SBS modified emulsifying asphalt and preparation process thereof

A technology of emulsified asphalt and modification, applied in building components, building insulation materials, buildings, etc., can solve the problems of unqualified emulsified asphalt, cumbersome methods, difficult to modify asphalt, etc., reduce production difficulty, improve high temperature performance, and resist Good permanent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Composition formula of SBS modified emulsified asphalt:

[0053] Base bitumen (%) 57

[0054] SBS modifier (%) 1.8

[0055] Sasobit (Sasobit) (%) 0.9

[0056] WD-3#(%) 0.3

[0057] 63℃ hot water (%) 37.85

[0058] Cationic emulsifier MQK-1M 1.6

[0060] Polyvinyl alcohol 0.15

[0061] SBS emulsified asphalt preparation method:

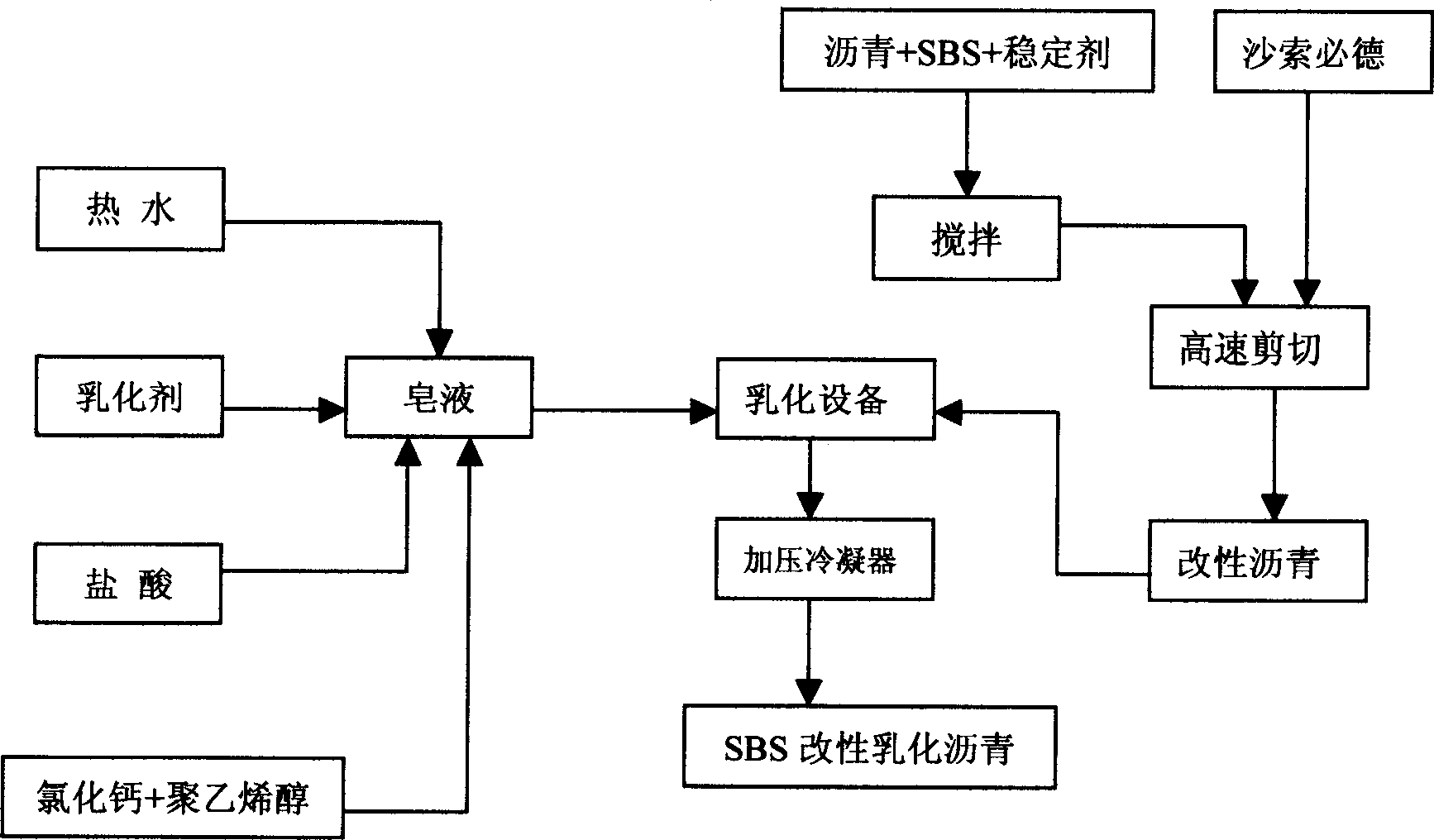

[0062] According to the composition formula, adopt figure 1 The process flow diagram is carried out, the first stage:

[0063] a) Heat base asphalt to 185°C, add SBS modifier, and stir for 20 minutes.

[0064] b) Add Sasobit (Sasobit), cut by high-speed shear for 1.5 hours, add WD-3# to react for 15 minutes.

[0065] second stage:

[0066] c) Add an emulsifier to hot water at 63°C, then add hydrochloric acid to adjust the pH to 1.8, and stir evenly until the liquid is transparent.

[0067] d) adding calcium chloride and polyvinyl alcohol to the above solution to obtain a soap solution.

[0068] e) Put t...

Embodiment 2

[0077] Composition formula of SBS modified emulsified asphalt:

[0078] Base pitch (%) 56.7

[0079] SBS modifier (%) 2.1

[0080] Sasobit (Sasobit) (%) 0.9

[0081] WD-3# stabilizer (%) 0.3

[0082] 65℃ hot water (%) 37.85

[0083] Cationic emulsifier MQK-MQ3 1.6

[0085] Polyvinyl alcohol 0.15.

[0086] SBS emulsified asphalt preparation method:

[0087] According to the composition formula, adopt figure 1 The process flow diagram is carried out, the first stage:

[0088] a) Heat base asphalt to 190°C, add SBS modifier, and stir for 20 minutes.

[0089] b) Add Sasobit (Sasobit), cut by high-speed shear for 1.5 hours, add WD-3# to react for 15 minutes.

[0090] second stage:

[0091] c) Add an emulsifier to hot water at 65°C, then add hydrochloric acid to adjust the pH value to 2.0, and stir evenly until the liquid is transparent.

[0092] d) adding calcium chloride and polyvinyl alcohol to the above solution to obtain a soap solution...

Embodiment 3

[0099] Composition formula of SBS modified emulsified asphalt: weight percentage

[0100] Base bitumen 54.9

[0101] SBS modifier 1.6

[0102] Sasobit 1.2

[0103] WD-3# 0.3

[0104] 62℃ hot water 39.85

[0105] Cationic emulsifier Redicote@-C-450 1.6

[0106] Calcium chloride 0.4

[0107] Polyvinyl alcohol 0.15.

[0108] SBS emulsified asphalt preparation method:

[0109] According to the composition formula, adopt figure 1 The process flow diagram is carried out, the first stage:

[0110] a) Heat base asphalt to 180°C, add SBS modifier, and stir for 20 minutes.

[0111] b) Add Sasobit (Sasobit), cut by high-speed shear for 1.5 hours, add WD-3# to react for 15 minutes.

[0112] second stage:

[0113] c) Add an emulsifier to hot water at 62°C, then add hydrochloric acid to adjust the pH to 1.8, and stir evenly until the liquid is transparent.

[0114] d) adding calcium chloride and polyvinyl alcohol to the above solution to obtain a soap solution.

[0115] e) Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com