Soap embossing device

A soap and holder technology, applied in the direction of embossing/polishing soap, etc., can solve the problems of reduced production efficiency, inconvenient operation, complex structure, etc., and achieve the effects of convenient operation, high embossing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

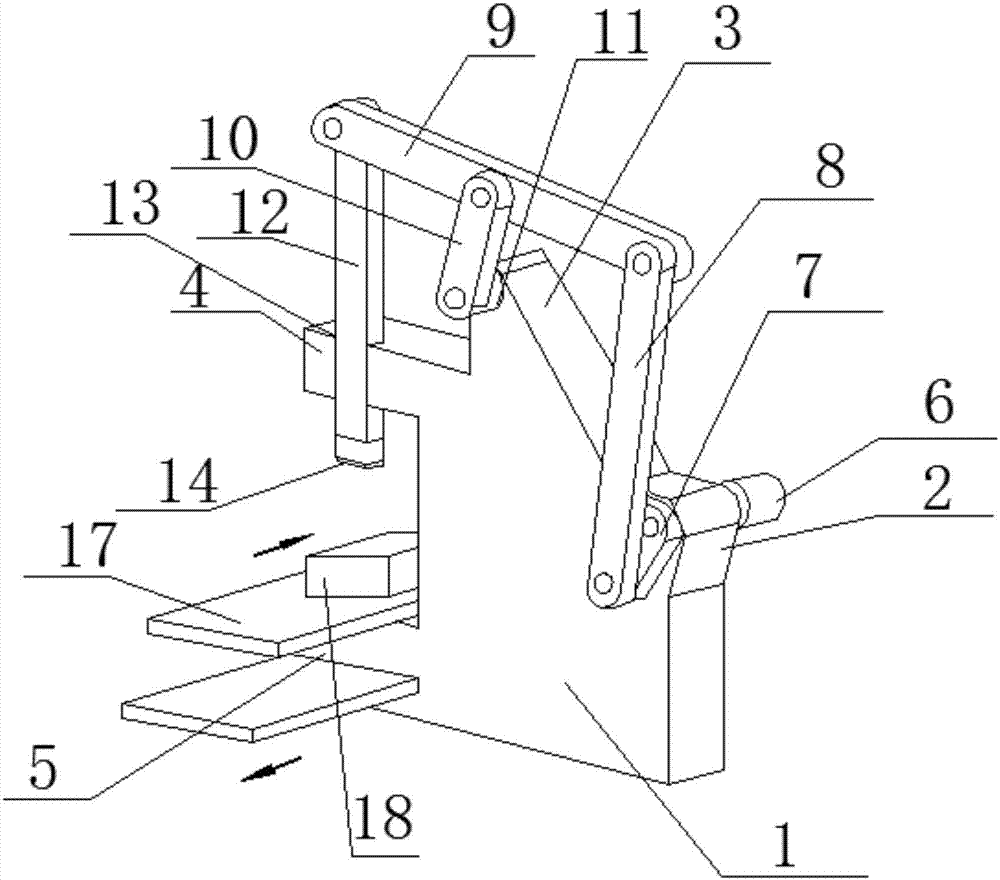

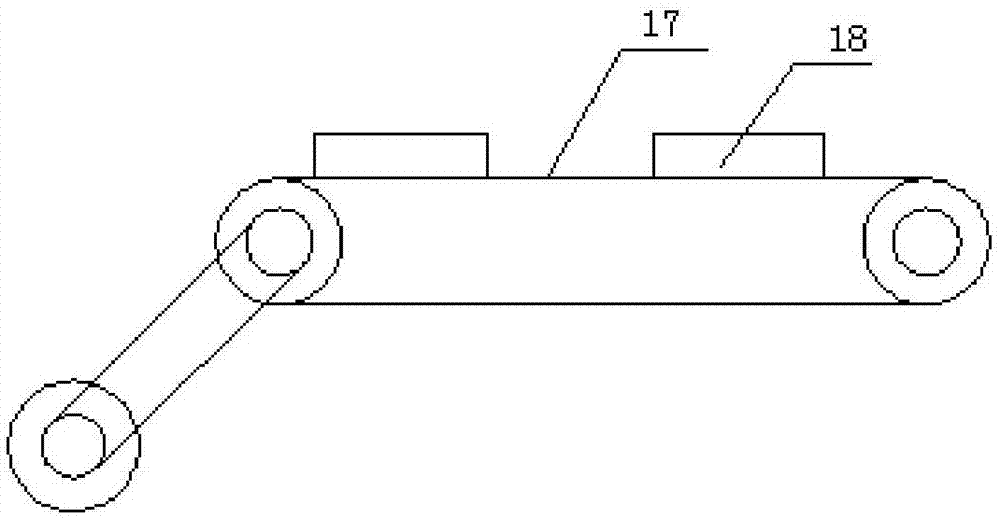

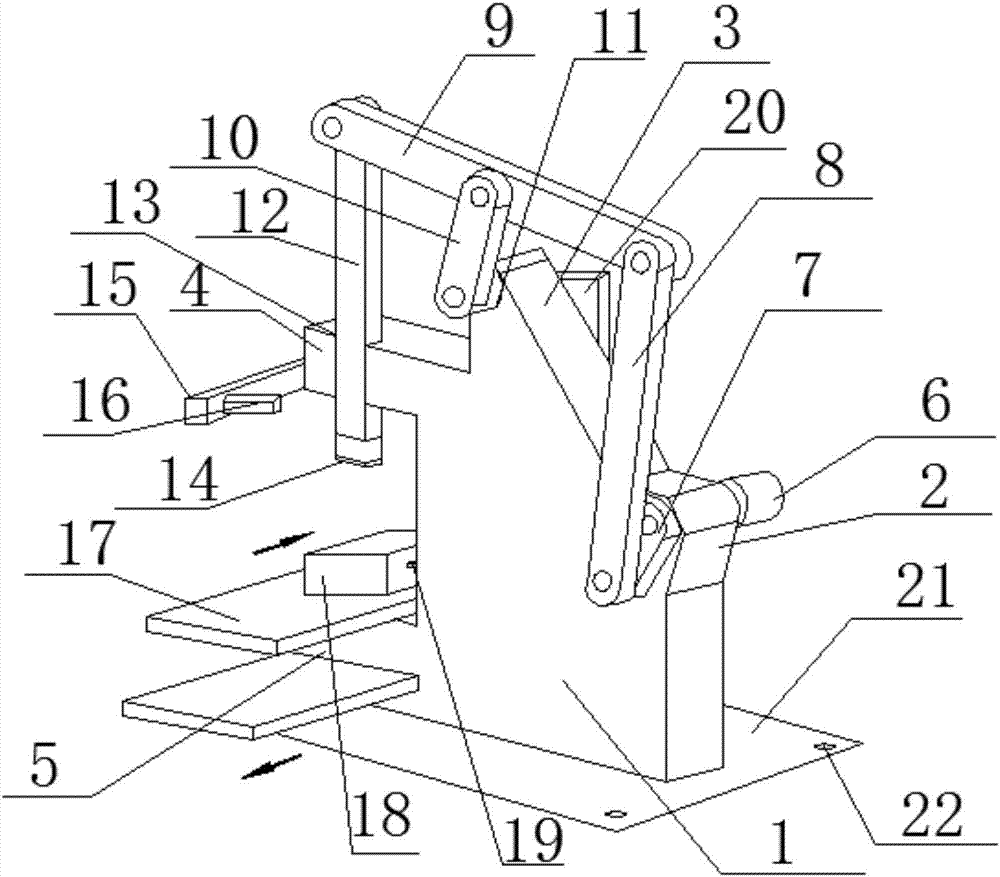

[0024] figure 2 , image 3 and Figure 4 Show the specific embodiment of the present invention: a kind of soap embossing device, comprise fixed seat 1 and conveying mechanism, described conveying mechanism comprises conveyer belt 17, the upper end of described fixed seat 1 is provided with extension plate 4, and the lower end is provided with spacer plate 5. A conveying channel is formed between the extension plate 4 and the spacer plate 5, and an aisle is formed between the spacer plate 5 and the bottom of the fixed seat 1, and the conveyer belt 17 passes through the conveying channel and the aisle, and the fixed The upper end of seat 1 is provided with bump one 2 and bump two 3, and described bump one 2 is provided with drive motor 6, and the output shaft of described drive motor 6 is connected with crank one 7, and one end of described crank one 7 Rotationally connected with crank two 8, one end of said crank two 8 is rotatably connected with crank three 9, one end of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com