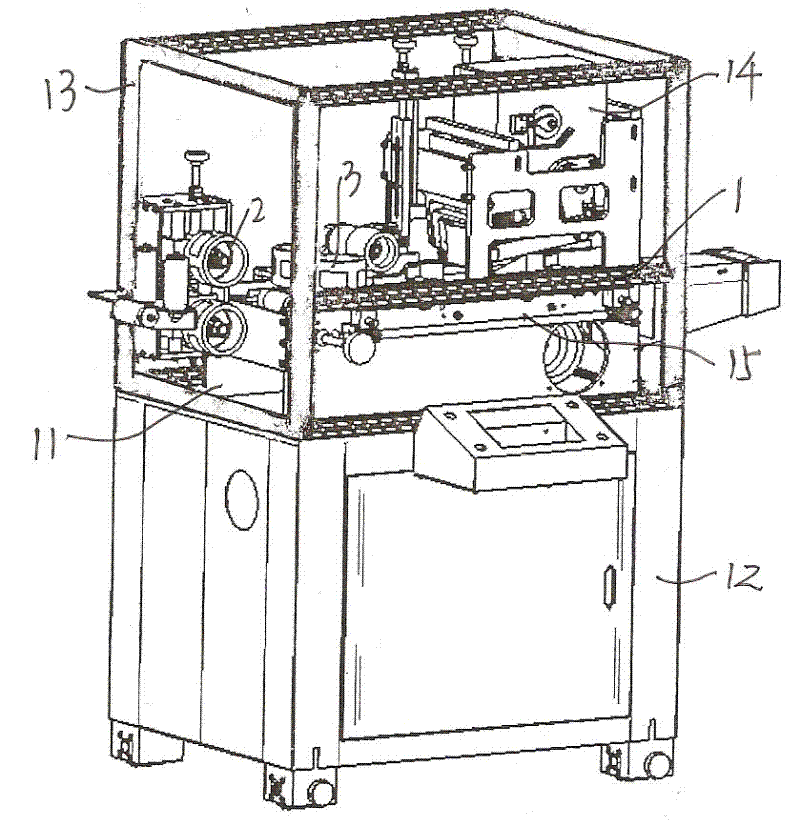

Four-side roll printing block cutting machine

A block cutting machine and rolling printing technology, which is applied in the direction of cutting soap, embossing/polishing soap, etc., can solve the problems of unsatisfactory work performance, complex structure, troublesome operation, etc., and achieve a light and simple overall structure, simple and convenient operation, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

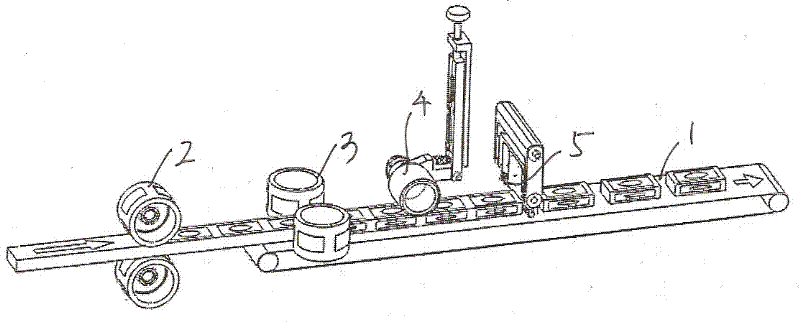

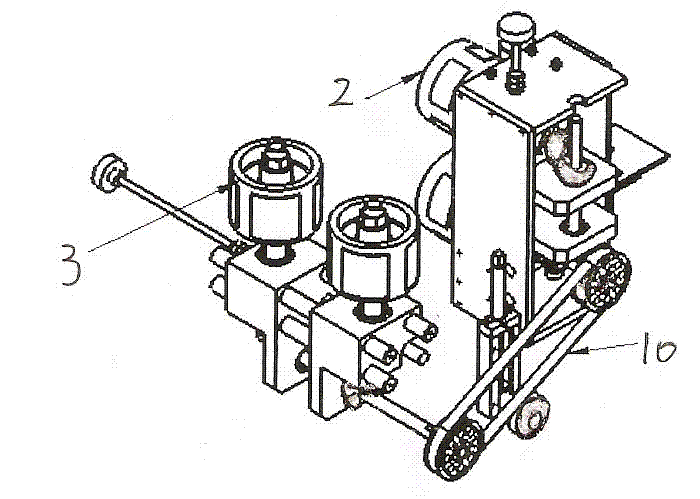

[0023] A four-sided roll printing block cutting machine, comprising a soap block conveying line 1, an upper and lower rolling die device 2 and a left and right rolling die device 3 are arranged in sequence near the soap block conveying line, and the upper and lower rolling die devices and the left and right rolling die devices It is equipped with an encoder that outputs pulse signals to the programmable controller during operation. After rolling the mold device left and right, it is equipped with a speed measuring wheel 4 for measuring the speed of the conveying line. The speed measuring wheel is set on the speed measuring wheel to output pulse signals to the programmable controller during operation. A speed measuring encoder, the cutter 5 that cuts the soap bar is set behind the speed measuring wheel; the programmable encoder controls the cutting speed of the cutter through the transmission system.

[0024] The transmission system includes a servo motor 6 connected to a progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com