Impressing device on soap production line

A production line and soap technology, applied in the direction of cooling soap, embossing/polishing soap, etc., can solve problems such as low work efficiency, affecting the quality of finished soap products, and inability to replace molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

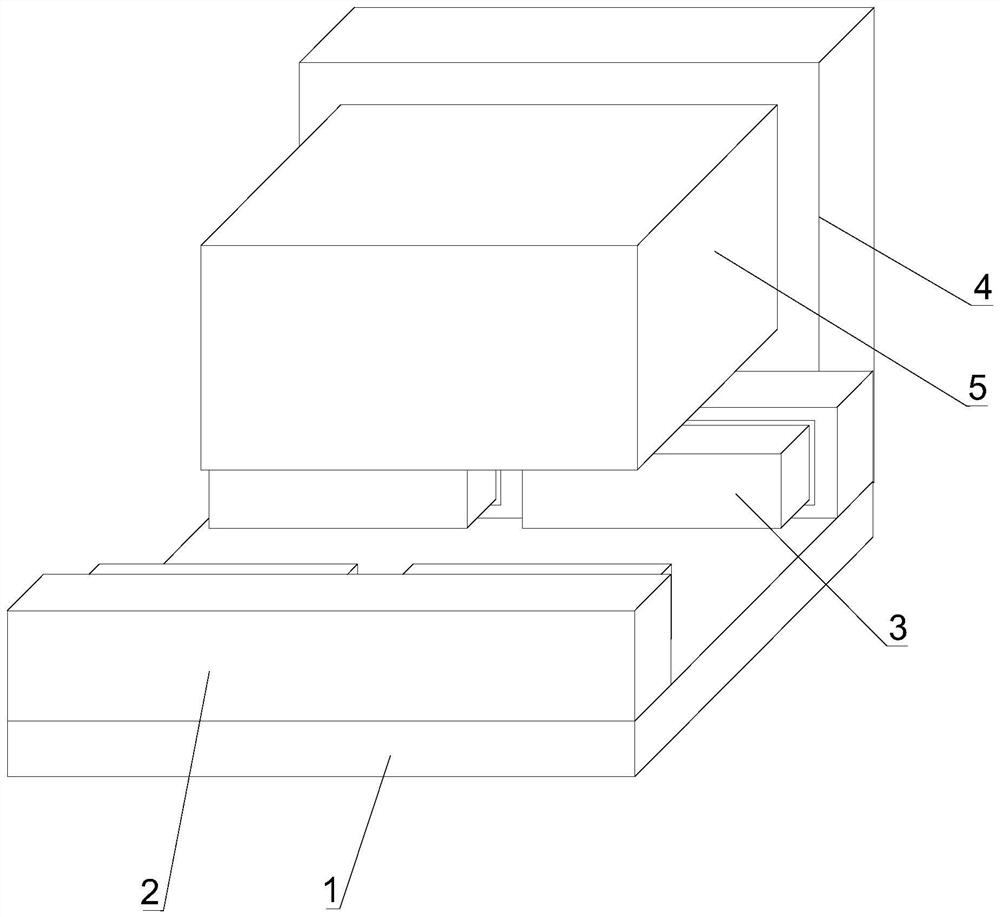

[0036] Such as Figure 1-6 Shown, the present invention provides a kind of embossing device on the soap production line, comprises soap production embossing device 1, lateral top plate 2, soap stop device 3, back side working plate 4 and soap embossing device shell 5, soap The side top plate 2 is detachably installed on the front and rear sides of the top of the production embossing device 1, and the soap limiter 3 is detachably installed on one side of the lateral top plate 2. The back side of the soap production embossing device 1 The backside working plate 4 is detachably installed on the top, and the soap embossing device shell 5 is detachably installed on the front outer surface of the backside working plate 4 .

[0037] In this embodiment, the cut soap is transported by the soap production embossing device 1, and the soap is limited in position by the soap limiting device 3, and then passed through the soap embossing device shell on the surface of the back side working p...

Embodiment 2

[0040] Such as Figure 1-6 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, a propeller 31 is arranged inside the left side of the soap limiting device 3, and the output end of the propeller 31 extends to the soap limiting device 3 On the outer surface of the right side of the soap limiter 3, a lap block 32 is fixedly connected on the outer surface of the right side of the soap limiting device 3, and an expansion plate 33 is detachably connected to the output end of the propeller 31, and the right side of the expansion plate 33 is on the upper side. An elastic shaft is arranged on the outer surface, and an opening and closing plate 34 is arranged on the outer surface of the elastic shaft, and an empty groove is arranged on the right outer surface of the unfolding plate 33, and a buffer wire is detachably connected to the inner surface of one side of the empty groove. 35. One end of the buffer wire one 35 is detachably connec...

Embodiment 3

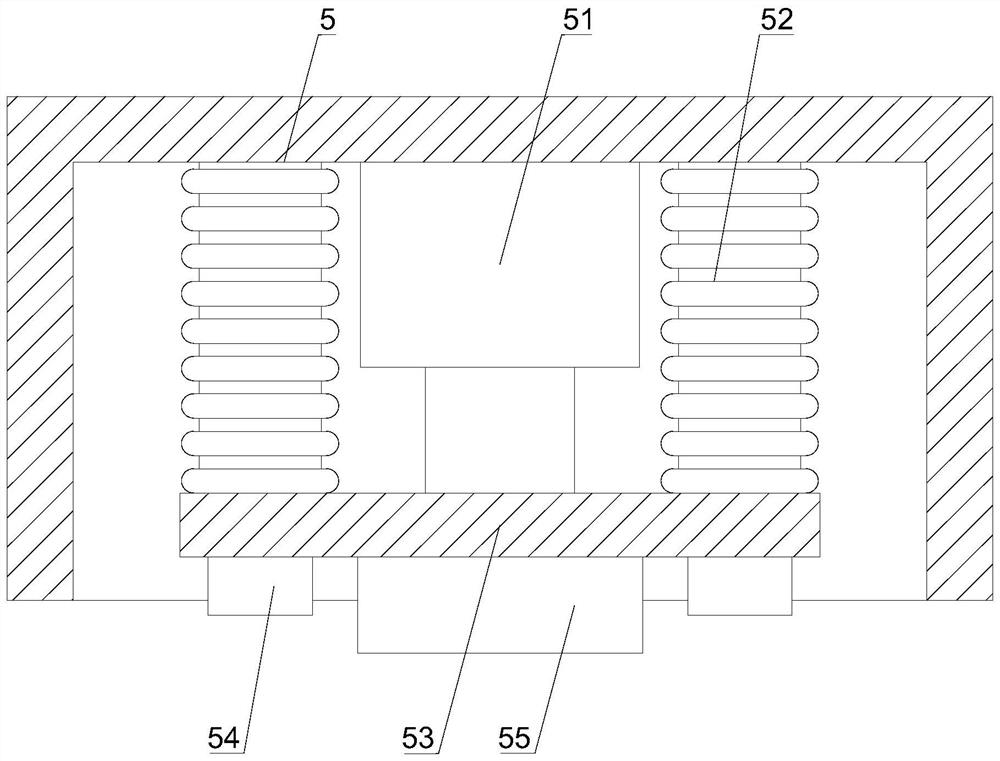

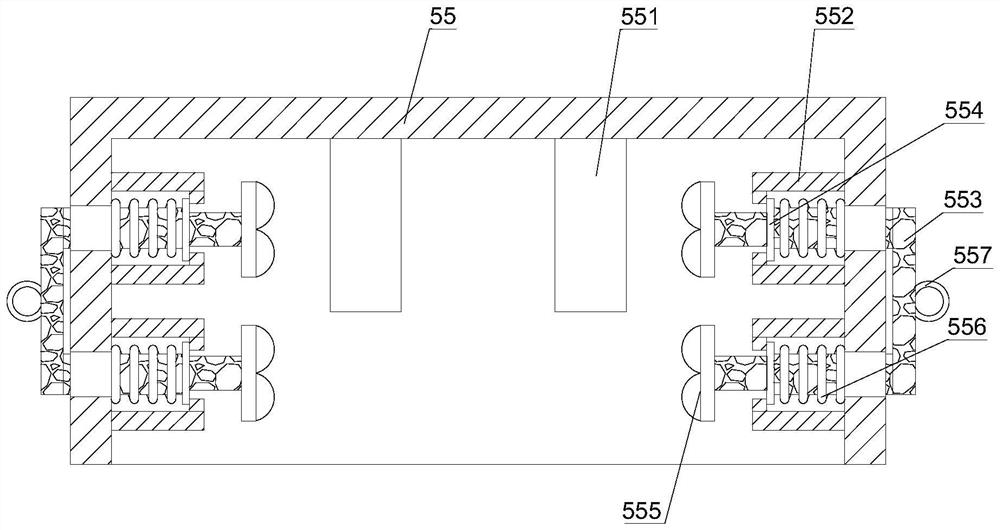

[0043] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the soap embossing device shell 5 includes a mold casing 55, and the top inner surface of the mold casing 55 is detachably installed with a snap-fit Limiting conductive rods 551, side vertical plates 552 are detachably installed on the inner surfaces of both sides of the mold casing 55, and C-shaped pull plates 553 are movably socketed on the outer surfaces of both sides of the mold casing 55, C-shaped One end of the pulling plate 553 extends to the inner surface of the mold casing 55, and the limit clamping plate 554 is arranged on the outer surface of the inner side vertical plate 552, and one end of the C-shaped pulling plate 553 is detachably connected with a soft extrusion. Pressing head 555, buffer pushing wire 556 is movably sleeved on the outer surface of inner side C-shaped pulling plate 553, and one side outer surface of limit clamping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com