Preparation method and application of wheel sticking prevention emulsified asphalt for sticky layers

A technology of emulsified asphalt and sticky wheel, which is applied in the direction of building components, building insulation materials, building structures, etc., can solve the problems of low-temperature performance defects of non-sticky wheel emulsified asphalt, the performance impact of the preparation method, etc., and achieve low glass transition temperature, Effect of improving low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

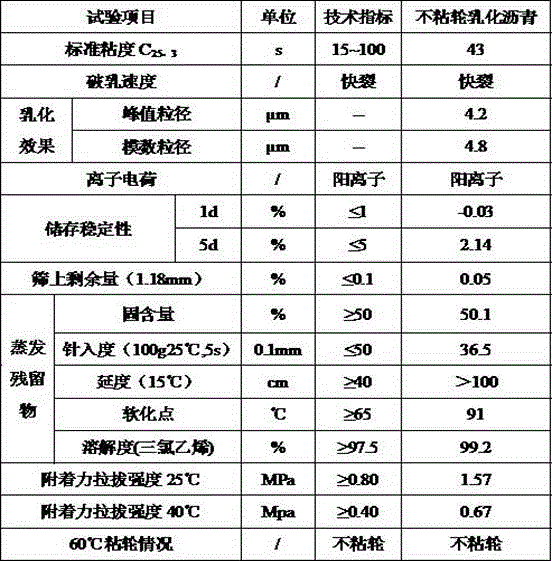

Embodiment 1

[0024] The preparation method of non-stick wheel emulsified asphalt for adhesive layer of the present invention, the steps are as follows:

[0025] 1) Take 490g of 70# petroleum asphalt and add 5g of SBS with a styrene content of 45% and a melting point of 110 o C polyethylene wax 2g, commercially available middle road WM-4198 asphalt viscosity reducer 3g, sulfur 0.2g at 160 o The modified asphalt was prepared by high-speed shearing at C temperature for 1 h. Heat modified asphalt to 170 o C heat preservation stand-by.

[0026] 2) Take 4g of commercially available Zhonglu EB-2212 sticky layer emulsifier and 3g of sodium carboxymethyl cellulose, add water to 492g at 45 o Keep warm at C temperature for later use.

[0027] 3) Add the soap liquid to the soap liquid tank in the German DT colloid mill at 45 o C temperature insulation, the modified asphalt is added to the asphalt tank in the colloid mill, at 170 o Keep warm in C, turn on the colloid mill, increase the speed of t...

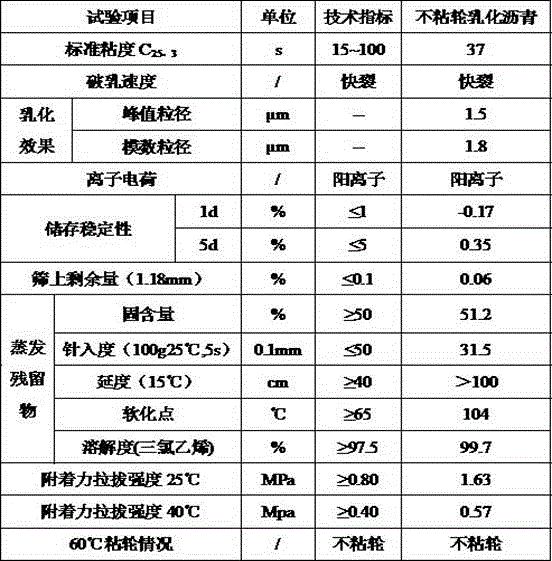

Embodiment 2

[0032] The preparation method of non-stick wheel emulsified asphalt for adhesive layer of the present invention, the steps are as follows:

[0033] 1) Take 500g of 90# petroleum asphalt and add 5g of SBR with a styrene content of 53% and a melting point of 101 o C polyethylene wax 7g, commercially available Meide DAT viscosity reducer 5g, Vita linking agent 3g at 160 o In the case of C, the modified asphalt was prepared by high-speed shearing for 1 hour. Put the modified asphalt at 160 o C heat preservation stand-by.

[0034] 2) Take 5g of commercially available Meide AA-57 sticky layer emulsifier and hydroxyethyl cellulose, add water to 480g 50 o C heat preservation stand-by.

[0035] 3) Add the soap to the soap tank in the ENH modified asphalt colloid mill at 50 o Insulation under C, the modified asphalt is added to the asphalt tank in the colloid mill, at 160 oKeep warm in C, turn on the colloid mill, increase the speed of the grinding head to 6000r / min, and then emul...

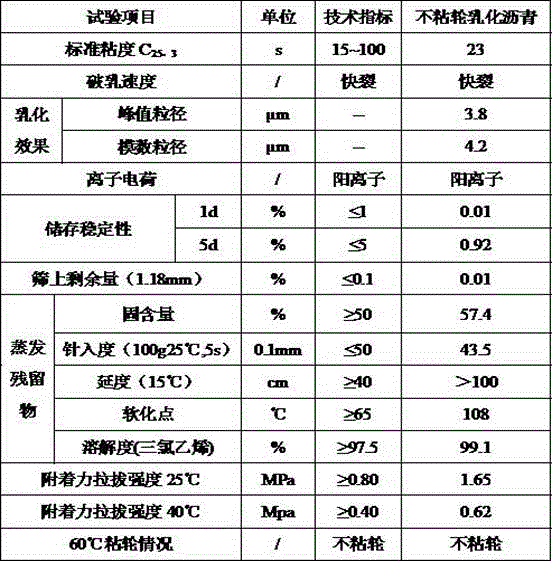

Embodiment 3

[0040] The preparation method of non-stick wheel emulsified asphalt for adhesive layer of the present invention, the steps are as follows:

[0041] 1) Take 550g of 90# petroleum asphalt and add 3g of SEBS with a styrene content of 48% and a melting point of 138 o C polyethylene wax 4g, commercially available Meide M-1 viscosity reducer 2g, Vita linker 2g at 160 o In the case of C, the modified asphalt was prepared by high-speed shearing for 1 hour. Modified asphalt at 180 o C heat preservation stand-by.

[0042] 2) Take 8g of commercially available Meide DF-62E sticky layer emulsifier and 3g of hydroxypropyl cellulose, add water to 437g 60 o C heat preservation stand-by.

[0043] 3) Add the soap solution to the soap solution tank in the ENH modified asphalt colloid mill at 60 o Insulation under C, the modified asphalt is added to the asphalt tank in the colloid mill, at 180 o Keep warm in C, turn on the colloid mill, increase the speed of the grinding head to 30000r / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com