Soap impressing device and use method

A soap and fixing frame technology, applied in the direction of embossing/polishing soap, etc., can solve the problems of affecting the use of stampers, poor embossing effect, low production efficiency, etc., saving time, good embossing effect, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

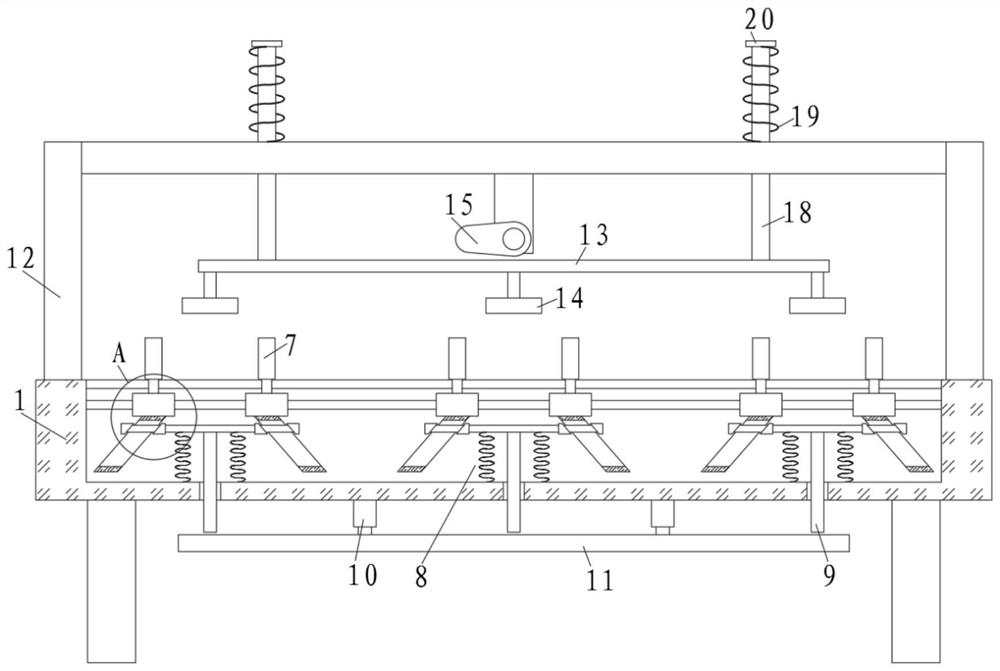

[0037] A soap embossing device, comprising a fixed frame 1, the fixed frame 1 is provided with multiple sets of fixing mechanisms, and the fixing mechanism includes a slider 2, an inclined plate 3, a horizontal plate 4, a through groove 5, a long plate 6, a splint 7, a second a spring 8;

[0038] The top of the fixed frame 1 is slidingly connected with multiple sets of matching sliders 2, and the bottom of the slider 2 is fixedly provided with a matching swash plate 3, and the inside of the swash plate 3 is provided with a through groove 5, and the swash plate 3 passes through the through groove 5 is slidably connected with a horizontal plate 4, and the horizontal plate 4 is fixedly provided with matching long plates 6 on both sides of the inclined plate 3, and a first spring 8 is fixedly provided between the bottom of the horizontal plate 4 and the inner bottom end of the fixed frame 1, and the sliding The top of the block 2 runs through the fixing frame 1 and is fixedly conn...

Embodiment 2

[0054] On the basis of embodiment 1,

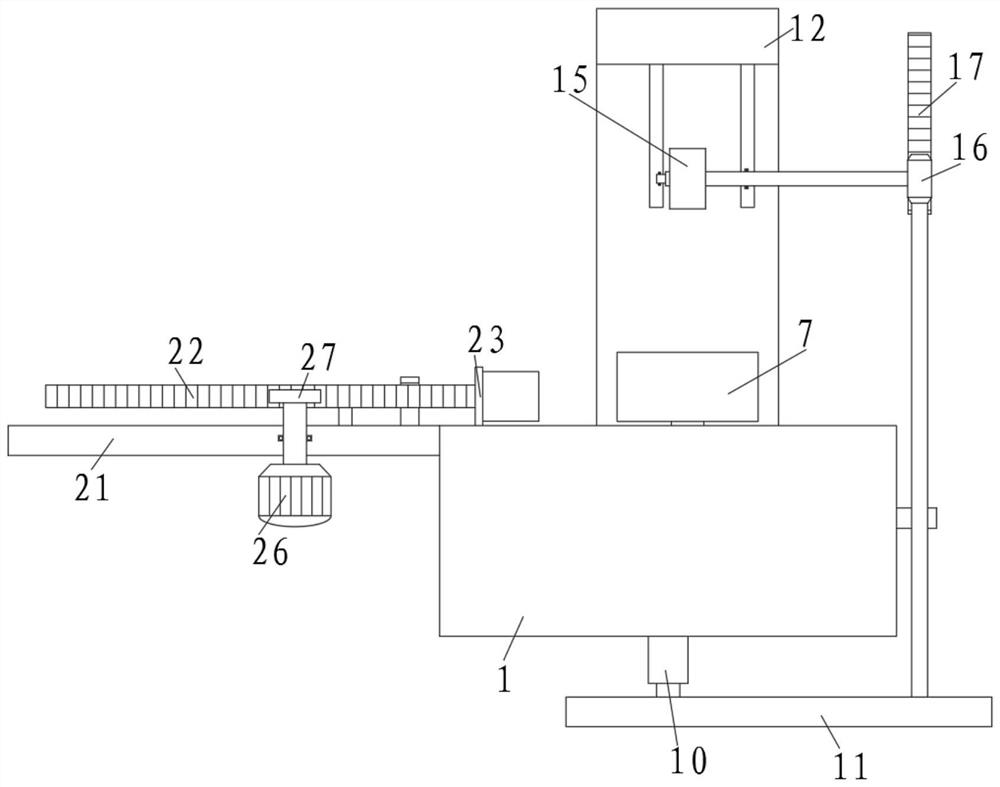

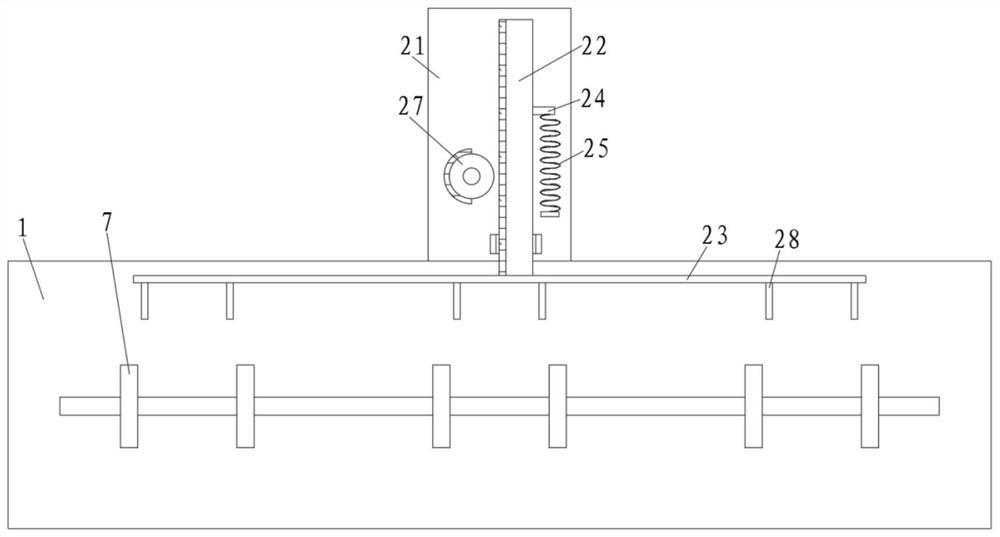

[0055] One end of the fixed frame 1 is also provided with a feeding mechanism, and the feeding mechanism includes a side plate 21, a tooth plate 22, a feeding plate 23, a motor 26, a half gear 27, and a baffle plate 28;

[0056] One end of the fixed frame 1 is fixedly provided with a side plate 21, and the top of the side plate 21 is slidably connected with a tooth plate 22, and one end of the tooth plate 22 close to the splint 7 is fixedly provided with a feed plate 23, and the feed plate 23 is fixedly provided with multiple groups of splints 7. Corresponding to the baffle plate 28 , a motor 26 is mounted on the bottom of the side plate 21 , and the output end of the motor 26 is connected with a half gear 27 meshing with the gear plate 22 .

[0057] Both the top of the side plate 21 and the side of the tooth plate 22 are fixedly provided with a fixing block 24 , and a third spring 25 is fixedly arranged between the two sets of fixing blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com