C for 1 hour, filter, and rinse the filter residue with 1L of No. 6 solvent oil; the extract Contain 1.35g of pheophytin by liquid phase analysis; concentrate the extract to 20% of the mass of Ginkgo biloba leaves, add 200mL of 80% isopropanol, 200mL of No. 6 solvent oil, shake well, transfer to a brown 1000mL jar, place In a water bath at 60°C, add 32mL of 30% (w / w) liquid caustic soda, 16mL of 20% (w / w) copper sulfate aqueous solution, shake well and let stand to saponify 0.5% of the water; Stand in the separatory funnel for stratification; discard the middle layer and the upper layer, transfer the lower layer to a continuous liquid-liquid extractor, and use No. 6 solvent oil to extract the oil-soluble impurities until the effluent of No. 6 solvent oil is light in color; remove the lower layer of soap Add 400mL of No. 6 solven...

Embodiment 2

[0045] Take 0.5Kg of dried Ginkgo biloba leaves, analyze by liquid phase and contain 0.3% pheophytin, pulverize, add 1.5L of 60% ethanol, 1.5L of No. 6 solvent oil, stir and extract at 45°C for 4 hours, let it stand for stratification, and replenish the lower layer. Add 1.5L of No. 6 solvent oil, stir for 30 minutes, and then let stand to separate layers; combine the No. 6 solvent oil phase to obtain the pheophytin extract; this extract contains 1.41g of pheophytin through liquid phase analysis; concentrate the extract to 45% of the mass of ginkgo leaves, add 200mL of 90% isopropanol, 200mL of No. 6 mineral spirits, shake well, transfer to a brown 1000mL wide-mouth bottle, put it in a water bath at 50°C, and add 32mL of 30% (w / w) liquid caustic soda , 16 mL of 20% (w / w) copper sulfate aqueous solution, shake well and let stand to saponify 2 hours of water; add 400 mL of water to the soap solution, transfer it into a well-protected separatory funnel and let it stand for stratifi...

Embodiment 3

[0048] Take 0.5Kg of dried Ginkgo biloba leaves, analyze by liquid phase and contain 0.3% pheophytin, crush them, add 1.5L of No. 6 solvent oil, let stand and soak at 60°C for 6 hours, filter, and wash the filter residue with 1L of No. 6 solvent oil; The extract was analyzed by liquid phase to contain 1.37g of pheophytin; concentrate the extract to dryness, add 100% isopropanol 100mL, No. 6 solvent oil 200mL, shake well, transfer to a brown 1000mL wide-mouth bottle, put in a 40°C water bath Add 32mL of 30% (w / w) liquid caustic soda, 16mL of 20% (w / w) copper sulfate aqueous solution, shake well and let stand for saponification for 20 hours; add 200mL of water to the soap solution and transfer it into a well-protected separatory funnel Leave to stand for stratification; discard the middle layer and the upper layer, transfer the lower layer to a continuous liquid-liquid extractor, and extract the oil-soluble impurities with No. 6 solvent oil until the effluent of No. 6 solvent oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com