An extended conical lapping extrusion mechanism

A fine grinding and conical technology, applied in the direction of embossing/polishing soap, molding soap, etc., can solve the problems of large difference in crystal phase structure, insufficient refinement and uniformity of soap particles, low transparency of soap particles, etc. Improve the effect of refining, good effect and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

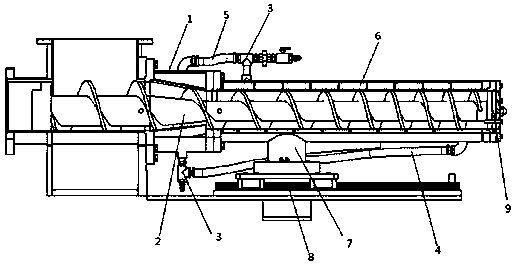

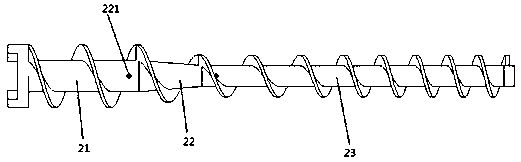

[0025] Such as Figure 1-3 The shown elongated conical lapping extrusion mechanism includes a barrel 1 and a screw 2 fixedly installed inside the barrel 1. The barrel 1 includes a large-diameter barrel 11 and a conical barrel 12 from left to right. and small-diameter barrel 13, the screw 2 includes a large-diameter screw 21, a conical screw 22, and a small-diameter screw 23 from left to right, and is installed on the large-diameter barrel 11, conical barrel 12, and small-diameter barrel respectively. 13, the lower end of the tapered cylinder 12 is provided with a water inlet A 121, the upper end is provided with a water outlet A 122, the front lower end of the small-diameter cylinder 13 is provided with a water inlet B 131, and the upper end is provided with a water outlet B 132, The water inlet A121 and the water inlet B131 are fixedly connected through the three-way valve 3 and the water inlet pipe 4, the water outlet A122 and the water outlet B132 are fixedly connected thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com