Manual soap embossing device

The technology of soap printing and limit hole is applied in the field of manual soap printing devices, which can solve the problems of large deformation, unsightly appearance, and different depths of characters and images in hand soap, and achieve the effect of good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

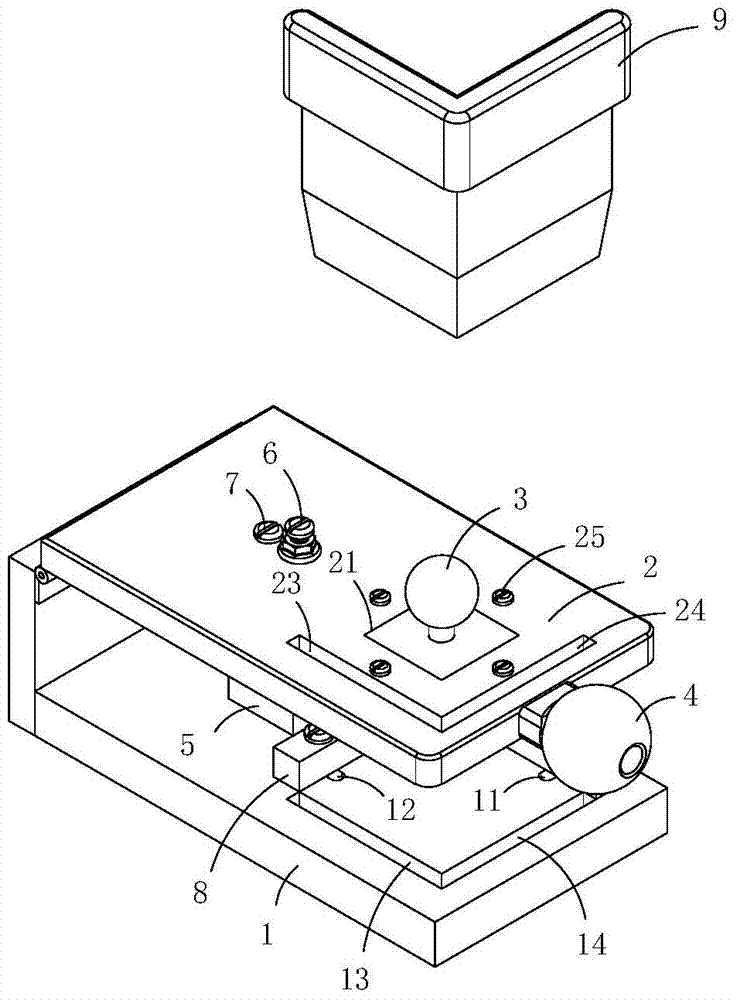

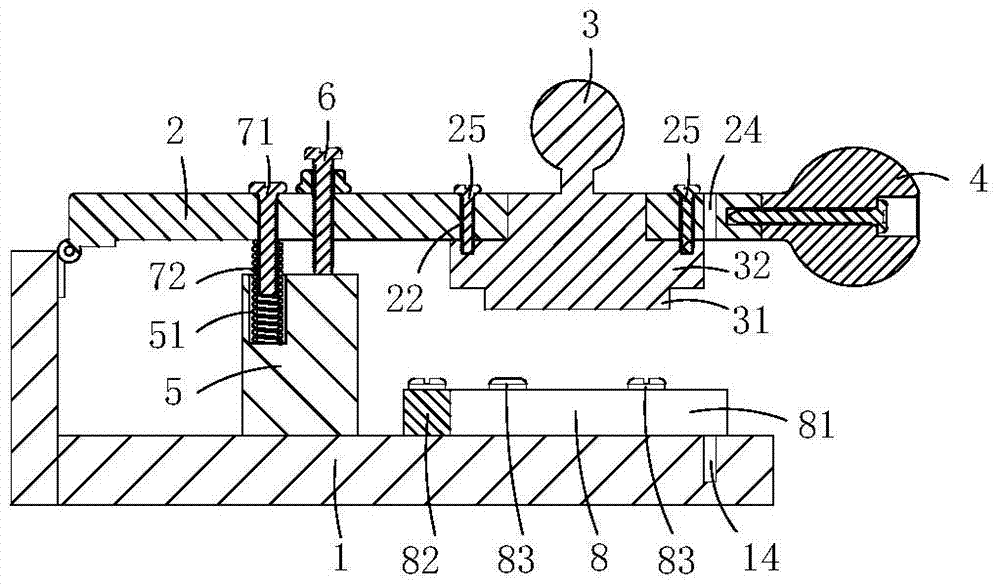

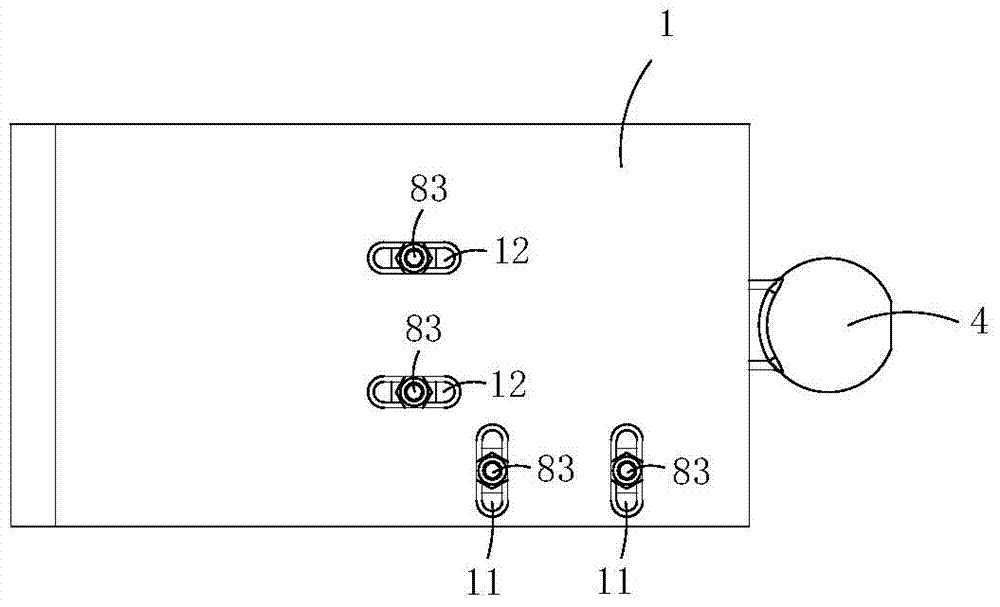

[0012] This embodiment is a manual soap printing device, see Figure 1 to Figure 5 As shown, it includes a base 1, a pressing plate set on the base to rotate, a soap stamp 3 fixed on the pressing plate, a handle 4 that drives the pressing plate to rotate, a limit boss 5 set on the base, and an adjusting bolt set on the pressing plate 6. The reset mechanism 7, the position adjustment mechanism 8, and the cutter 9; the bottom end of the adjusting bolt extends downward from the pressure plate, and when the pressure plate rotates to the lowest position, it abuts on the limiting boss.

[0013] The reset mechanism includes a reset limit post 71 set on the pressure plate and a return spring 72 sleeved on the reset limit post. The bottom end of the reset limit post extends downwards from the pressure plate, and the return spring is sleeved in the direction of the reset limit post. On the part of the column protruding downward from the pressing plate; a sliding hole 51 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com